Finishing mould for forming a glass article, such as a glass vial

A technology for processing molds and glass products, applied in the direction of glass blowing molds, etc., can solve the problems of not suitable for completely symmetrical demoulding, invisible sealing surface, and poor pattern.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

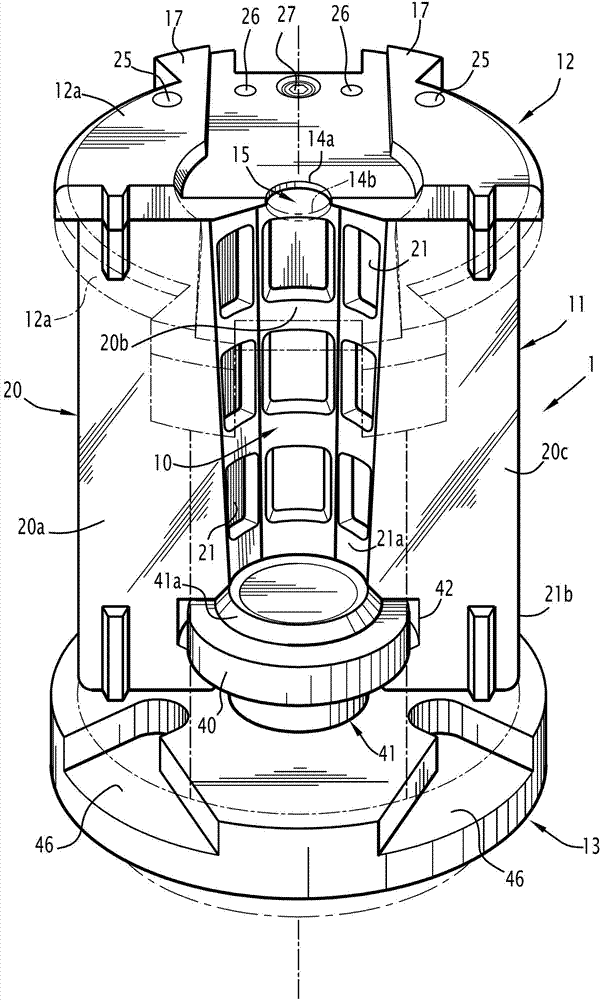

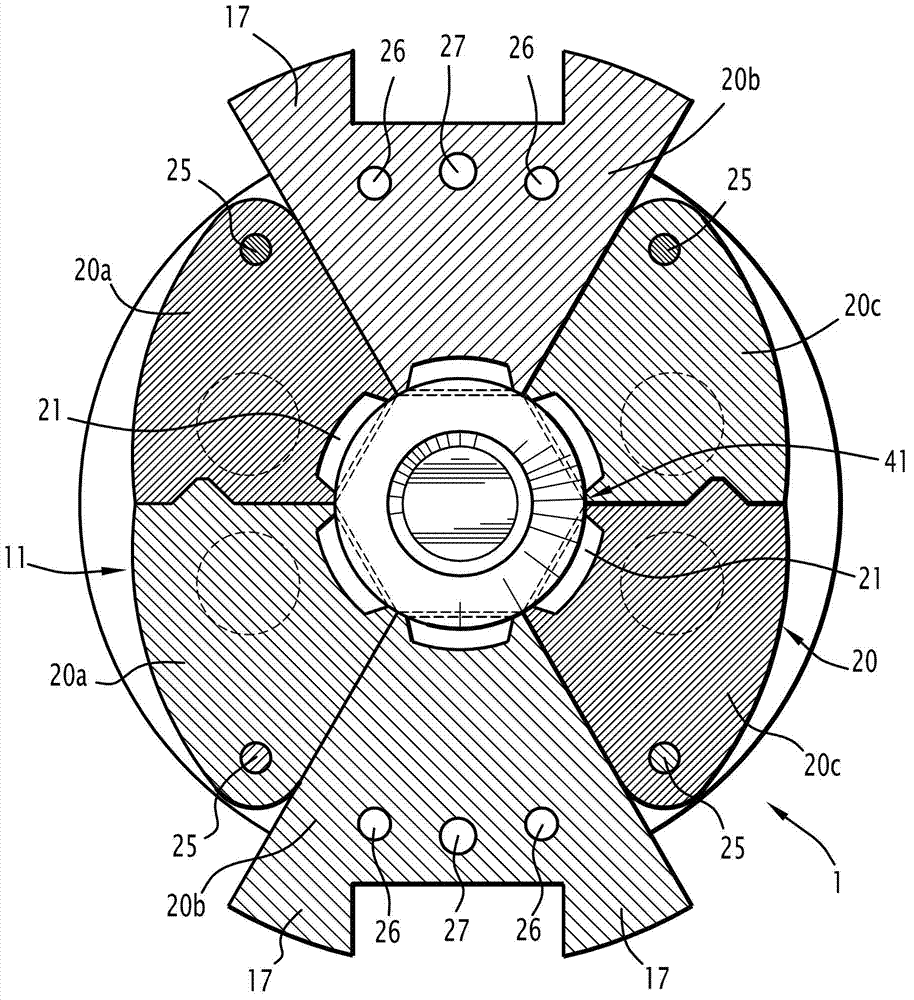

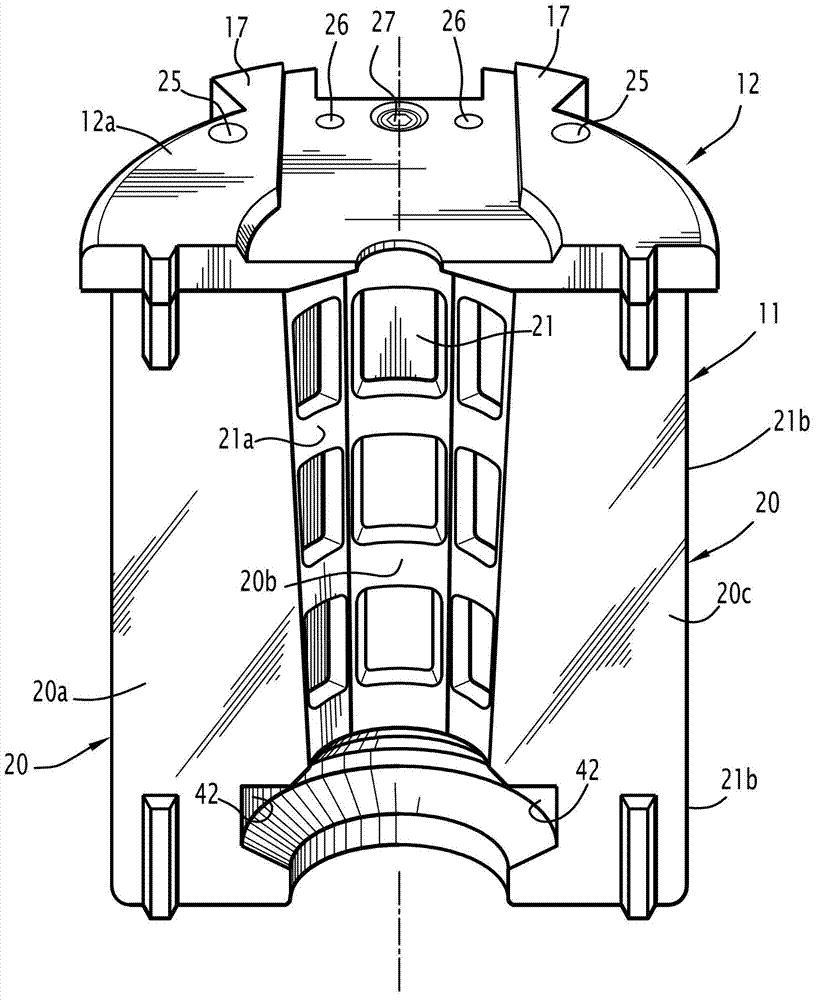

[0030] figure 1 with Figure 8 The diagram shows two implementations of processing molds, figure 1 The processing mold is indicated by the common mark 1, Figure 8 The processing mold is indicated by the common mark 2.

[0031] In the following description, components common to the two embodiments are denoted by the same symbols.

[0032] The processing molds 1 and 2 are designed to produce glass products, such as glass bottles, and preferably include at least one pattern of protrusions and / or depressions on their outer surface.

[0033] As an example, the processing molds 1 and 2 are designed to make the glass bottle have a general cylindrical shape and include a neck. The processing mold according to the present invention can also be designed to mold an oval, elliptical, square or hexagonal bottle body, or for example a star-shaped bottle body with six arms.

[0034] The processing die 1 or 2 includes a cavity 10 for receiving a parison not shown, preferably a shaped parison. The c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com