Water tower structure and transport packaging method thereof

A packaging method and a water tower technology, which are applied in the field of transportation and packaging of the water tower structure, can solve the problems of difficulty in stacking packaging, the water tower is easy to loosen, and increase the cost, and achieve the effect of stabilizing the transportation stack structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

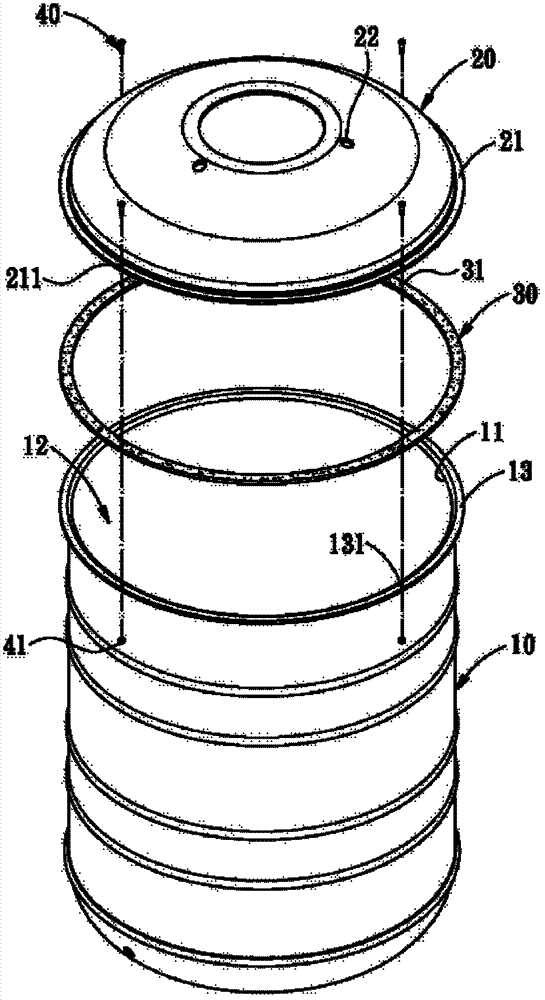

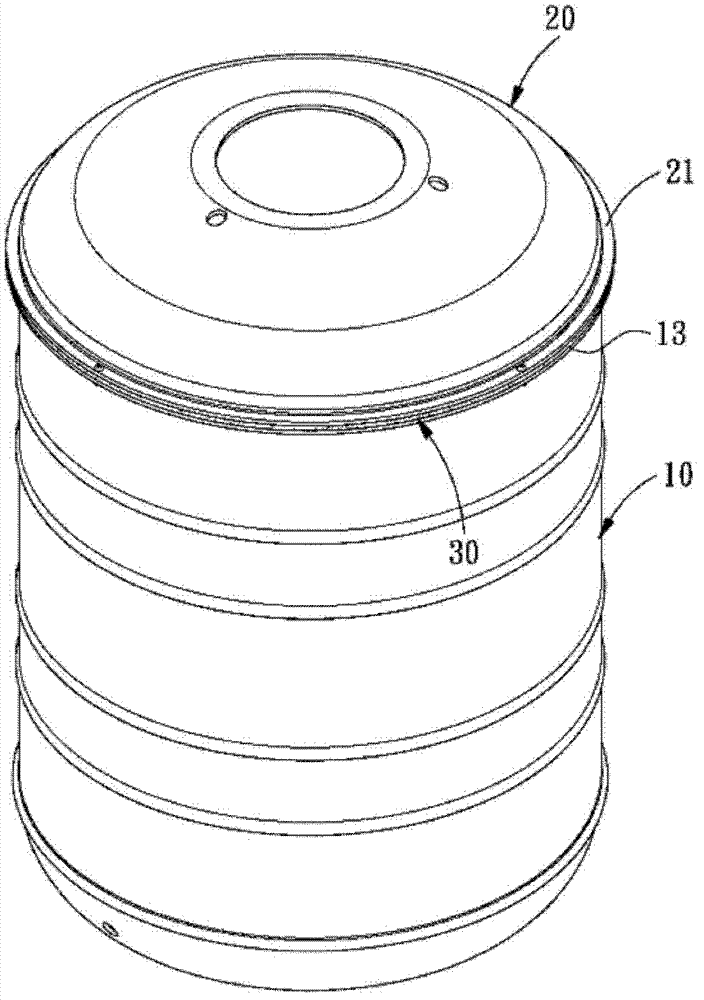

[0046] Such as figure 1 , figure 2 with Figure 3a As shown, an embodiment of the water tower structure of the present invention has a plurality of water towers, and each of the water towers includes a tower body part 10 and a cover part 20;

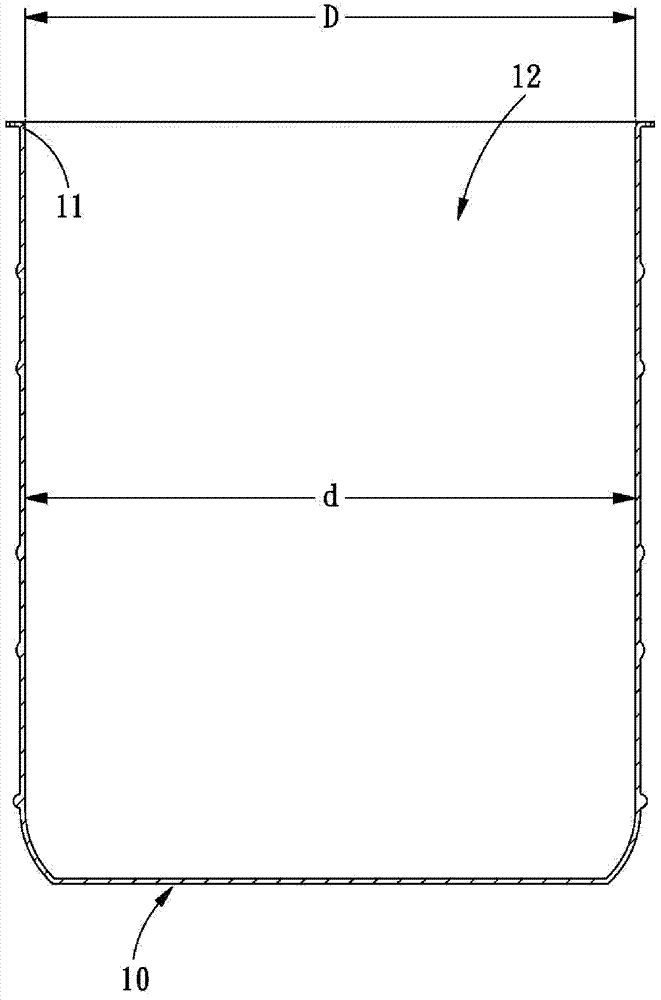

[0047] The tower body part 10 has an opening 11 in a cylindrical structure, and the tower body part 10 is concavely provided with an accommodating space 12 from the opening 11 to the inside, and the inner diameter D of the opening is equal to or close to the inner diameter d of the accommodating space, and The tower body part 10 is provided with a joint part 13 on the peripheral side of the opening 11;

[0048] The cover 20 has a sheet structure and is combined with the opening 11 of the tower body 10 to form a water tower. The periphery of the cover 20 is provided with a combination part 21 corresponding to the combination part 13 of the tower body 10;

[0049] Let the multiple water towers be defined as a large size tower body 10a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com