Preparation method of high-hydrogen biological fuel oil

A fuel oil and biological technology, which is applied in the preparation of liquid hydrocarbon mixtures, biological raw materials, petroleum industry, etc., can solve the problems of rising market prices of plant raw materials, not being established as general fuel oil, and failing to save fuel, etc. The risk of oil import, the effect of saving foreign exchange reserves and reducing cost problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

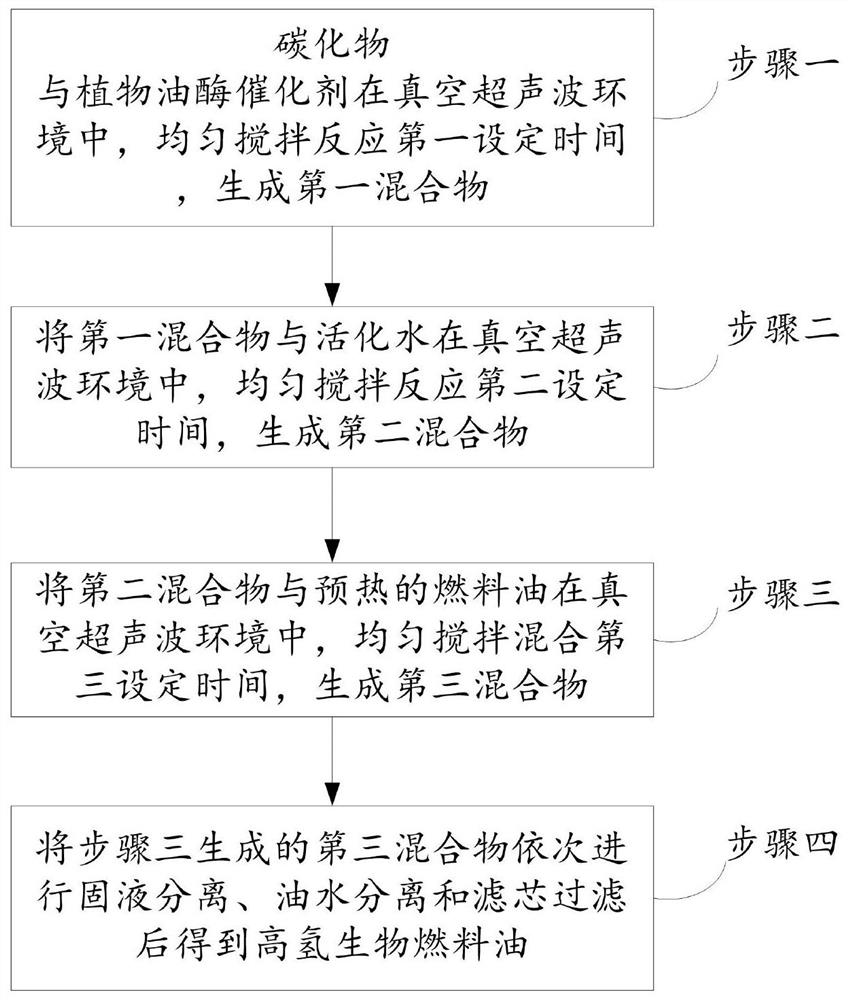

[0032] Such as figure 1 As shown, the embodiment of the present invention provides a kind of preparation method of high-hydrogen biofuel oil, comprising:

[0033] Step 1: Carbide and vegetable oil enzyme catalyst are uniformly stirred and reacted for a first set time in a vacuum ultrasonic environment to generate a first mixture;

[0034] Step 2, the first mixture and activated water are uniformly stirred and reacted for a second set time in a vacuum ultrasonic environment to form a second mixture;

[0035] Step 3, uniformly stirring and mixing the second mixture and the preheated fuel oil in a vacuum ultrasonic environment for a third set time to generate a third mixture;

[0036] In step four, the third mixture generated in step three is subjected to solid-liquid separation, oil-water separation, and filter element filtration in sequence to obtain high-hydrogen biofuel oil.

[0037] In the above method, the carbide may be coconut shell carbide or bamboo, and the particle s...

Embodiment 1

[0062] The embodiment of the present invention provides a method for preparing high-hydrogen biofuel oil, comprising:

[0063] Step 1, the carbide and the vegetable oil enzyme catalyst are stirred and reacted uniformly for 5 minutes in a vacuum ultrasonic environment at a temperature of 45° C. according to a volume ratio of 1:5 to form a first mixture;

[0064] Step 2: Mix the first mixture and activated water in a volume ratio of 1:8 in a vacuum ultrasonic environment, and at a temperature of 48°C, uniformly stir and react for 8 minutes to form a second mixture;

[0065] Step 3: Stir and mix the second mixture and the preheated diesel oil in a volume ratio of 45:55 in a vacuum ultrasonic environment at a temperature of 50°C for 10 minutes to form a third mixture;

[0066] In step four, the third mixture generated in step three is subjected to solid-liquid separation, oil-water separation, and filter element filtration in sequence to obtain high-hydrogen biofuel oil.

Embodiment 2

[0068] The embodiment of the present invention provides a method for preparing high-hydrogen biofuel oil, comprising:

[0069] Step 1: Carbide and vegetable oil enzyme catalyst are stirred and reacted uniformly for 10 minutes in a vacuum ultrasonic environment at a temperature of 48° C. according to a volume ratio of 1:5 to form a first mixture;

[0070] Step 2: Mix the first mixture and activated water in a volume ratio of 1:8 in a vacuum ultrasonic environment at a temperature of 50°C and uniformly stir for 5 minutes to generate the second mixture;

[0071] Step 3: Stir and mix the second mixture and the preheated diesel oil in a volume ratio of 45:55 in a vacuum ultrasonic environment at a temperature of 45°C for 8 minutes to form a third mixture;

[0072] In step four, the third mixture generated in step three is subjected to solid-liquid separation, oil-water separation, and filter element filtration in sequence to obtain high-hydrogen biofuel oil.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com