Cleaning system, cleaning device, and method of using cleaning device

一种清洗装置、入口的技术,应用在使用液体的清洁方法、清洁方法和用具、化学仪器和方法等方向,能够解决管路阻塞、弯管P3阻塞等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

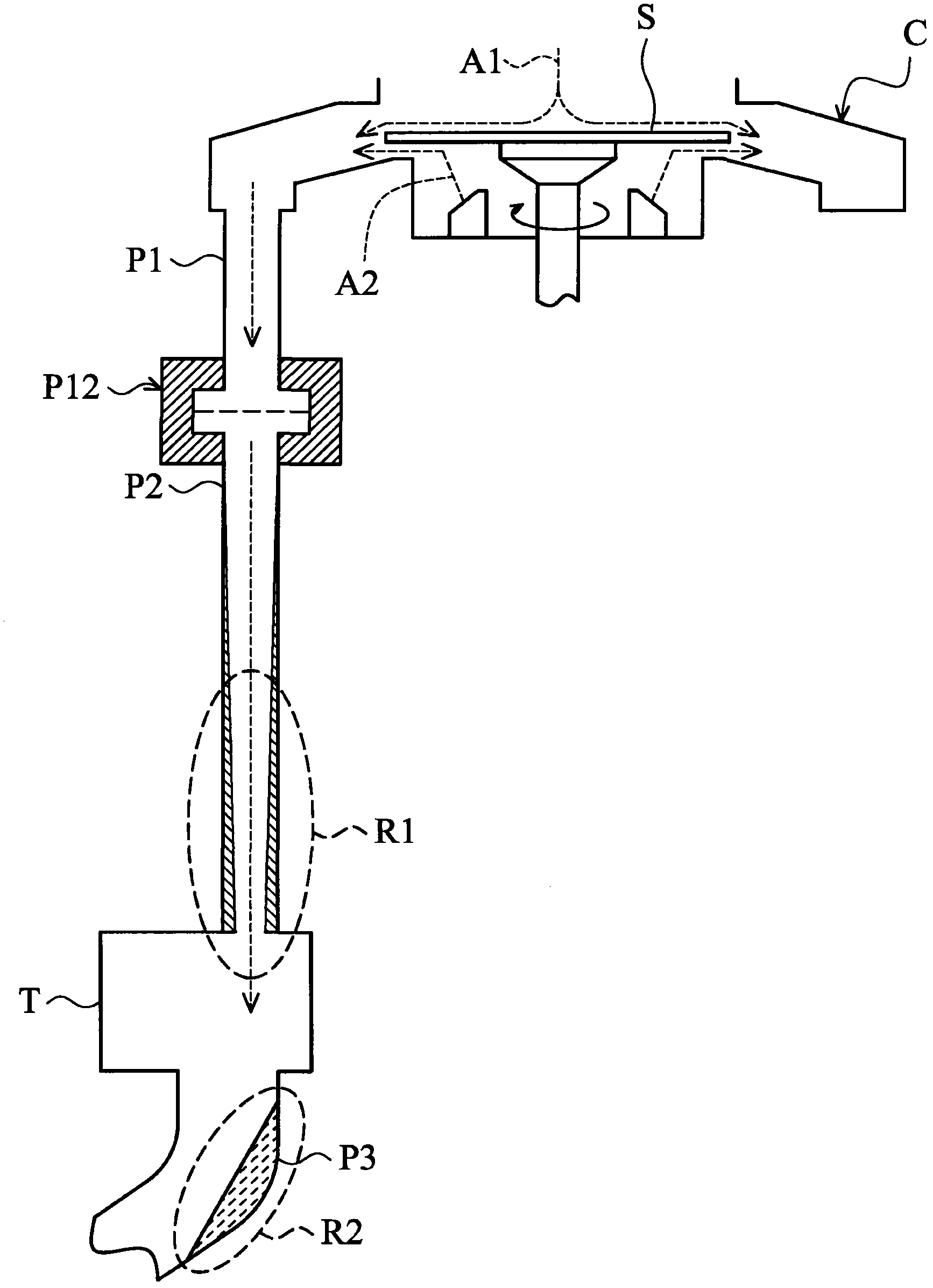

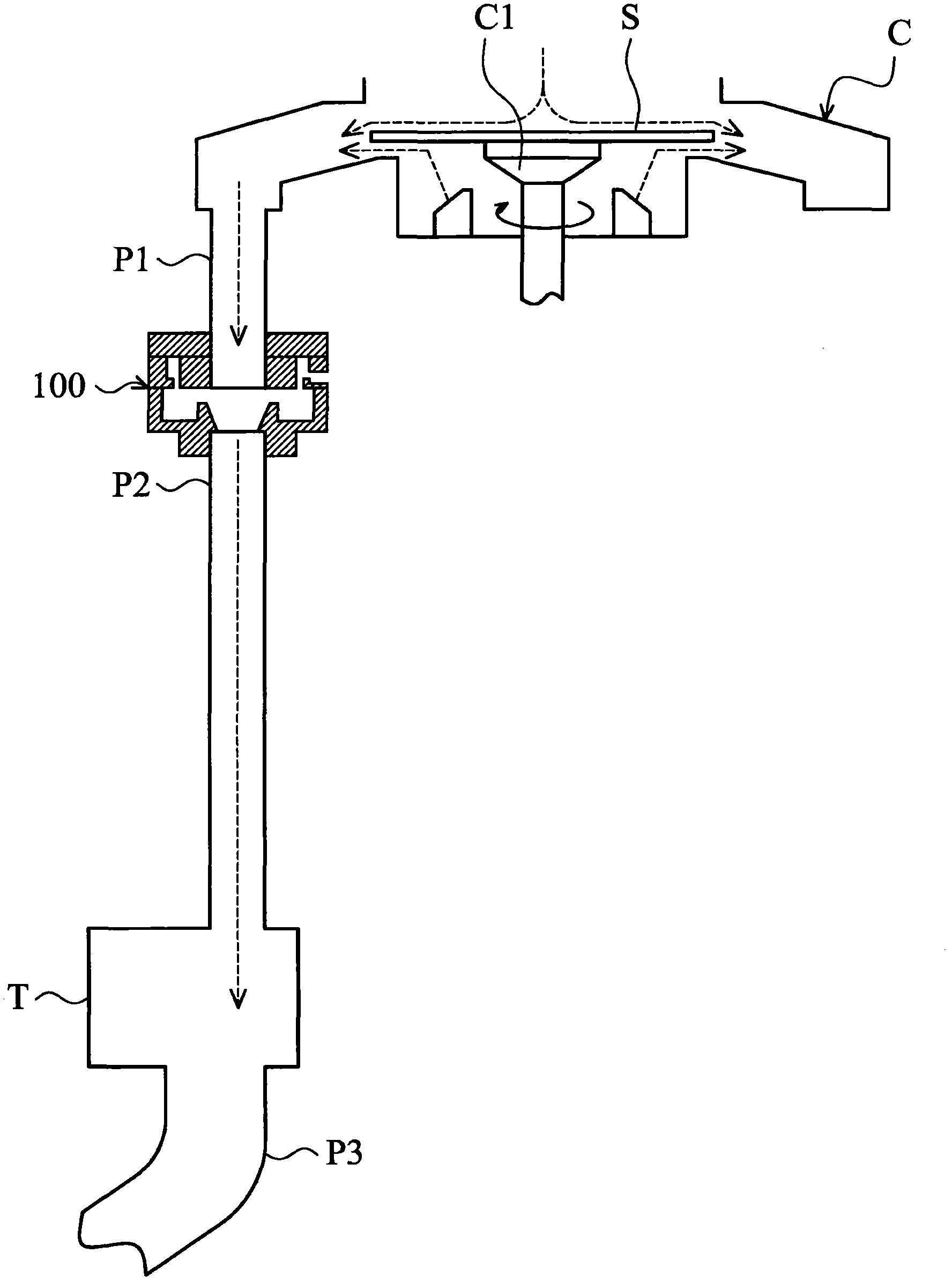

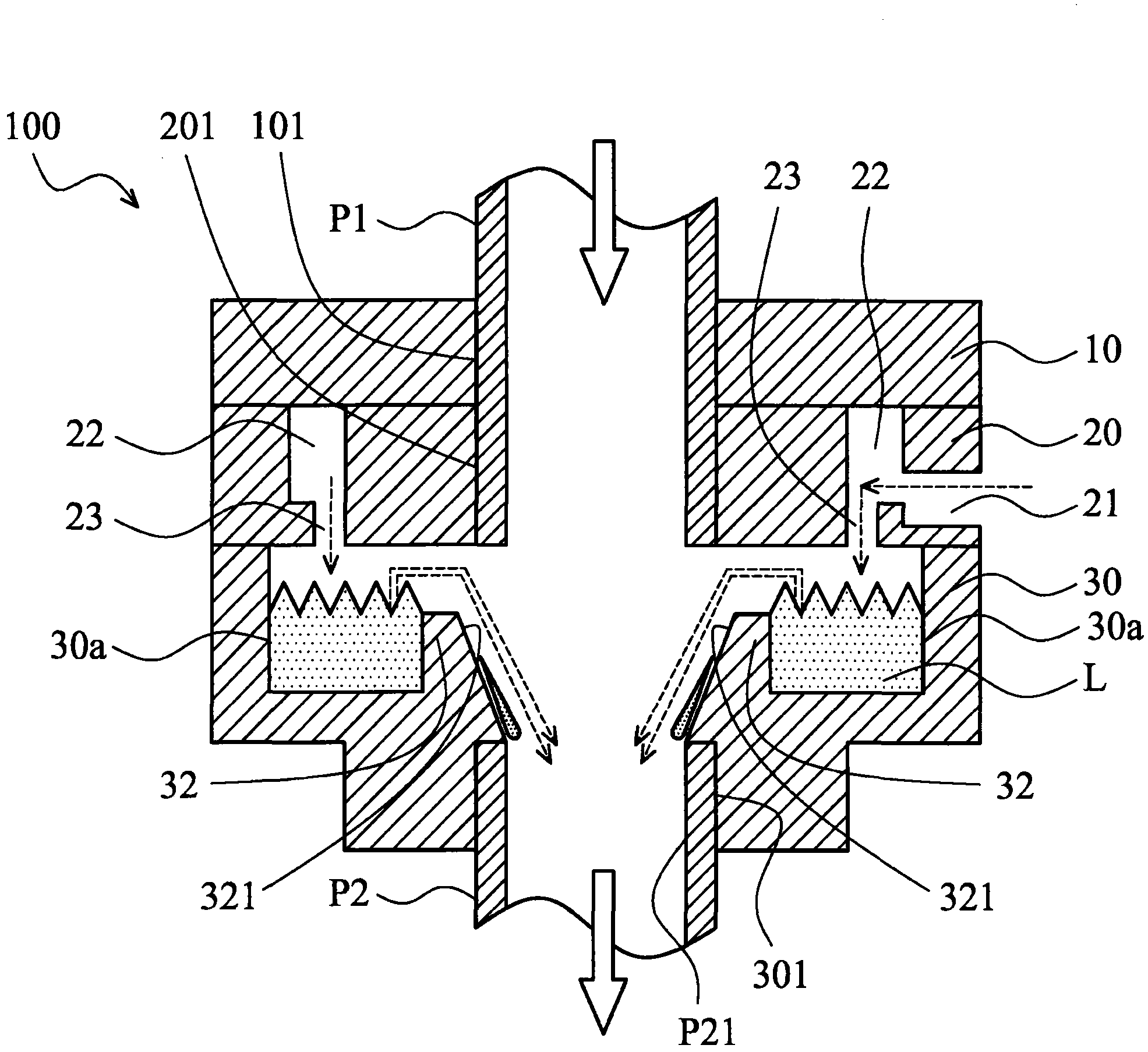

[0058] Please refer to figure 2 , the cleaning device 100 of an embodiment of the present invention is connected to the discharge pipe P1 and the liquid discharge pipe P2 of the spin coating equipment C, wherein the aforementioned cleaning device 100 can be connected with figure 1 The pipe clamp device P12 in is installed at the same position, but its installation position is not limited thereto. In a semiconductor process, such as a photolithography process, a substrate S is mounted on the chuck C1 of a spin coating device C. When the substrate S starts to rotate, it contains photoresist and cleaning agent (such as photoresist thinner). ) will be washed away from the surface of the substrate S and discharged through the discharge pipe P1. In this embodiment, the aforementioned fluid flows from the cleaning device 100 into the drain tank T through the drain pipe P2, and the discharged liquid flows into the pipeline equipment system (not shown) sequentially through the elbow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com