Torque tool

A tool and torque technology, applied in the field of corner wrench/torque wrench, to avoid the danger of confusion, prevent mechanical damage, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

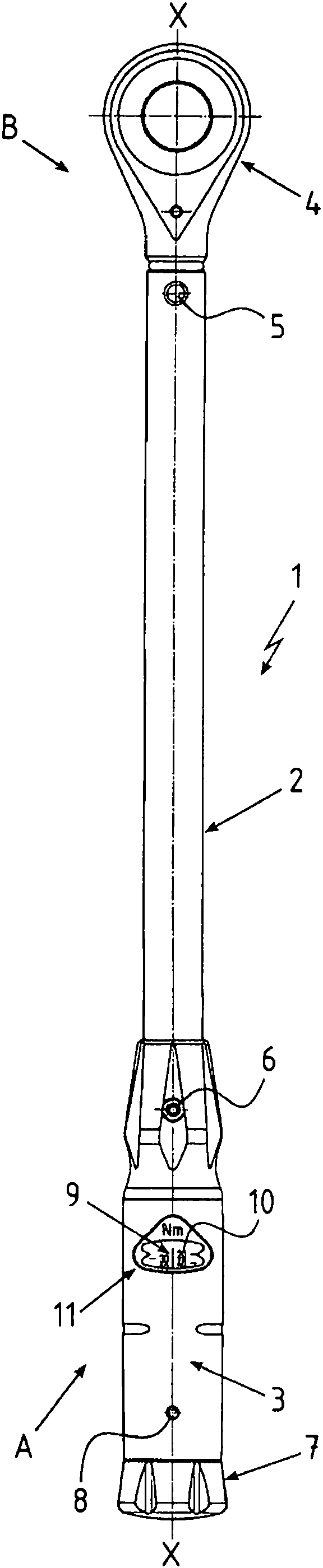

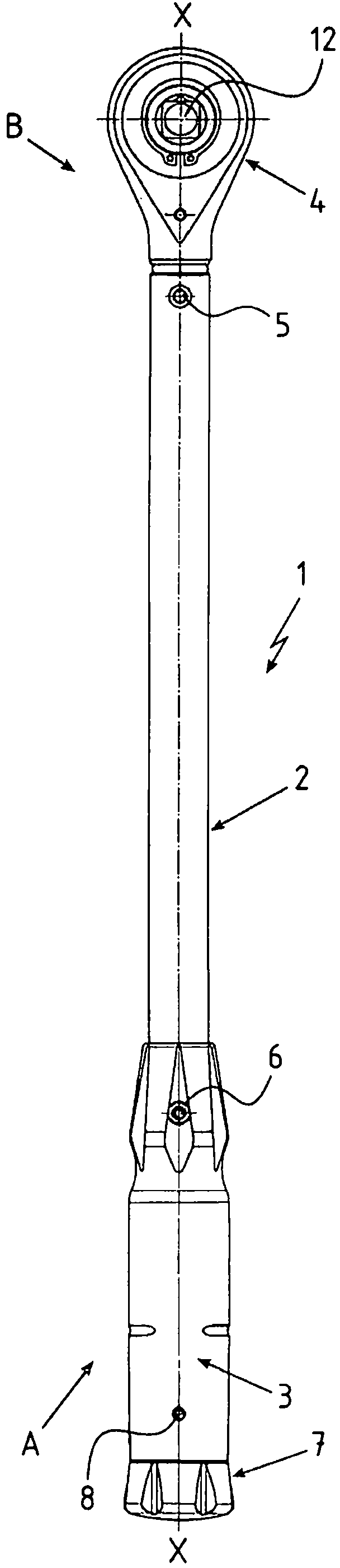

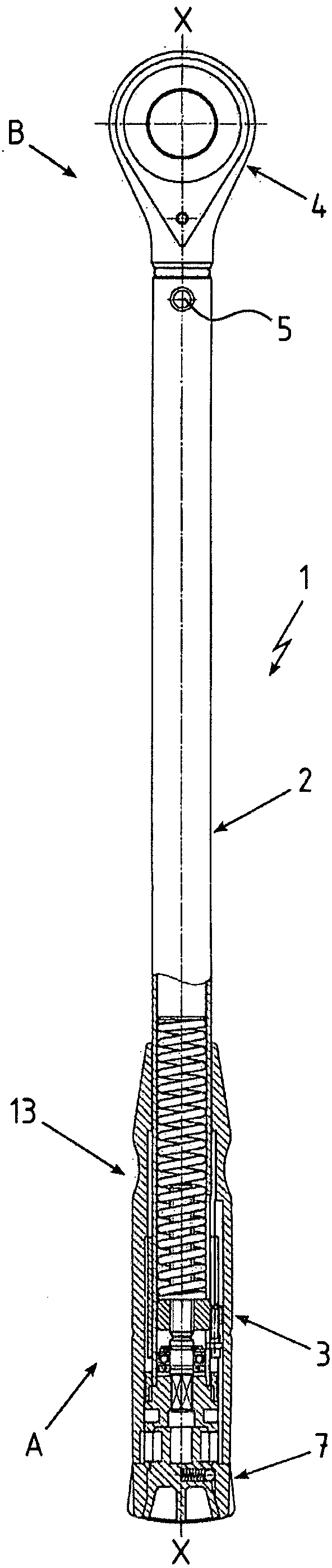

[0048] figure 1 A torque tool 1 according to the invention is shown having a tool shaft 2 and a handle 3 arranged on an end section A of the tool shaft 2 . A tool head 4 is arranged on the end section B of the tool shaft 2 opposite the handle 3 . The tool bit 4 leads into a shank, not shown in detail here, by means of which the tool bit 4 is inserted into the end section B of the tool shaft 2 and secured by a cotter pin 5 . In principle the cotter pin 5 can also be a detachable connecting element.

[0049] The handle 3 is fastened to the end section A of the tool shaft 2 via a connecting element 6 . An adjusting knob 7 is arranged on the free end of the handle 3 . The adjusting knob 7 is mounted rotatably about the longitudinal direction X of the tool shaft 2 inside the handle 3 and is prevented from being pulled out of the handle 3 by means of the connecting element 8 . In the central area of the handle 3 is arranged a display element 9 by means of which the correspondi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com