Temperature compensating capacitor dielectric with linear change rate of capacity and temperature and preparation method of temperature compensating capacitor dielectric

A technology of capacitor dielectric and capacity temperature change rate, applied to inorganic insulators, ceramics, etc., can solve the problems of high sintering temperature and high cost of scale, and achieve the effects of reduced dielectric loss, low price, and low temperature coefficient of resonance frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] A method for preparing a temperature-compensated capacitor medium with a linear capacity temperature change rate, comprising the steps of:

[0027] 1. Calcining barium titanate at 1100-1150°C for 1.5-2h;

[0028] 2. Proportioning niobium oxide and nickelous oxide according to the molar ratio of 1:1, weighing, mixing by ball milling, and drying. After drying, the block is passed through a 40-80 mesh standard sieve and calcined at 850-1150°C to obtain Niobium-nickel compounds;

[0029] 3. According to parts by weight, 42-53 parts of zinc oxide; 10-18 parts of boric acid; 12-24 parts of silicon dioxide; After water quenching, grinding and drying through a 325-mesh standard sieve to obtain Zn-B-Ba-Si glass powder;

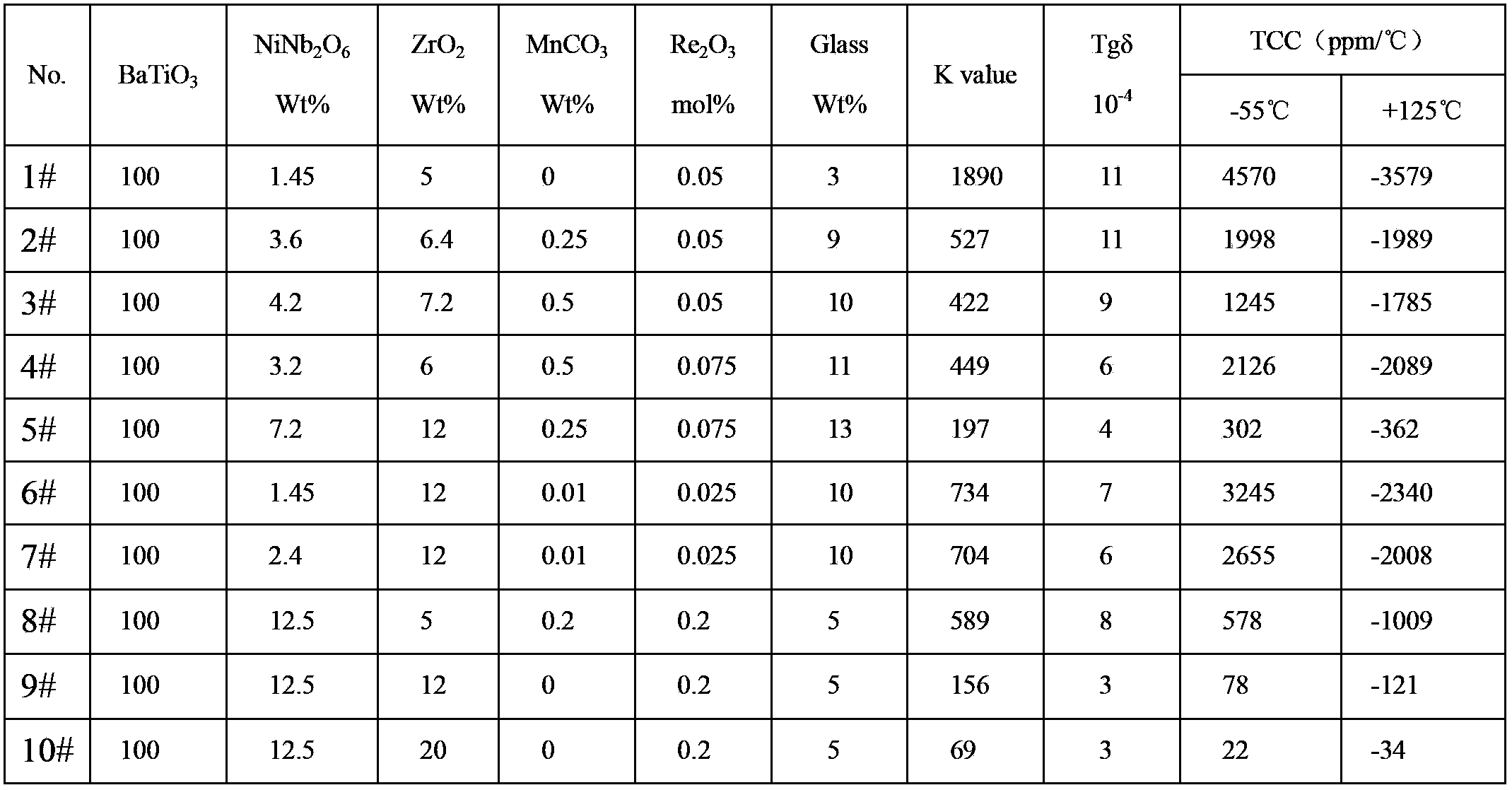

[0030] 4. With 100 parts by weight of barium titanate as the base material, the following components are added: niobium nickel compound 1.45-12.5wt%, zirconia 5-20wt%, manganese carbonate 0-0.2wt%, rare earth oxide 0.025-0.2mol %, Zn-B-Ba-Si glass 3-10wt%, us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com