Anti-high-overload integrated circuit

An integrated circuit and high-resistance technology, which is applied in the field of assembly structures, can solve the problems of hybrid integrated circuit substrates easy to fall off, substrates with low resistance to high and overload levels, etc., achieve simple substrate support and protection methods, improve the level of high and overload resistance, and are strong and practical sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

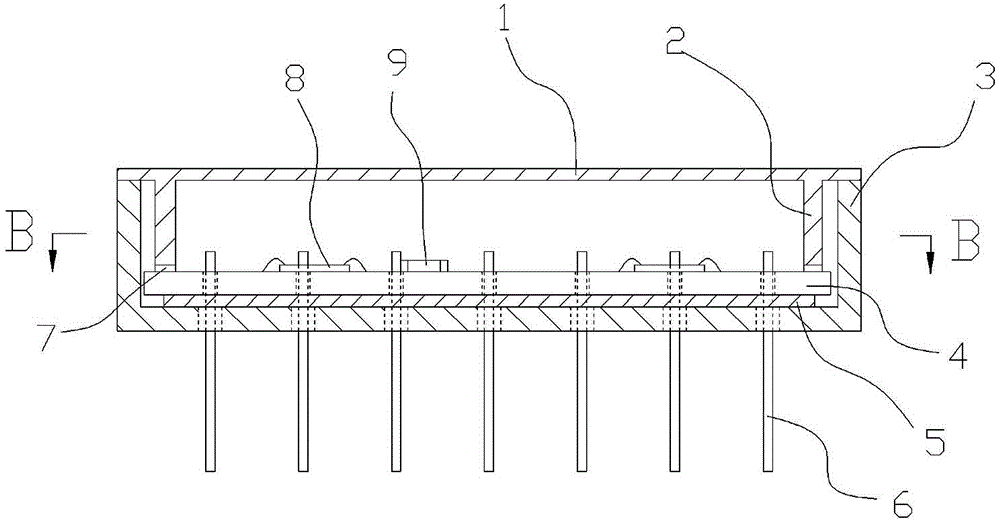

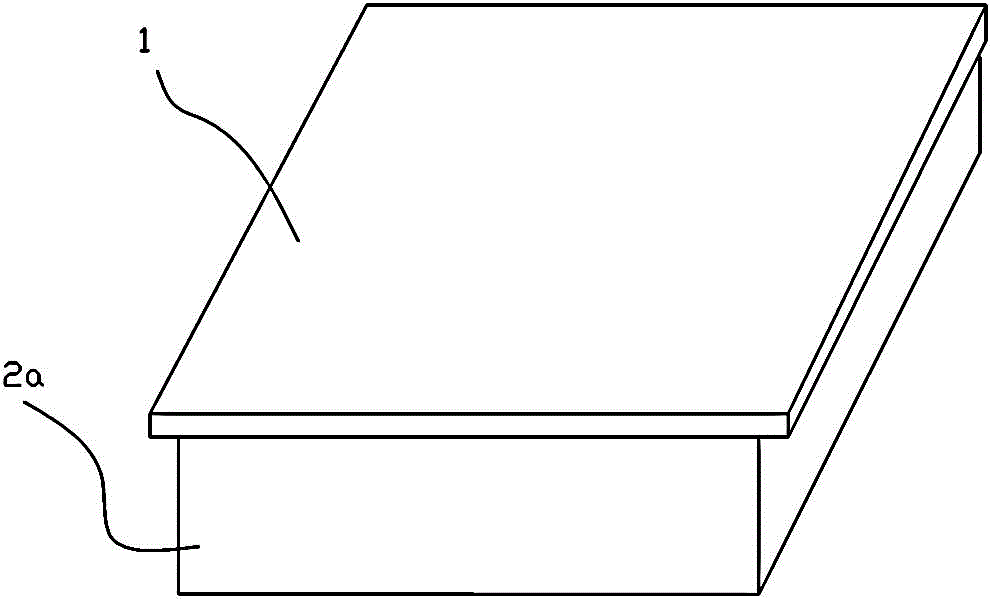

[0013] Such as figure 1 As shown, a high-overload-resistant integrated circuit provided by the present invention includes a housing 3, and the bottom surface of the housing 3 is assembled with a substrate 4 through insulating glue (or other assembly materials, such as solder, etc.) 5, and a chip 8 is arranged in the substrate 4. For circuit components such as the device 9, the substrate 4 is provided with electrodes 6 passing through the bottom surface of the housing. A sealing cover 1 is provided at the upper end of the housing, and a support 2 is provided on the side of the sealing cover extending toward the inner cavity of the housing, and the support 2 forms a pressing and positioning fit with the substrate. An insulating glue 7 is provided between the bottom surface of the support member 2 and the substrate to be in contact, and the support structure and the substrate can be effectively bonded by curing.

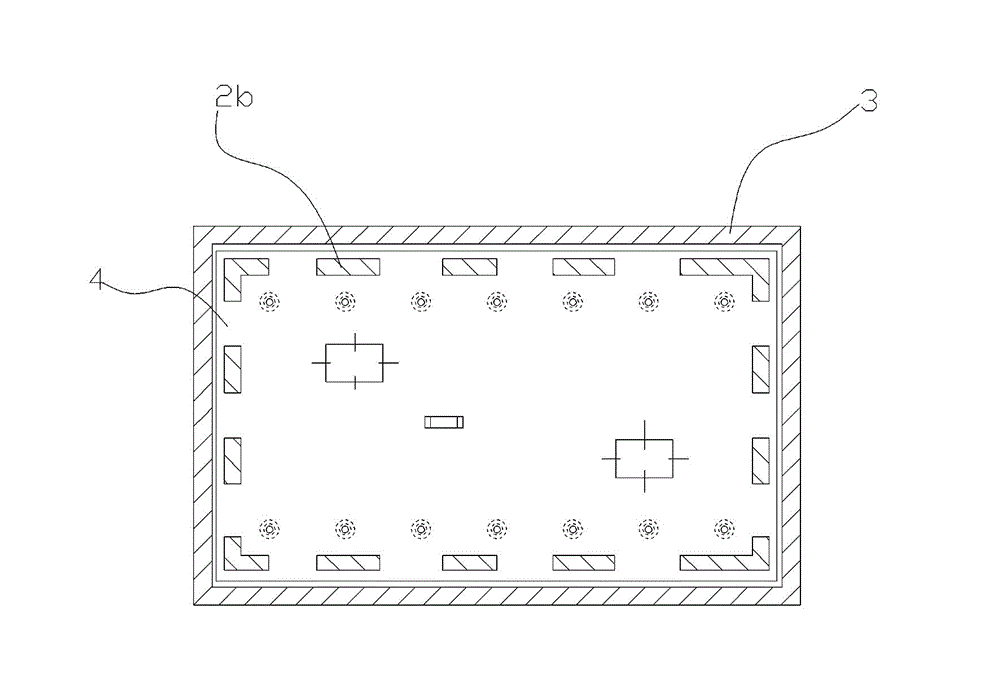

[0014] Such as figure 2 As shown, the supporting member can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com