Stretch-bending straightener

A technology of stretching, bending, straightening and equipment, which is applied in the direction of metal processing equipment, manufacturing tools, rolling mill control devices, etc., to achieve the effect of eliminating residual waviness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

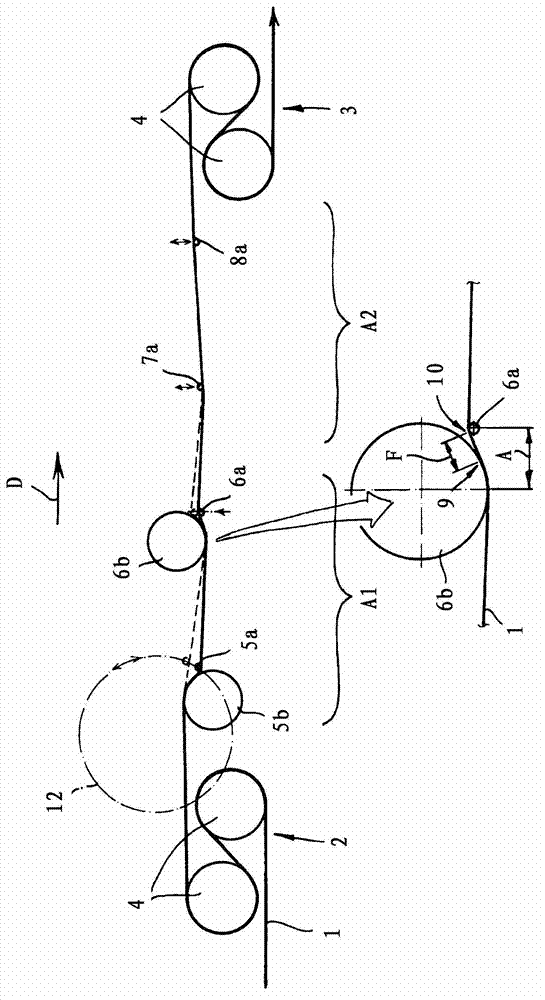

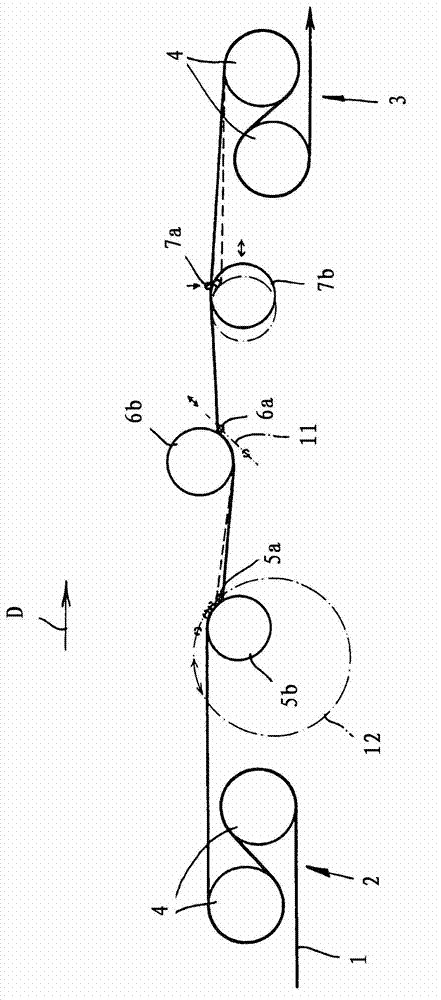

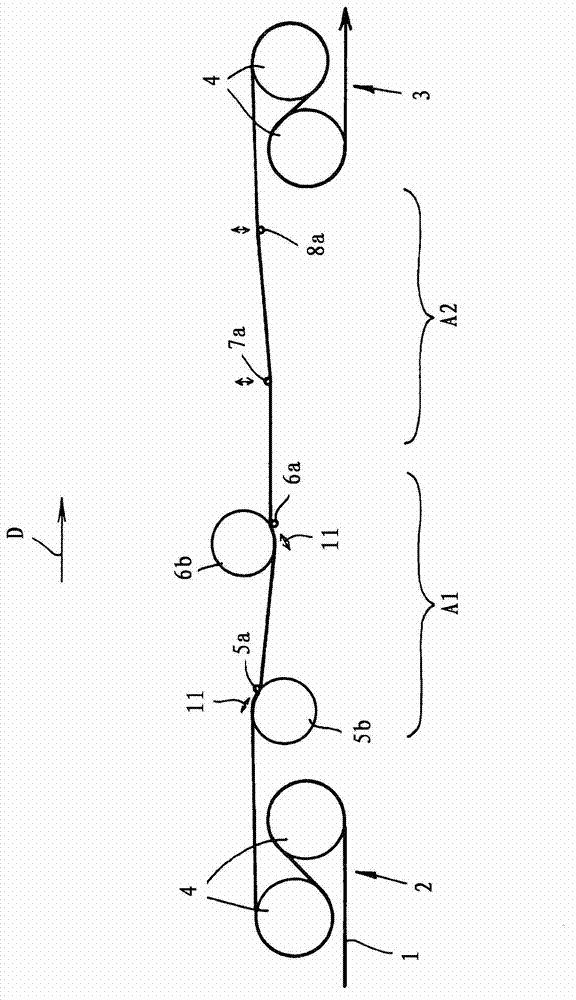

[0031] The figures each show a stretch-bend straightening device for stretch-bend straightening of a metal strip 1 . This stretch-bending straightening device has in its basic structure an entry pinch roll set 2 and an exit pinch roll set 3 as well as straightening rolls 5 a , 6 a arranged between said pinch roll sets 2 , 3 , 7a, 8a. The entry pinch roll set 2 with pinch rolls 4 can be designed as a braking roll set, while the exit pinch roll set 3 with pinch rolls 4 can be designed as a tension roll set. The strip travel direction D extends horizontally or substantially horizontally.

[0032] Tensile stresses can be generated in the metal strip 1 by means of the set of clamping rollers 2 , 3 , but are less than the elastic limit of the strip material. The strip is bent alternately in the plastic or elastoplastic range around the straightening rollers 5 a to 8 a and is then stretched plastically and thus elongated. In this case, each straightening roller 5 a , 6 a , 7 a , 8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com