High-power vertical-shaft multiple wind wheel group combined type wind power generating tower wheel

A technology with vertical shafts and multiple wind wheels, which is applied to wind turbine components, wind turbines at right angles to the wind direction, and wind turbines. The effect of poor self-start performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

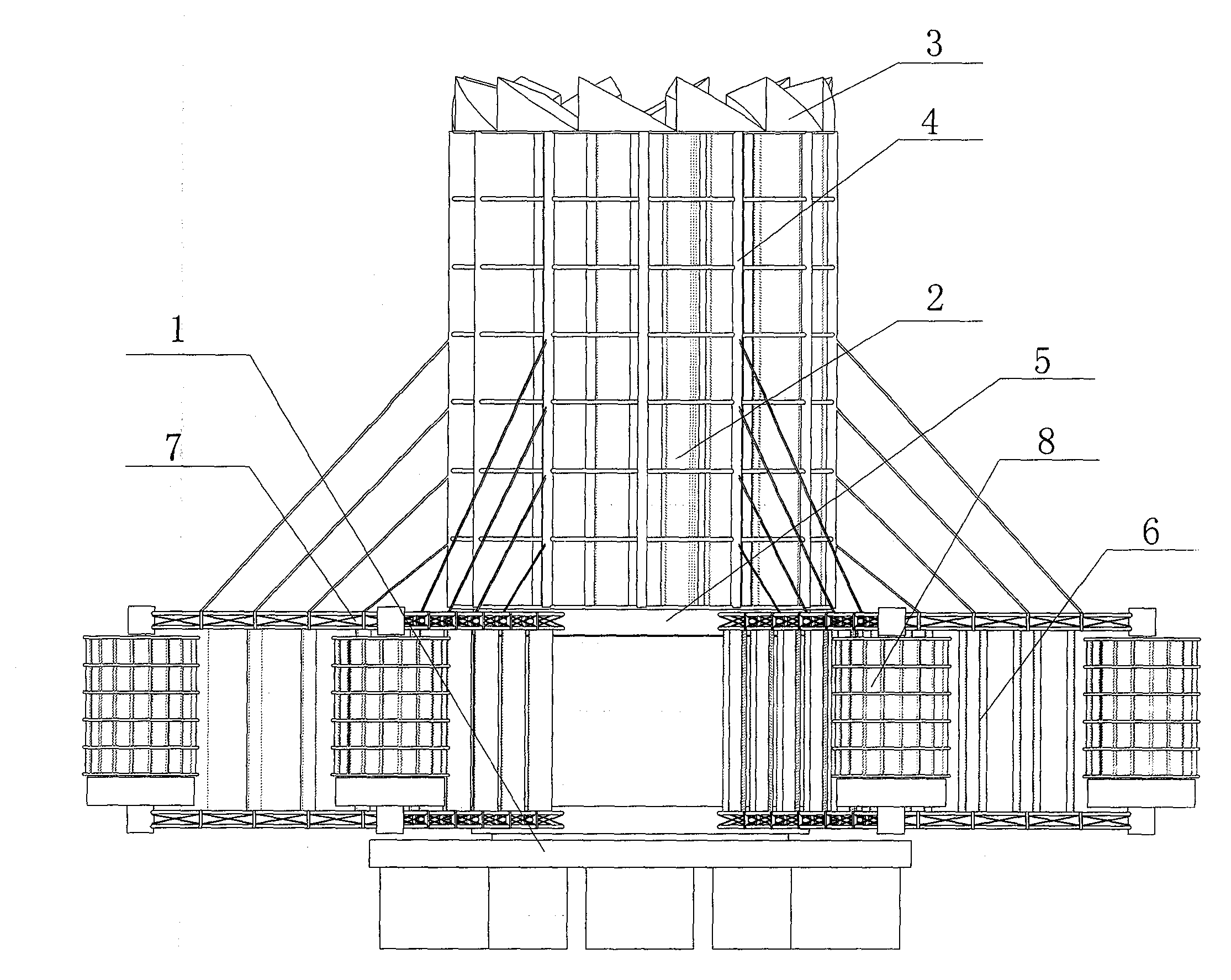

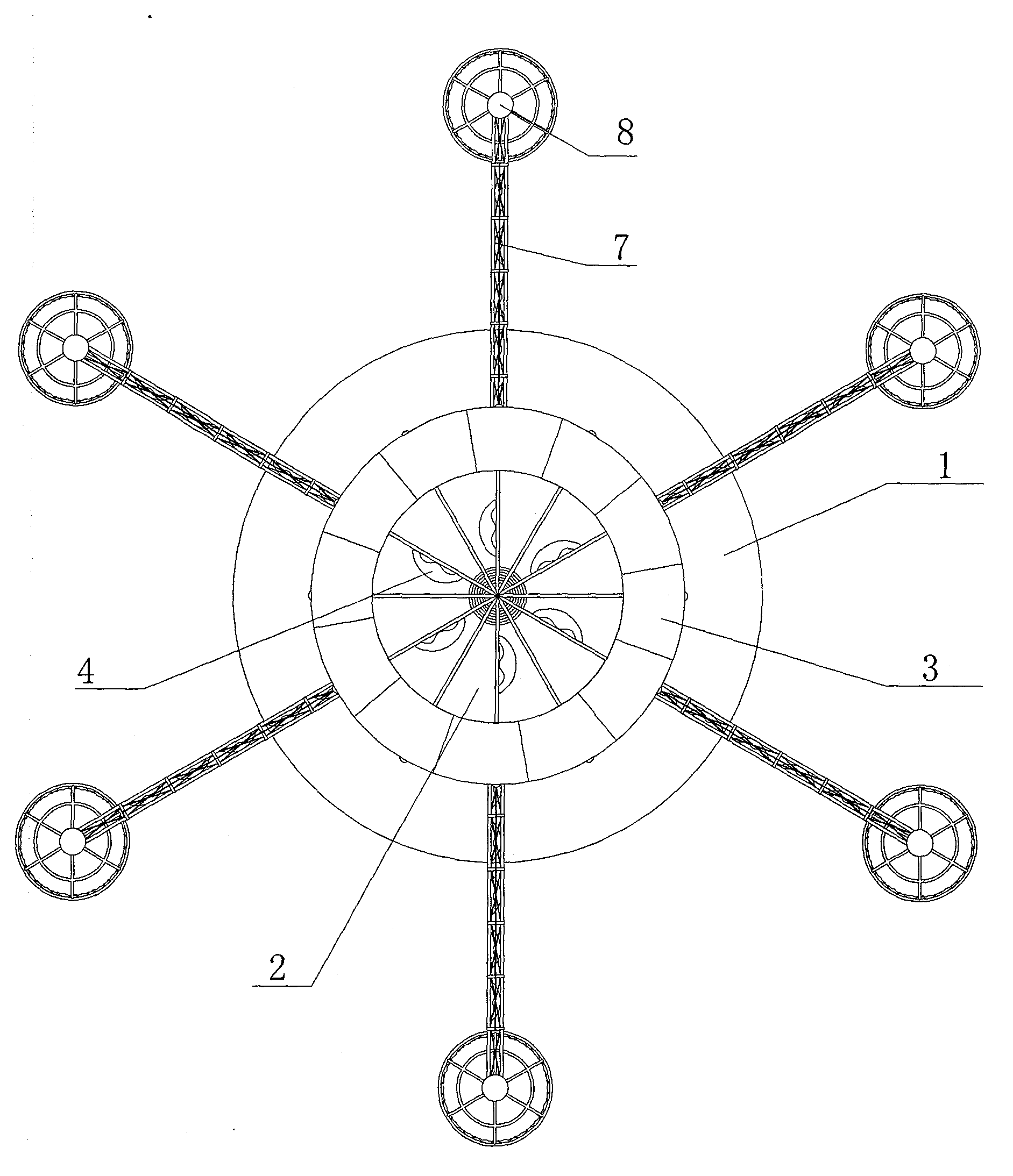

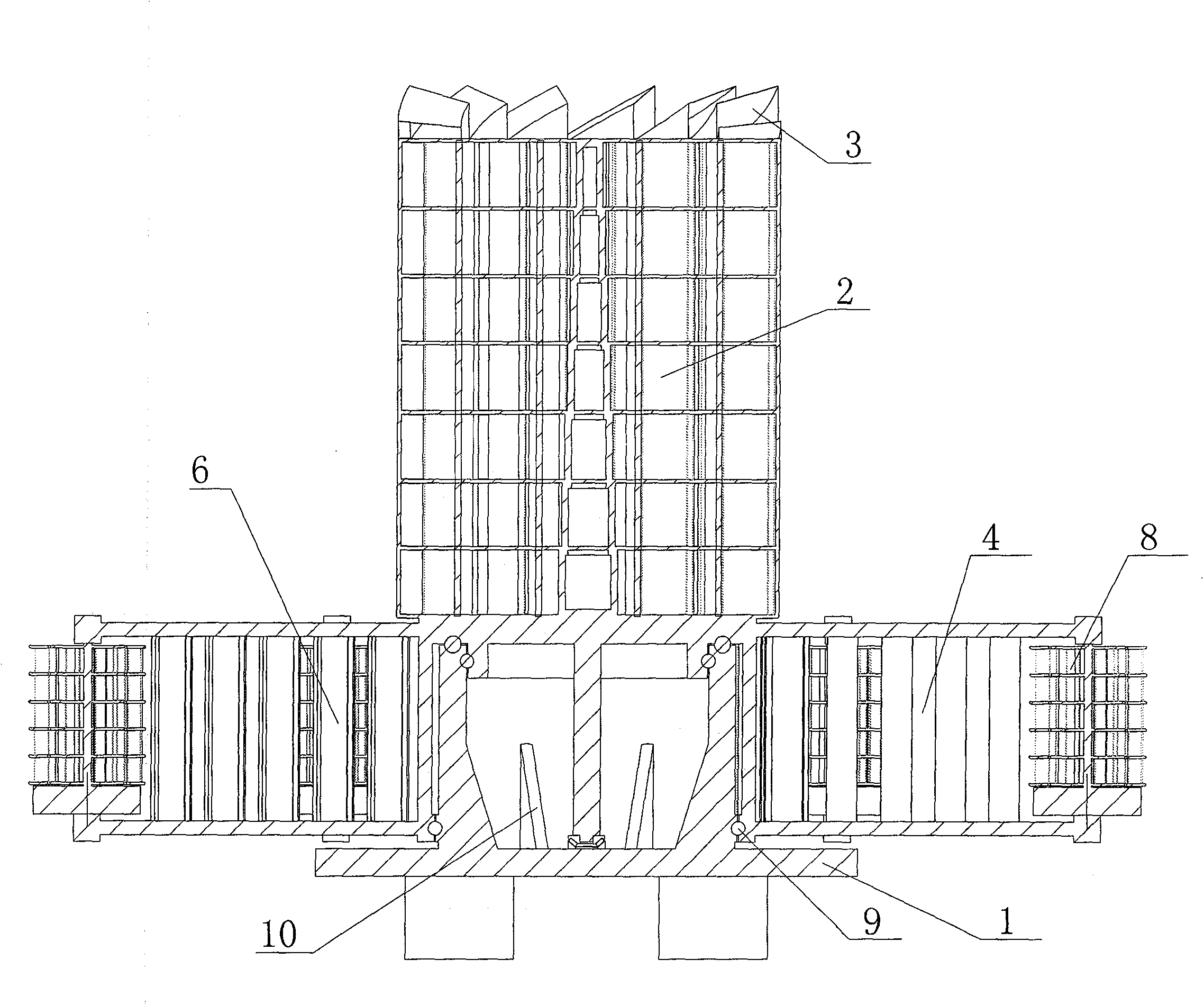

[0031] Such as Figure 1-Figure 5 As shown, the high-power vertical axis multi-wind wheel group combined wind power generation tower wheel, pouring the cement tower base 1 of the fan with a total height of 6-10 meters, the tower base 1 is divided into two modes according to the height and function of the fan:

[0032] (1) The power generation capacity is 1 MWh, the total height is 40-60 meters, the tower base 1 is integrated layout mode: the height is 15 meters, the diameter is 22 meters, and the inside is the generator room. The top of the tower base and the top of the machine room are where the rolling bearings are arranged. The cement outer wall of the machine room is where the auxiliary wind wheel guide rail is arranged.

[0033] (2) The power generation capacity is 2 MWh, the total height is 60-80 meters, and the diameter of tower foundation 1 is arranged in two sections: the upper section is 45 meters high and the diameter is 38-68 meters. The hollow is the generator r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com