Friction-free rotary air supply air flotation device

A rotary air supply, frictionless technology, applied in the directions of bearings, shafts and bearings, mechanical equipment, etc., can solve problems such as the influence of thrust bearing motion, and achieve the effect of continuous air supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

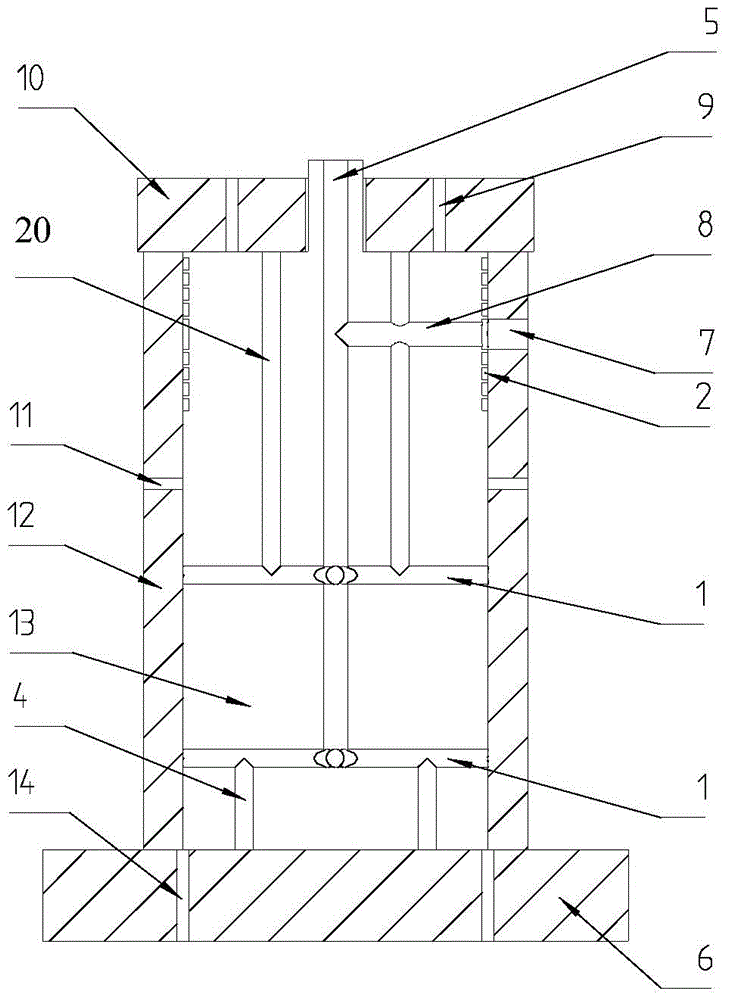

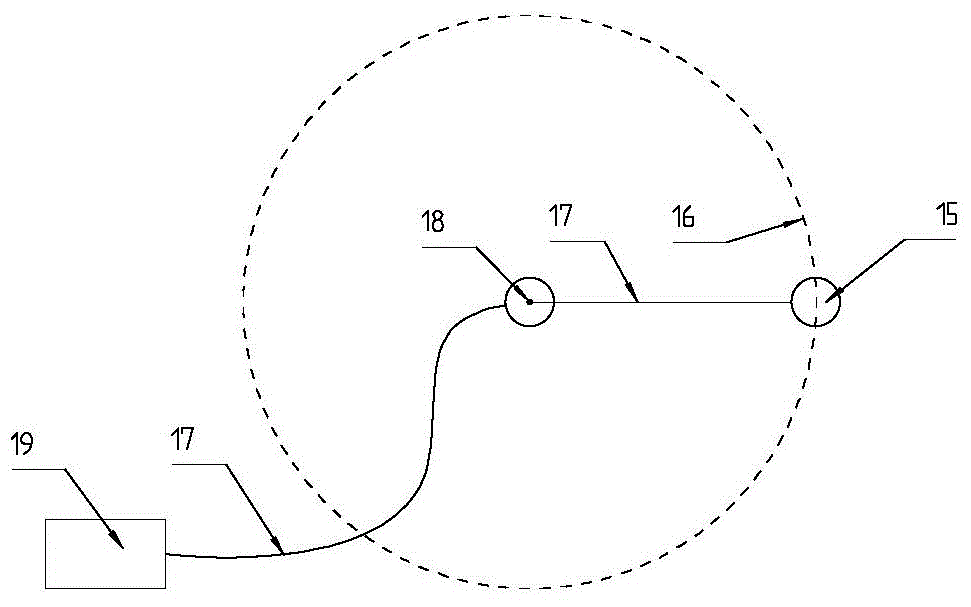

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

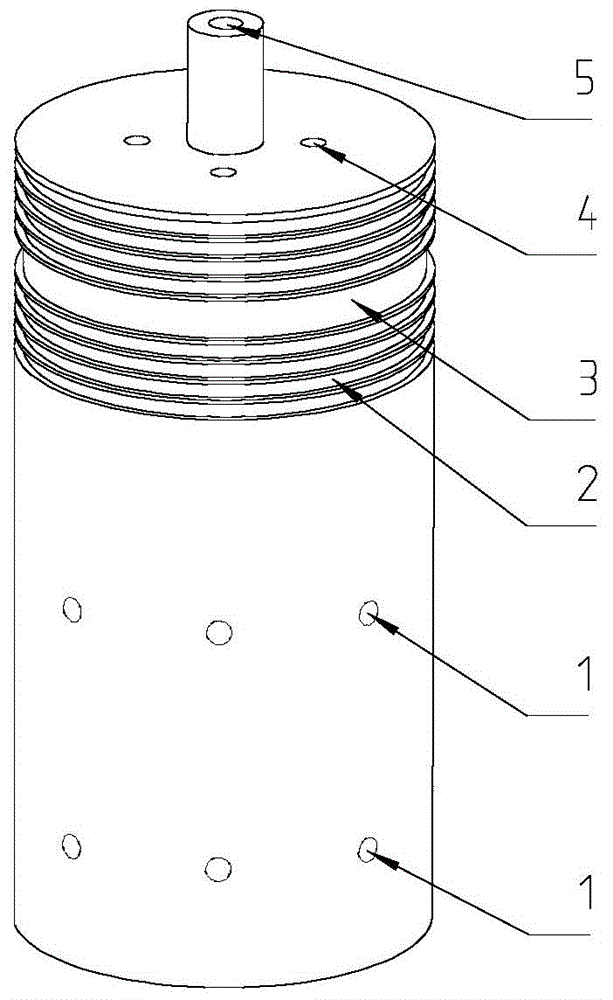

[0022] refer to Figure 1 to Figure 4 , a frictionless rotary air supply and air flotation device, comprising an inner core 13, an outer core 12 and an end cap, the inner core 13 is sleeved in the outer core 12, and the end cap includes an upper end cap 10, a lower end cap 6, the The upper and lower ends of the outer core 12 are fixed with the upper end cover 10 and the lower end cover 6 by bolts, and there are small gaps between the inner core 13 and the outer core 12 and between the inner core 13 and the upper end cover 10 and the lower end cover 6;

[0023] The upper end of the inner core 13 is provided with an annular air cavity groove 3, four annular sealing grooves 2 are opened on both sides of the annular air cavity groove 3, and the annular air cavity groove 3 is perforated in the radial direction. An air intake hole 8 is formed toward the center of the circle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com