Backlight driving circuit, backlight module and liquid crystal display device

A technology for backlight drive circuits and power modules, which is applied in static indicators, instruments, etc., can solve problems such as damage to key components, achieve circuit safety, reduce manufacturing costs, and avoid peak current effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

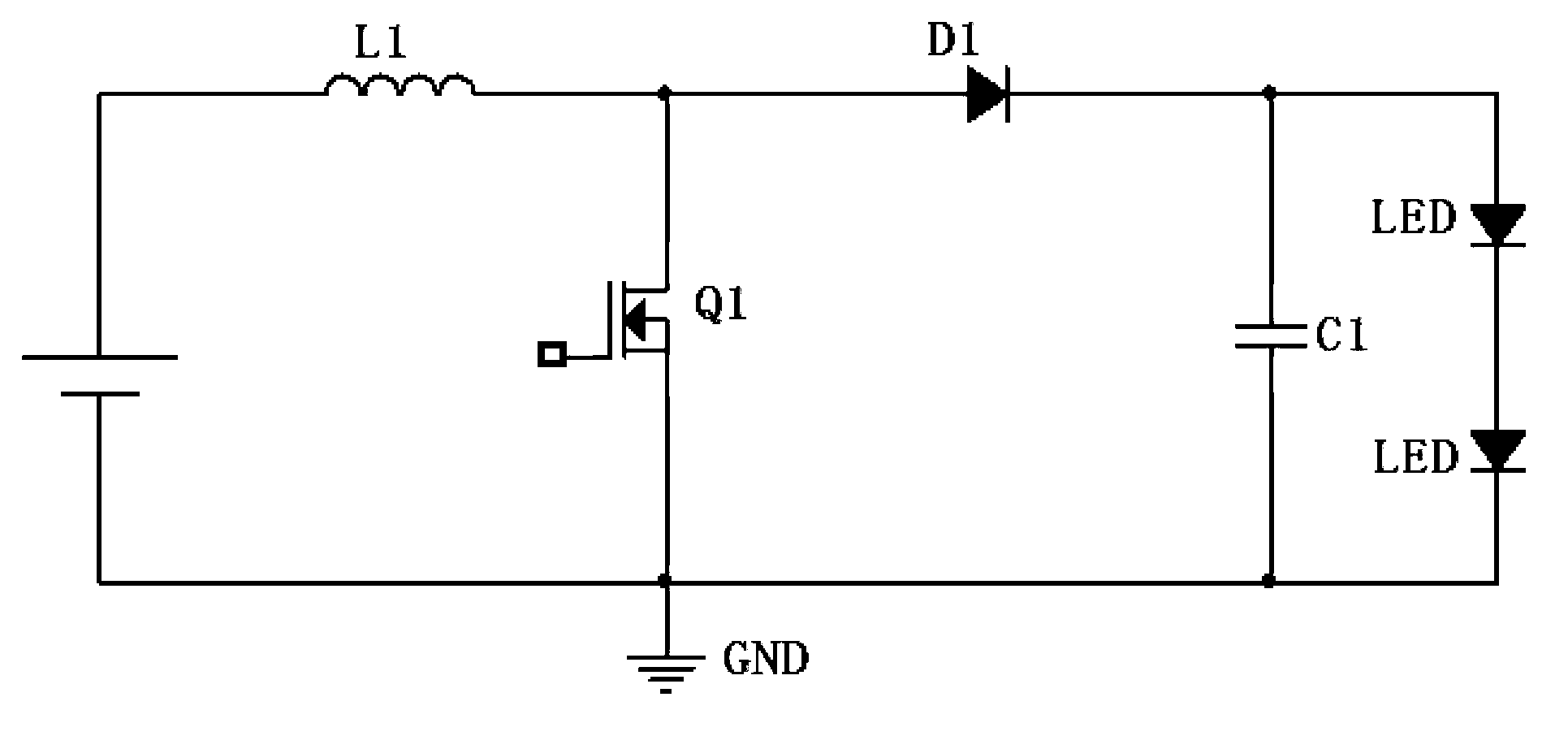

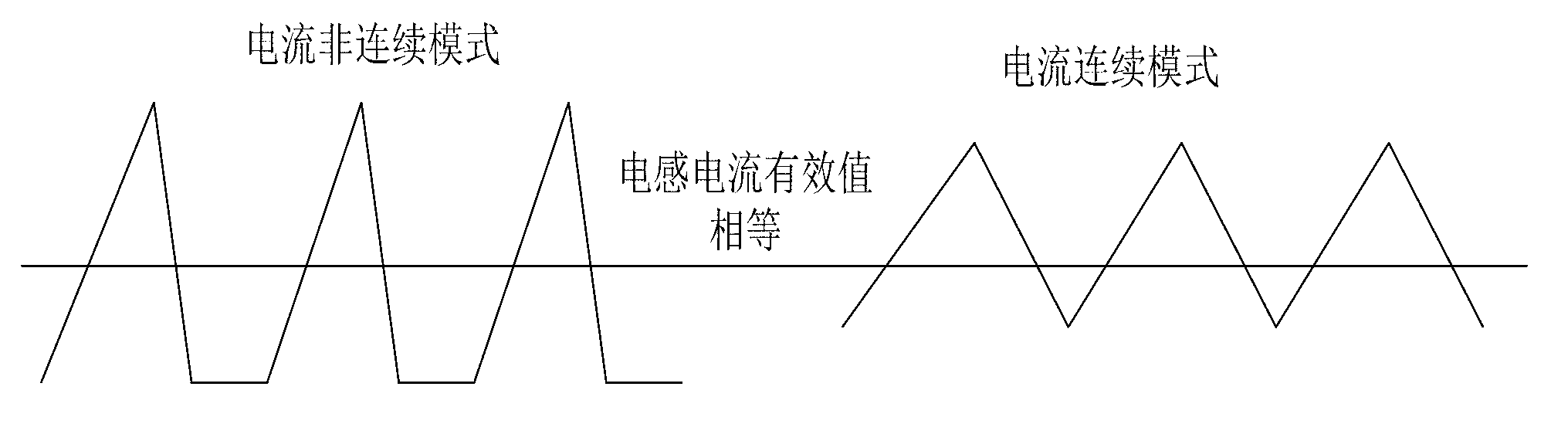

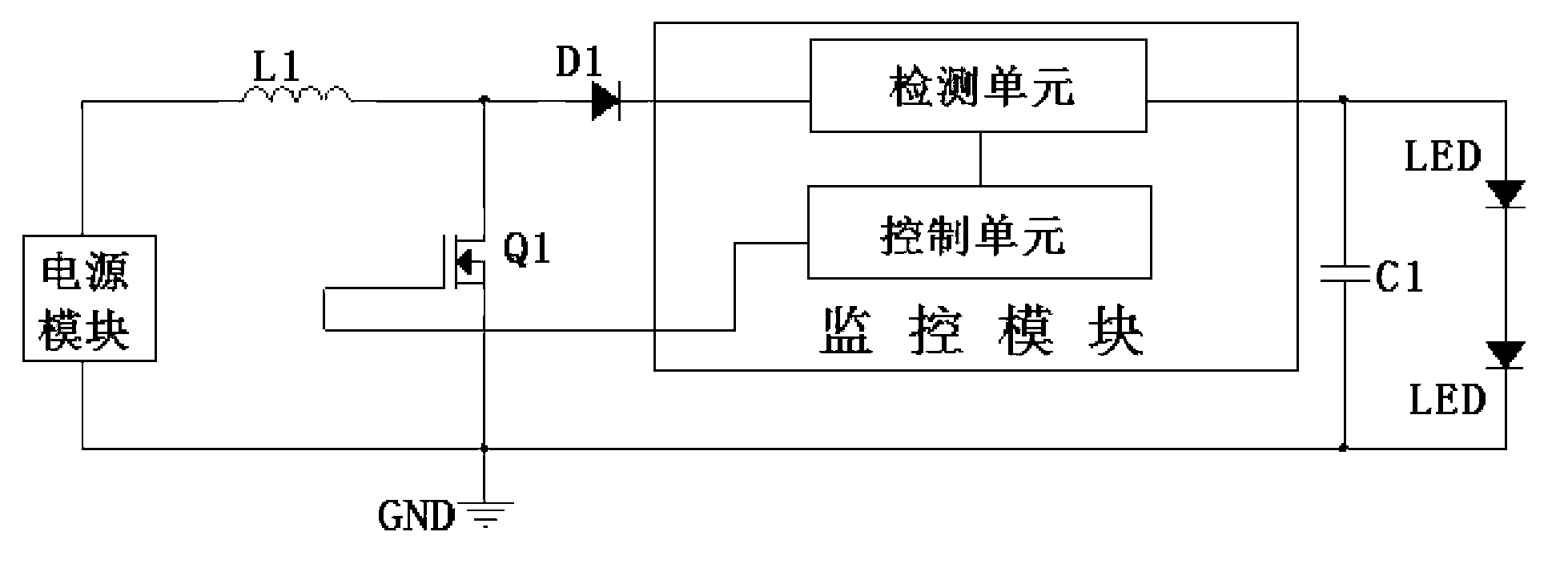

[0020] The invention discloses a liquid crystal display device. The liquid crystal display device includes a liquid crystal panel and a backlight module that provides a light source for the liquid crystal panel. The backlight module includes a backlight drive circuit, the backlight drive circuit includes a power module, an inductor connected to the output end of the power module, and an inductor connected in series LED light bar, a monitoring module for detecting the output current of the inductor is coupled between the inductor and the LED light bar, a controllable switch is connected between the output end of the inductor and the ground end of the backlight drive circuit, and the monitoring The module is coupled with a controllable switch, and when the output current of the inductor is lower than a preset value, the monitoring module controls the controllable switch to be turned on.

[0021] Since the present invention adds a monitoring module to the circuit, when the output...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com