Parameter design method for high-voltage high-capacity VSC (voltage source converter)

A voltage source converter, parameter design technology, applied in AC network to reduce harmonics/ripple, harmonic reduction devices, etc., can solve the problem of difficult to accurately realize the control target of the converter, and avoid the problem of power loss , The effect of meeting the requirements of grid-connected power quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

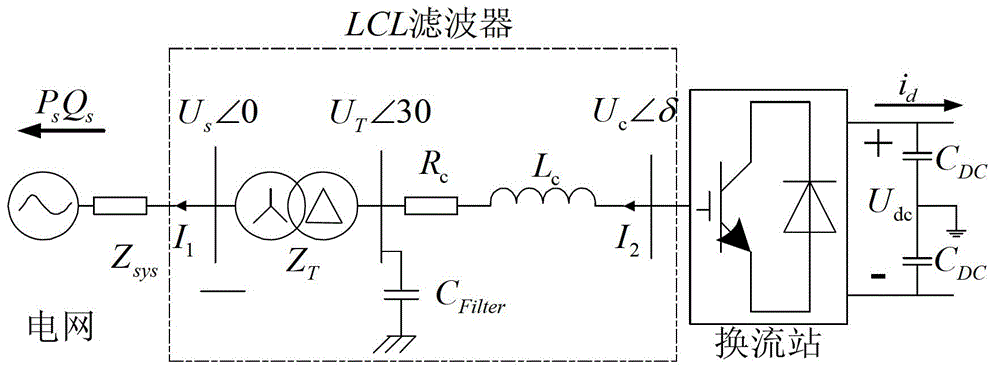

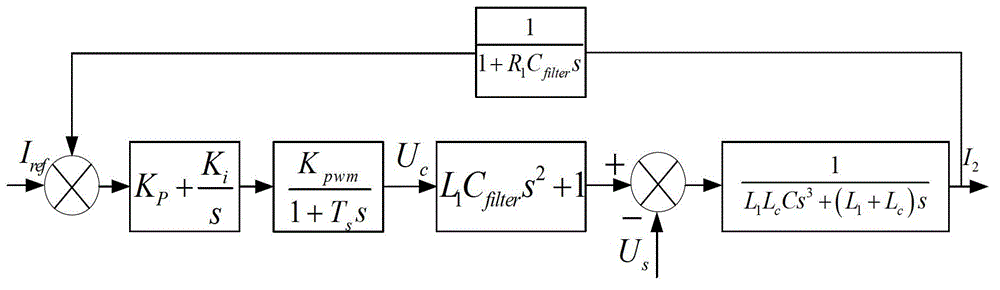

[0044] The main circuit topology of three-phase voltage source converter (VSC) using LCL filter is as follows: figure 1 As shown, the LCL filter includes a grid-side reactor, a valve-side reactor, and a filter capacitor connected in parallel between the valve-side reactor and the grid-side reactor.

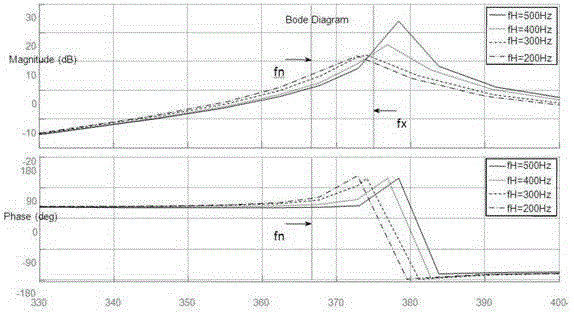

[0045] The parameters involved in the LCL filter for high-voltage and large-capacity converters include the reactance value of the valve-side reactor, the reactance value of the grid-side reactor, the short-circuit resonant frequency, the open-circuit resonant frequency and the capacitance value of the filter capacitor. Its design method is:

[0046] (1) Calculate the reactance value parameters of the valve side reactor. The inductance of the valve side reactor is obtained by using the power operating range of the voltage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com