Processing method for delaying production peak of oolong

A processing method and technology for oolong tea, which are applied in the field of processing to delay the peak period of oolong tea production, can solve the problems of increased cost, difficulty in guaranteeing quality, high labor intensity of workers, etc., and achieve quality assurance, reduction of daily labor intensity, and thick and bright leaf bottoms. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

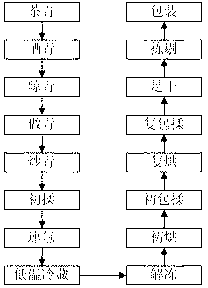

Image

Examples

Embodiment 1

[0032] A kind of processing method of delaying the production peak period of oolong tea of the present invention, its specific preparation method is as follows:

[0033] (1) Green tea: according to the 30%-50% of the daily processing capacity, the open-faced two- and three-leaf tea greens of oolong tea trees are suitable for harvesting.

[0034] (2) Sunshine: Before 11:00 am or after 3:00 pm in fine weather, spread the tea green evenly on the sun-drying cloth under weak sunlight, and spread the tea green 1.8- 2.2kg, sun exposure temperature 28-32 ℃, sun exposure time 20-50min, and within this temperature range, the drying time depends on the strength of the sun. When the sun is strong, the drying time should be short, otherwise it should be long; Mix 1-2 times during the greening process. When the surface luster of the dark green leaves disappears and becomes dark green, the top two leaves droop slightly, the smell of grass disappears, and the fragrance is slightly transpare...

Embodiment 2

[0046] A kind of processing method of delaying the production peak period of oolong tea of the present invention, its specific preparation method is as follows:

[0047] (1) Green tea: according to harvesting 40% more than the daily processing capacity, the open-faced two- and three-leaf tea greens of oolong tea trees are suitable for production.

[0048] (2) Green drying: before 11:00 am in fine weather, spread the green tea evenly on the green drying cloth under weak sunlight, spread 2kg of green tea per square meter, and the sun exposure temperature is 30°C. The sun exposure time is 40 minutes, and the drying process is stirred twice. When the surface luster of the dark green leaves disappears and becomes dark green, the top two leaves droop slightly, the smell of grass disappears, and the weight loss rate is 8%, it is moderately sun-dried;

[0049] (3) Green drying: move the moderately sun-dried tea greens into the green room, and evenly spread the tea greens in the wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com