A method of converting plc instruction list program into common petri net

A program conversion and instruction list technology, applied in the field of converting PLC instruction list programs into ordinary Petri nets, can solve problems such as high computational complexity, collision, and unverifiable states, and achieve simple logical thinking, concise excitation conditions, The effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

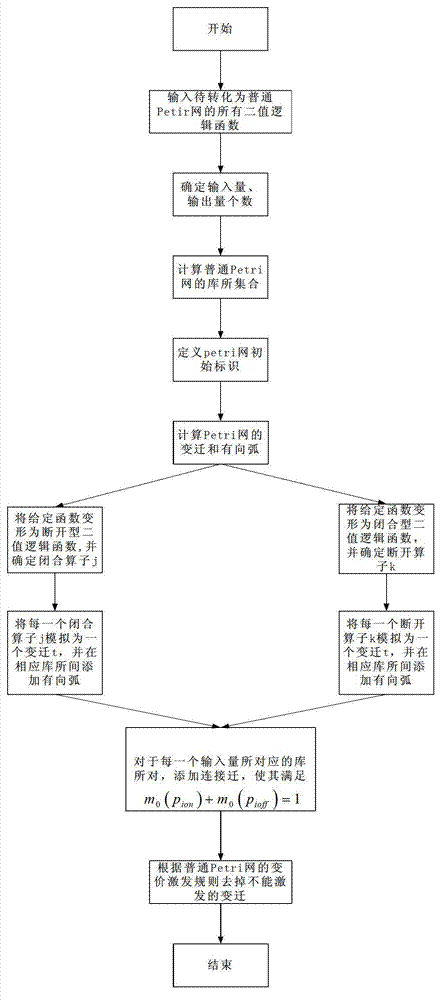

Method used

Image

Examples

Embodiment

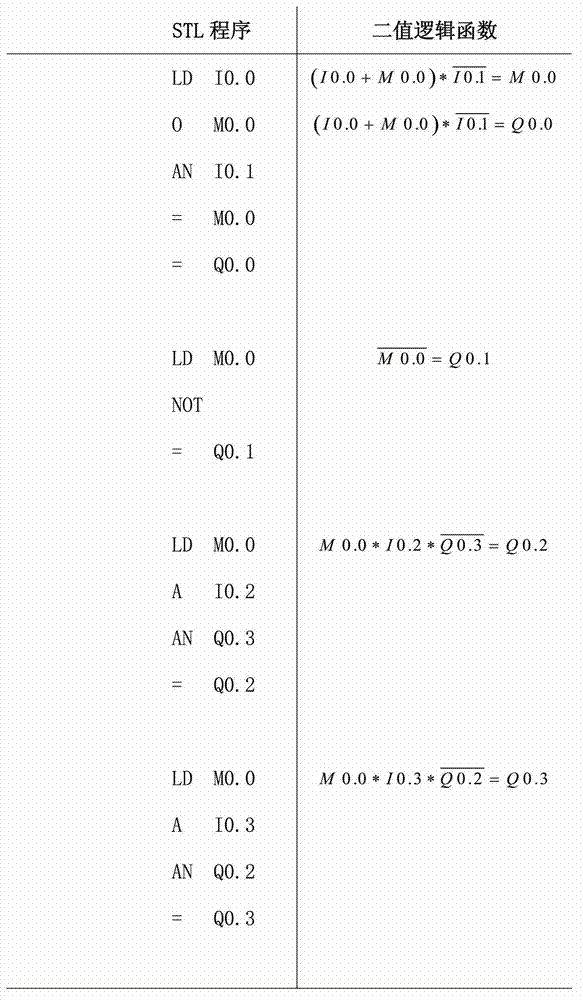

[0079] Example: Control program of two parallel moving doors

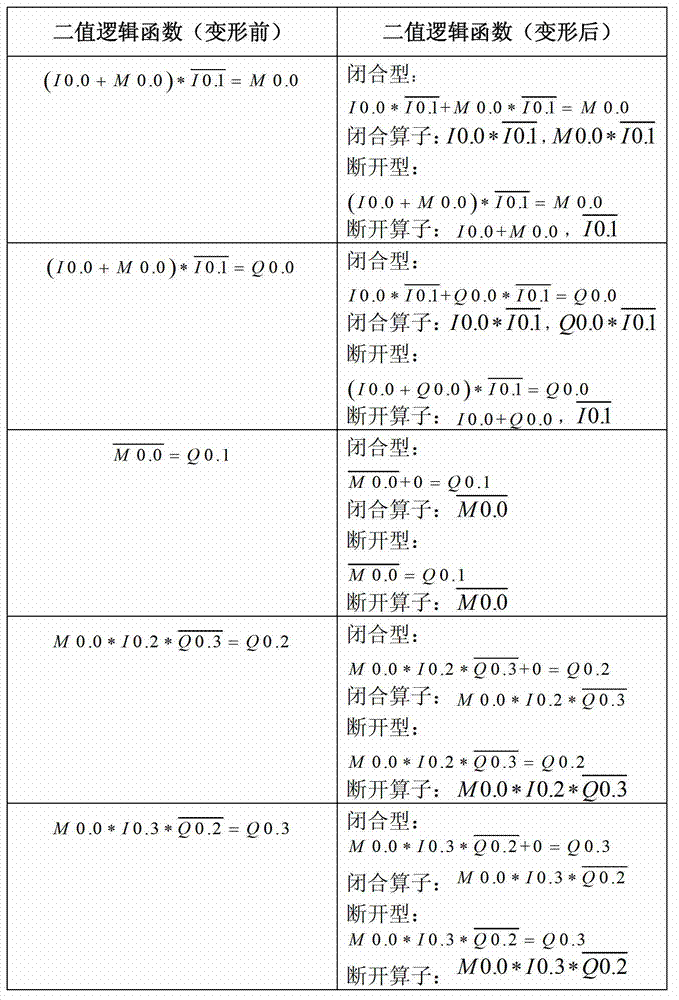

[0080] According to the control specification of the system, compile the PLC instruction list program that meets the requirements, such as figure 2 As shown, the input terminal I0.0 of the PLC is connected to the mobile door power start button, I0.1 is connected to the power off button, I0.2 is connected to the sensor switch of the mobile door 1, I0.3 is connected to the sensor switch of the mobile door 2, and the output terminal M0 .0 is connected to the system start relay, Q0.0 is connected to the power start indicator, Q0.1 is connected to the power off indicator, Q0.2 is connected to the motor that controls the switch of moving door 1, and Q0.3 is connected to the motor that controls the switch of moving door 2. When the outside presses the mobile door power start button, the mobile door system is powered on and the power start indicator light is on. When a guest is in the range covered by the mobile door 1 senso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com