Drink bottle

A beverage bottle and bottleneck technology, applied in the field of beverage bottles, can solve the problems of many parts, increase material cost and processing cost, increase assembly process and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

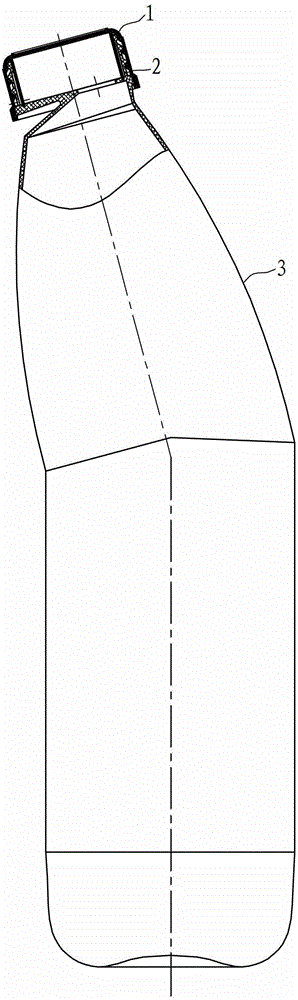

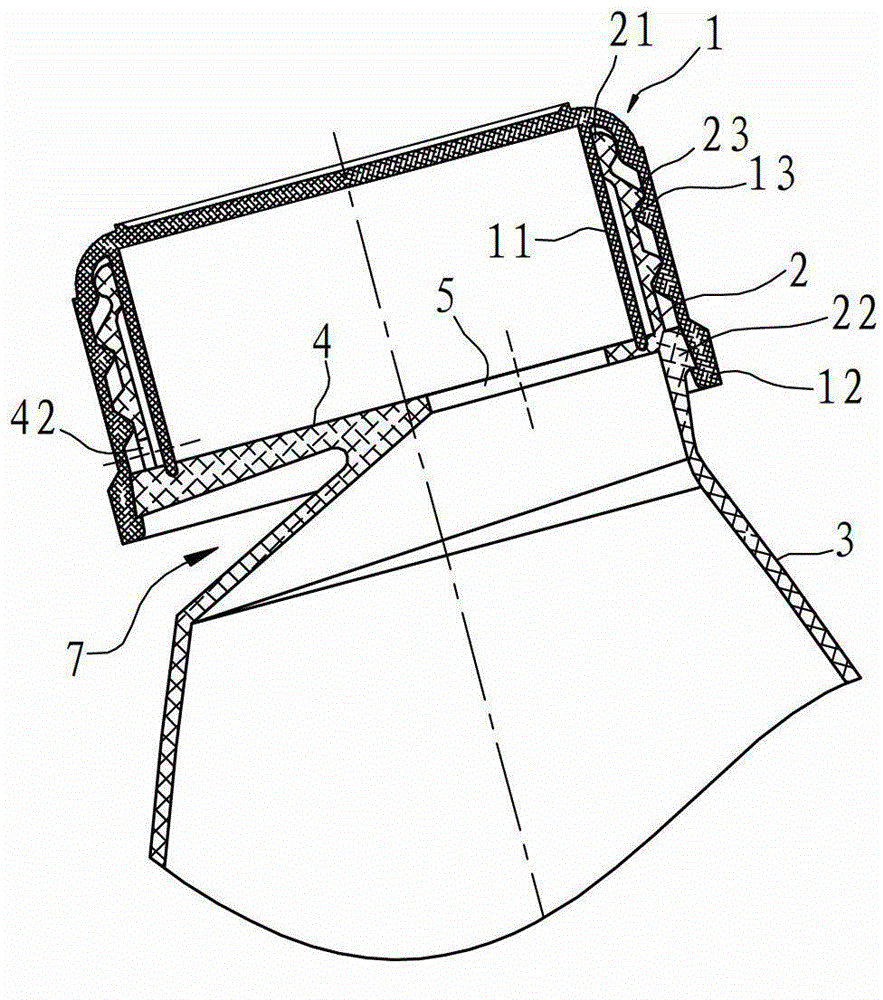

[0029] Example 1, such as Figure 1 to Figure 4 As shown, the beverage bottle in this embodiment includes a bottle body 3 and a bottle cap 1. The bottle body 3 has a bottle neck 2 arranged obliquely. Cover and cover the bottle mouth, the inside of the bottle neck 2 has a non-return plate 4 arranged obliquely, the high end of the non-return plate 4 is provided with a discharge hole 5 communicating with the bottle mouth, and one side of the bottle neck 2 has a discharge port 42 , the discharge port 42 is arranged near the lower end of the non-return plate 4 and can discharge the beverage backflowed on the non-return plate 4 . A groove 7 is formed on the outer wall at the lower end of the connection between the bottleneck 2 and the bottle body 3 , and a non-return plate 4 is formed at the upper end of the groove 7 .

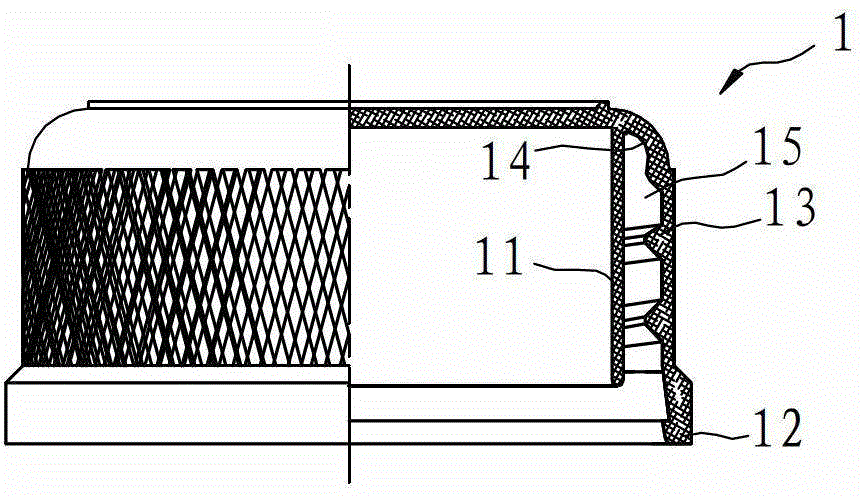

[0030] A sealing ring 11 is formed on the inner side of the bottle cap 1. Correspondingly, the upper end surface of the non-return plate 4 is formed with a sealing...

Embodiment 2

[0035] Example 2, such as Figure 5 As shown, the non-return plate 4 in this embodiment is equivalent to a partition to isolate the backflowing beverage, and no groove is provided at the connection between the neck and the bottle body, making the manufacture more convenient. Refer to Example 1 for other structures.

Embodiment 3

[0036] Example 3, such as Figure 6 As shown, the beverage bottle in this embodiment has an axially protruding baffle plate 6 on the lower edge of the discharge hole 5 in order to make the returned beverage collect on the non-return plate as much as possible. Refer to Example 1 for other structures.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com