Milled soap forming device

A molding device and soap technology, applied in the direction of molding soap, etc., can solve the problems of waste of resources, pollution, etc., and achieve the effect of saving and reducing pollution

Inactive Publication Date: 2013-05-29

XIANGYANG HIGH TECH DEV ZONE SHENGLI ELECTRONICS TECH BUSINESS DEPT

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] When the soap is used to the point that it cannot be used in small pieces, it is generally thrown away as waste, which not only causes a waste of resources, but also produces certain pollution

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

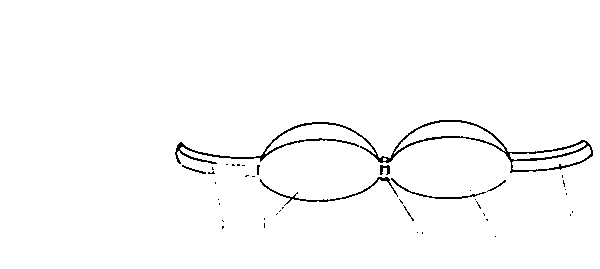

[0008] As shown in the embodiment of the accompanying drawings: two semi-circular boxes 1 that match in size are connected together by a hinge 2 , and a handle 3 is connected to the outside of the semi-circular boxes 1 .

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides a milled soap forming device. Two semicircular case bodies which are fitted with each other in size and opposite to each other are connected together by a hinge; and a handle is connected to the outer side of each of the semicircular case bodies. During a using process, the milled soap blocks can be placed to the semicircular case bodies, and the two semicircular case bodies are folded and extruded by the handles, i.e. the milled soap blocks are extruded into an integrated soap block for re-use, thereby saving the resources and reducing the pollution caused by wastes.

Description

technical field [0001] The invention relates to a soap forming machine, in particular to a crushed soap forming device. Background technique [0002] When the soap is used to the point that it cannot be used in small pieces, it is generally thrown away as waste, which not only causes a waste of resources, but also produces certain pollution. Contents of the invention [0003] The invention provides a broken soap forming device, which can squeeze broken small soap pieces into whole pieces for reuse. [0004] The invention includes a hinge, and the adopted technical scheme is: two semicircular boxes with matching sizes are connected together through a hinge, and a handle is connected to the outside of the semicircular boxes. [0005] The beneficial effects of the present invention are: the broken soap pieces can be put into the semicircular box, and the two semicircular boxes can be closed and squeezed through the handle, so that the broken soap can be squeezed into...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C11D13/18

Inventor 赵峰

Owner XIANGYANG HIGH TECH DEV ZONE SHENGLI ELECTRONICS TECH BUSINESS DEPT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com