A side-suction and upper-discharge range hood

A range hood and oil fume technology, which is applied in the direction of oil fume removal, heating methods, household heating, etc., can solve the problems of low smoking efficiency of volute components, low efficiency of oil fume suction and exhaust, poor grease filtering effect, etc., to improve the work effect and service life, good filtering effect, and high oil fume inhalation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below with reference to the accompanying drawings.

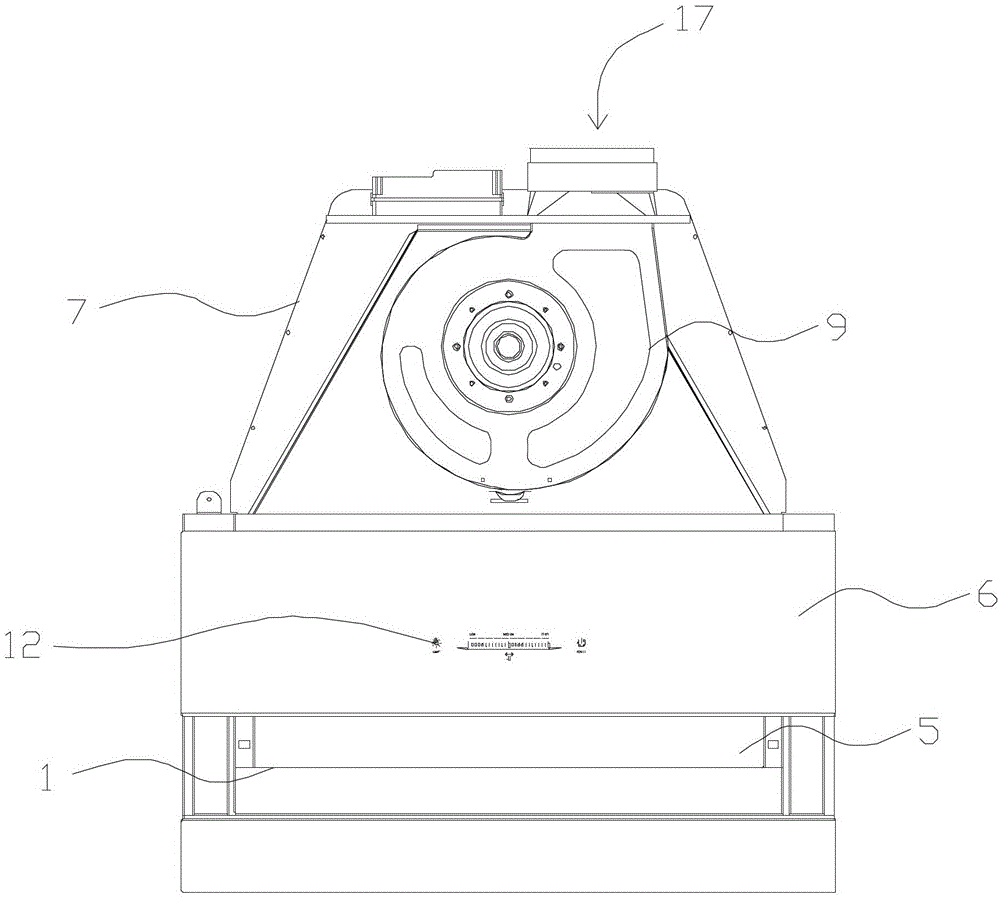

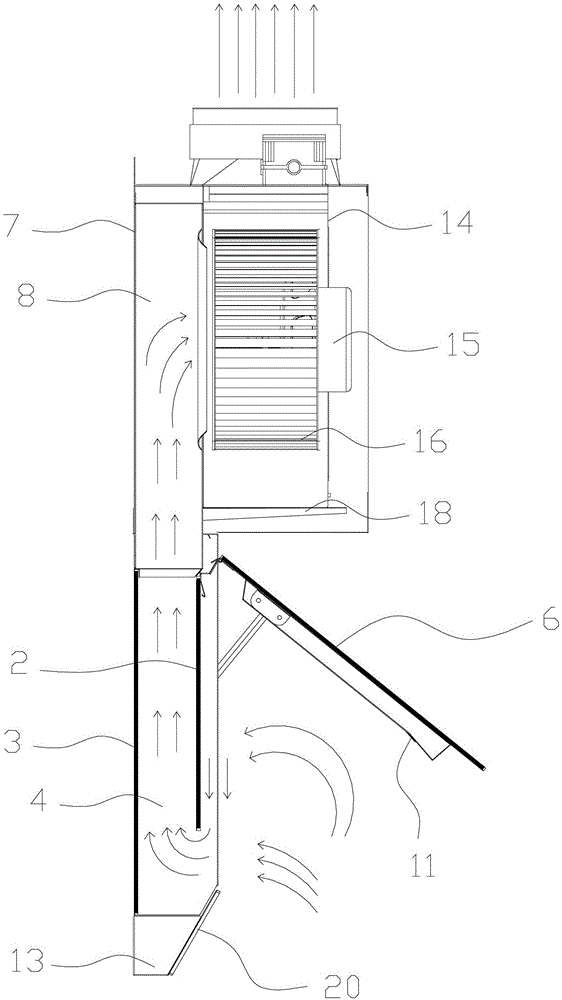

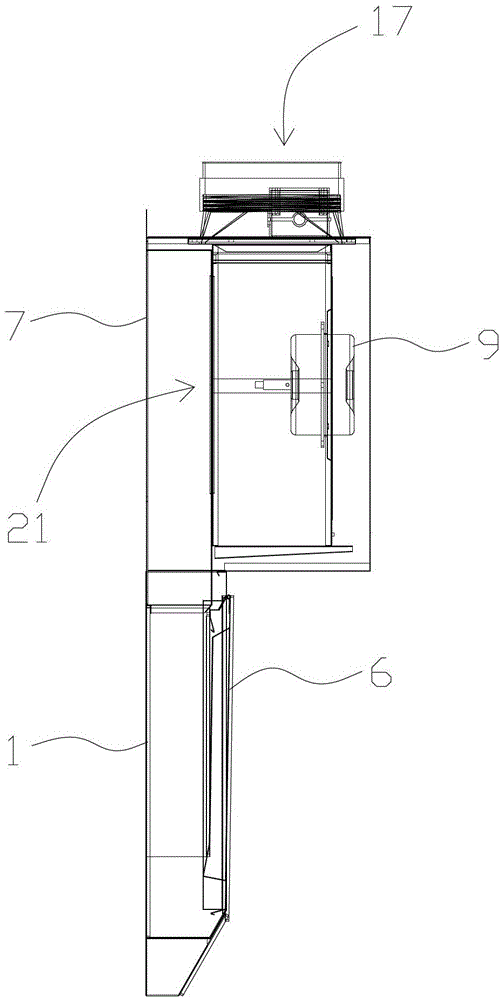

[0023] Such as Figure 1-Figure 4 As shown, a side-suction and upper-discharge range hood described in this embodiment includes a flat straight smoke inlet box 1 and a fan assembly 9. The smoke inlet box 1 includes a front panel 2 and a rear panel 3 and the smoke inlet There is a vertical smoke inlet chamber 4 inside the box 1. The smoke inlet chamber 4 is located between the front board 2 and the rear board 3 and opens upward. The lower end of the front board 2 has a smoke inlet chamber connected to the smoke chamber. 5, the outer side of the front plate 2 is provided with a rotating panel 6 that can open or close the smoke inlet 5, and a smoke collection box 7 is provided above the smoke inlet box 1, and the inside of the smoke collection box 7 is There is a smoke collecting chamber 8 connected with the upper mouth of the smoke inlet chamber, and the fan assembly 9 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com