Protection method for preventing frequency conversion compressor from demagnetization

A variable frequency compressor, compressor technology, applied in emergency protection circuit devices, electrical components and other directions, can solve the problems of reduced reliability, poor versatility, etc., and achieve the effects of long service life, simple and reasonable structure, and expanded operating range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

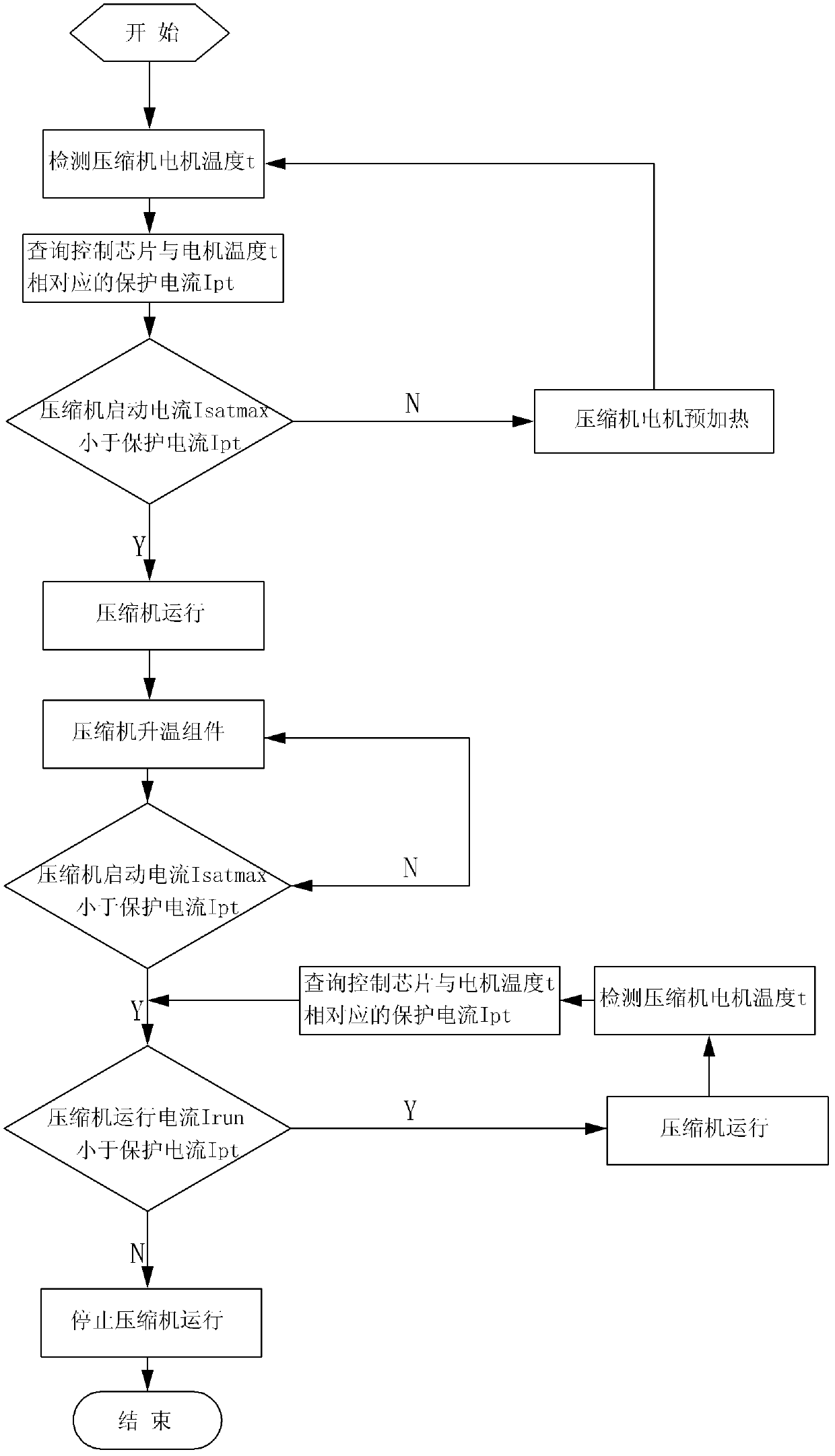

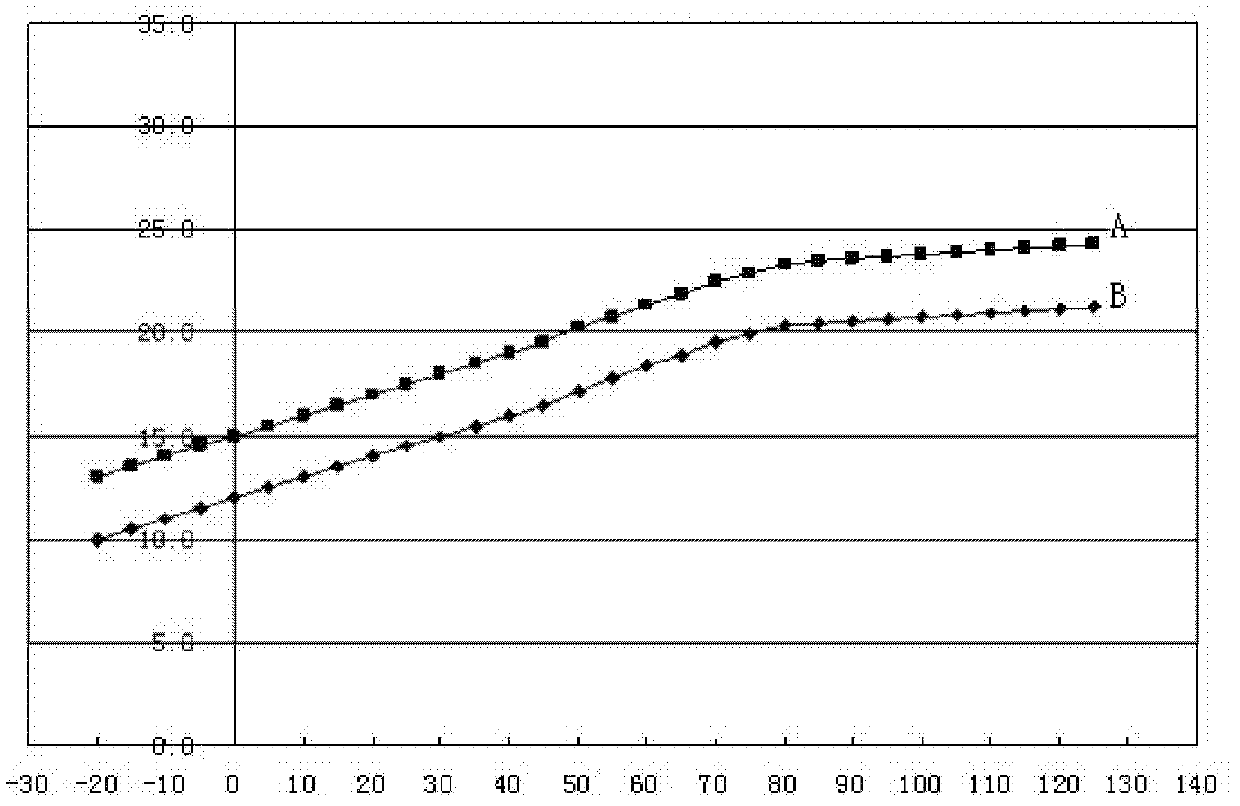

[0030] see Figure 1-Figure 4 The protection method for preventing the demagnetization of the frequency conversion compressor includes a control chip arranged on the frequency conversion compressor, and the compressor is a ferrite frequency conversion compressor. The control chip detects the motor temperature t of the compressor, and the control chip is provided with a protection current Ipt corresponding to the motor temperature t. Usually the protection current Ipt should take into account the lowest demagnetization current, but if the value is too small, it will affect the maximum cooling capacity. However, if the value is too large, the anti-magnet function of the inverter compressor cannot be realized. For ferrite variable frequency compressors, the current protection setting value is lower than the demagnetization current value at -20°C, but the general operating temperature of variable frequency compressors is 30-110°C, and the demagnetization current of ferrite magnet...

no. 2 example

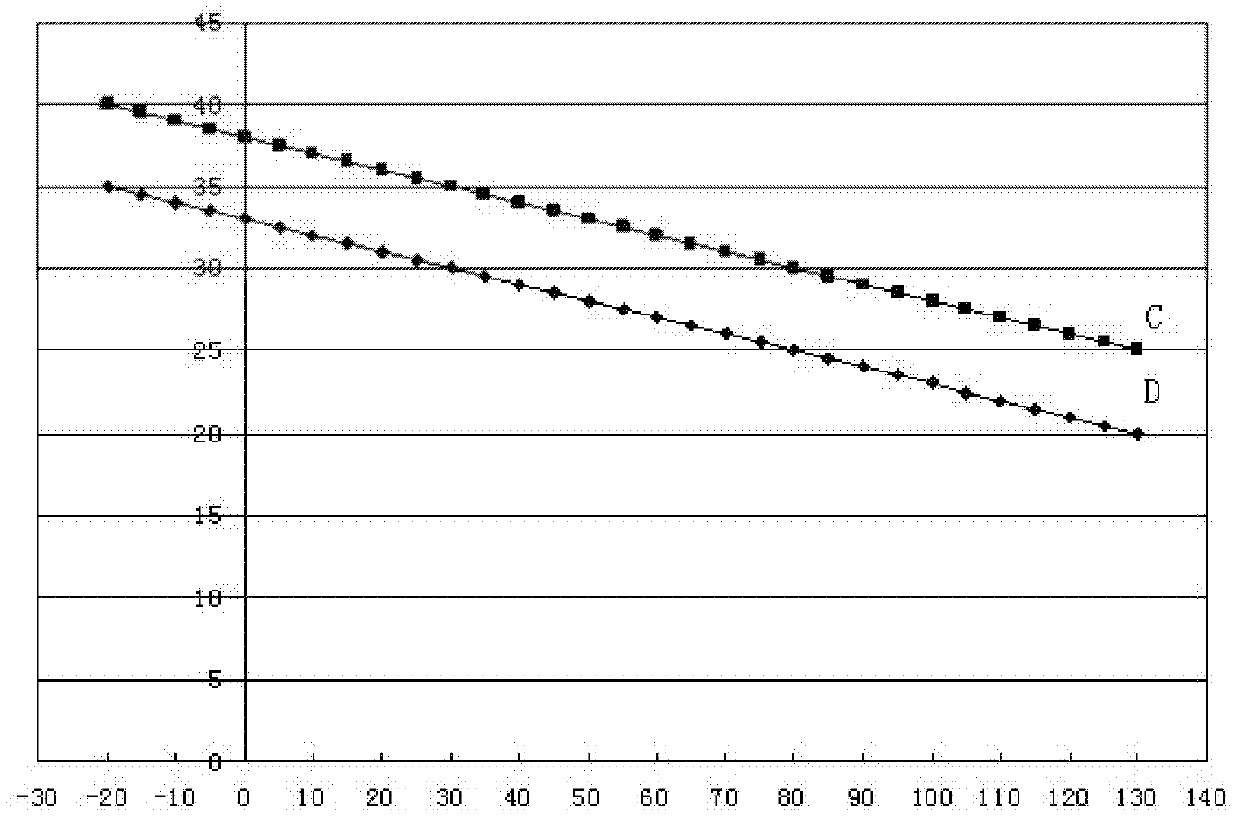

[0038] see Figure 5 , the compressor is a rare earth frequency conversion compressor, and the protection method for preventing the demagnetization of the rare earth frequency conversion compressor comprises the following steps:

[0039] 1) During the start-up phase of the compressor, query the protection current Ipt corresponding to the control chip and the motor temperature t, and judge whether the maximum start-up current Isatmax of the compressor is less than the protection current Ipt. If the maximum start-up current Isatmax of the compressor is greater than the protection current Ipt, the control chip detects in real time Compressor motor temperature t. If the maximum starting current Isatmax of the compressor is less than the protection current Ipt, the compressor will run.

[0040] 2) During the compressor operation stage, the protection current Ipt is compared with the compressor operation current Irun. If the compressor operation current Irun≤protection current Ipt,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com