Integrated ignition system

A technology of ignition rod and start-up burner, which is applied in the petroleum industry and the manufacture of combustible gas, etc., can solve the problems of frequent accidents, achieve the effect of improving operation economy, driving safety and success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

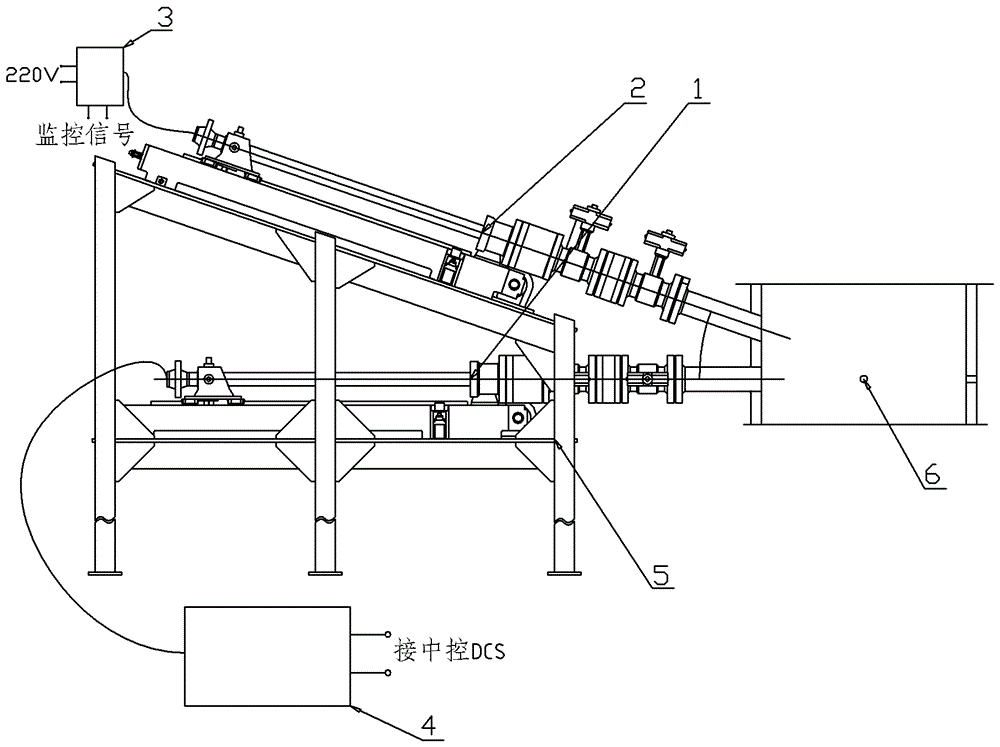

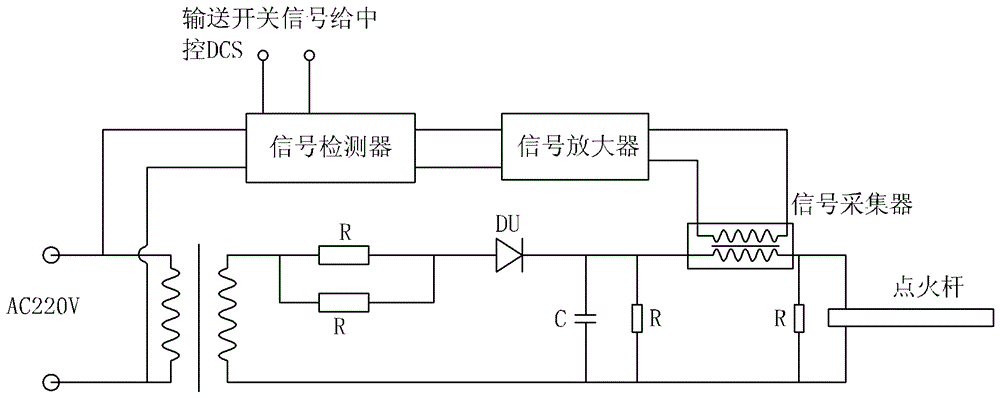

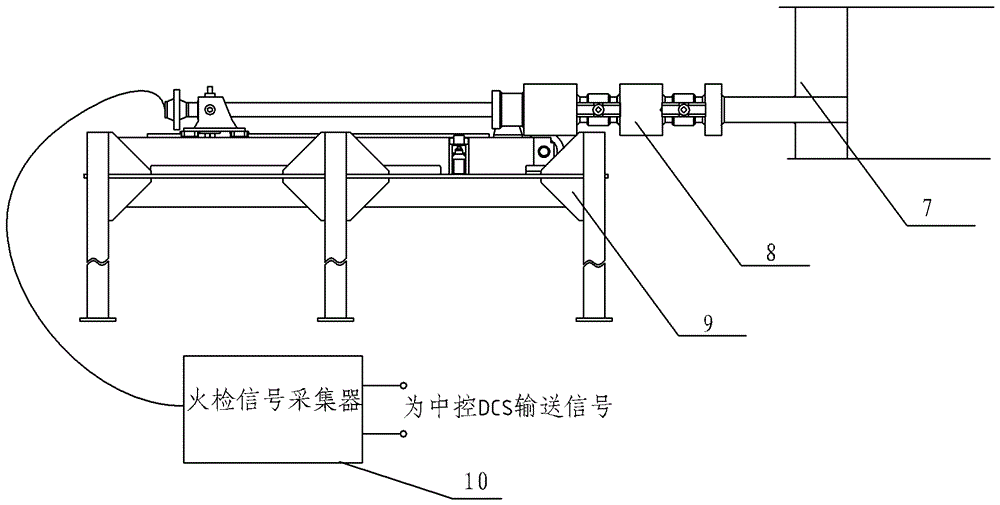

[0023] The integrated ignition and start-up system of the present invention includes a bracket, a propulsion mechanism 9, an integrated start-up burner 2, an electronic ignition device 3, a plug-in monitoring device 1 and an interlocking control device 4; the propulsion mechanism 9 is fixed on the gasifier through its own bracket The furnace body is connected with the channel provided by the gasification furnace; the integrated start-up burner 2 is fixed on the guide rail of the propulsion mechanism 9 through the fastening device; the electronic ignition device 3 includes an ignition device arranged on the integrated start-up burner 2 The rod and the electronic ignition monitoring device used to monitor the working condition of the ignition rod at the start of the burner head; the plug-in monitoring device 1 is fixed on the guide rail of the propulsion mechanism 9 by the fastening device, which is used to monitor the combustion condition of the furnace 7; interlocking The contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com