Base structure of injection pump

A syringe pump and base technology, applied in the field of syringe pumps, can solve the problems of inability to carry out continuous sampling, complex structure of the driving part of the syringe pump, poor reliability, etc., and achieve the effect of simple structure, reliable performance and accurate transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

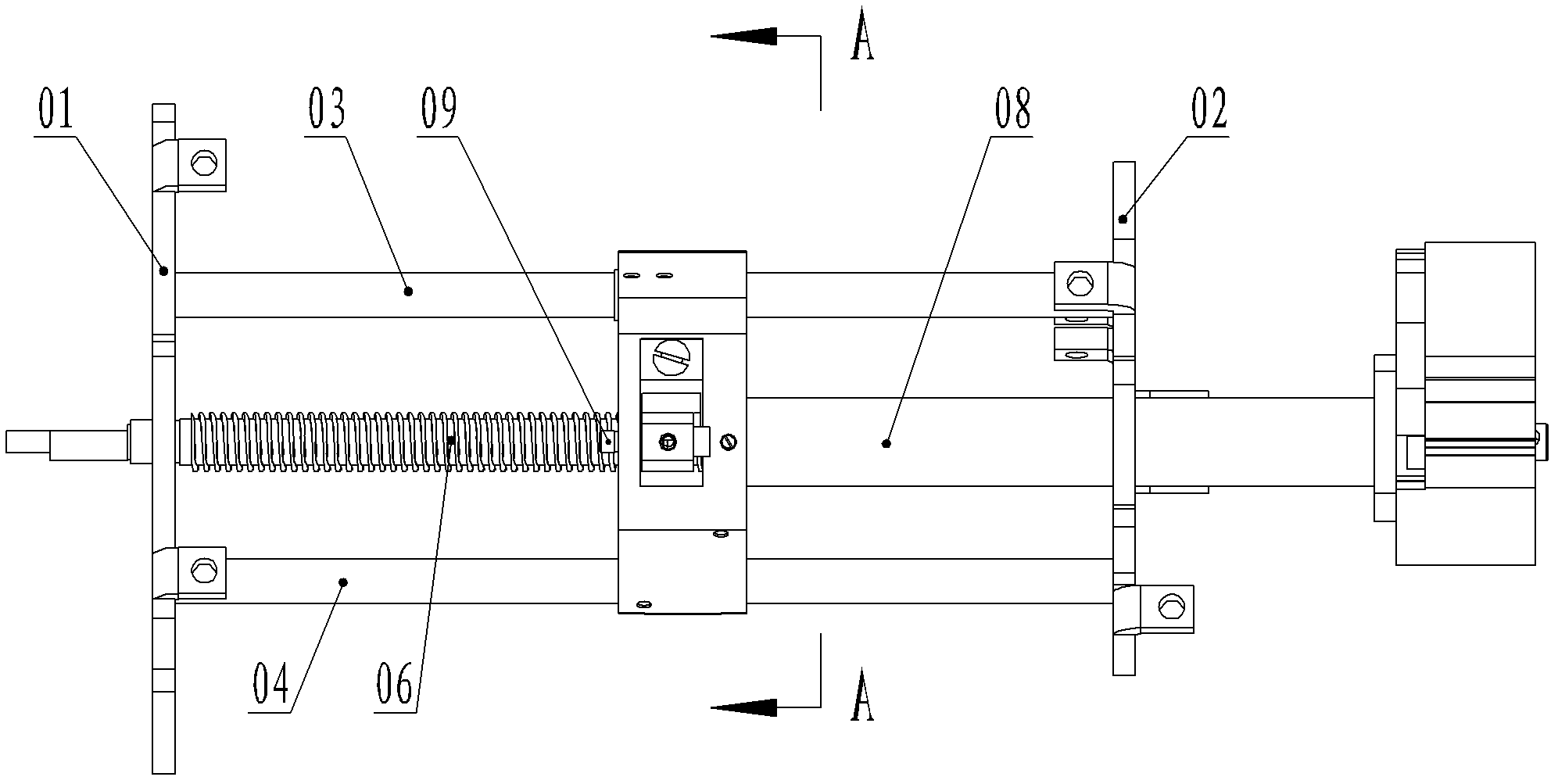

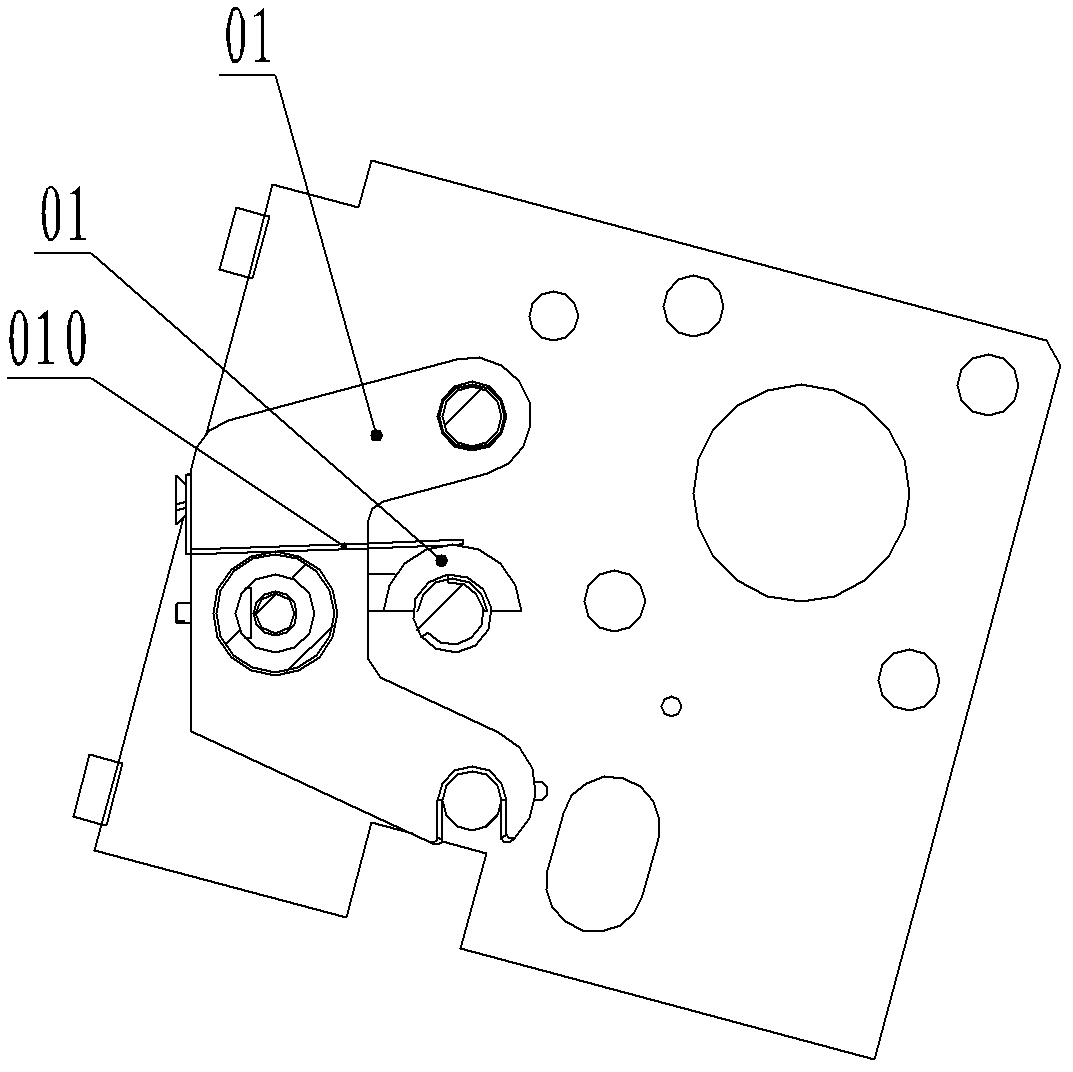

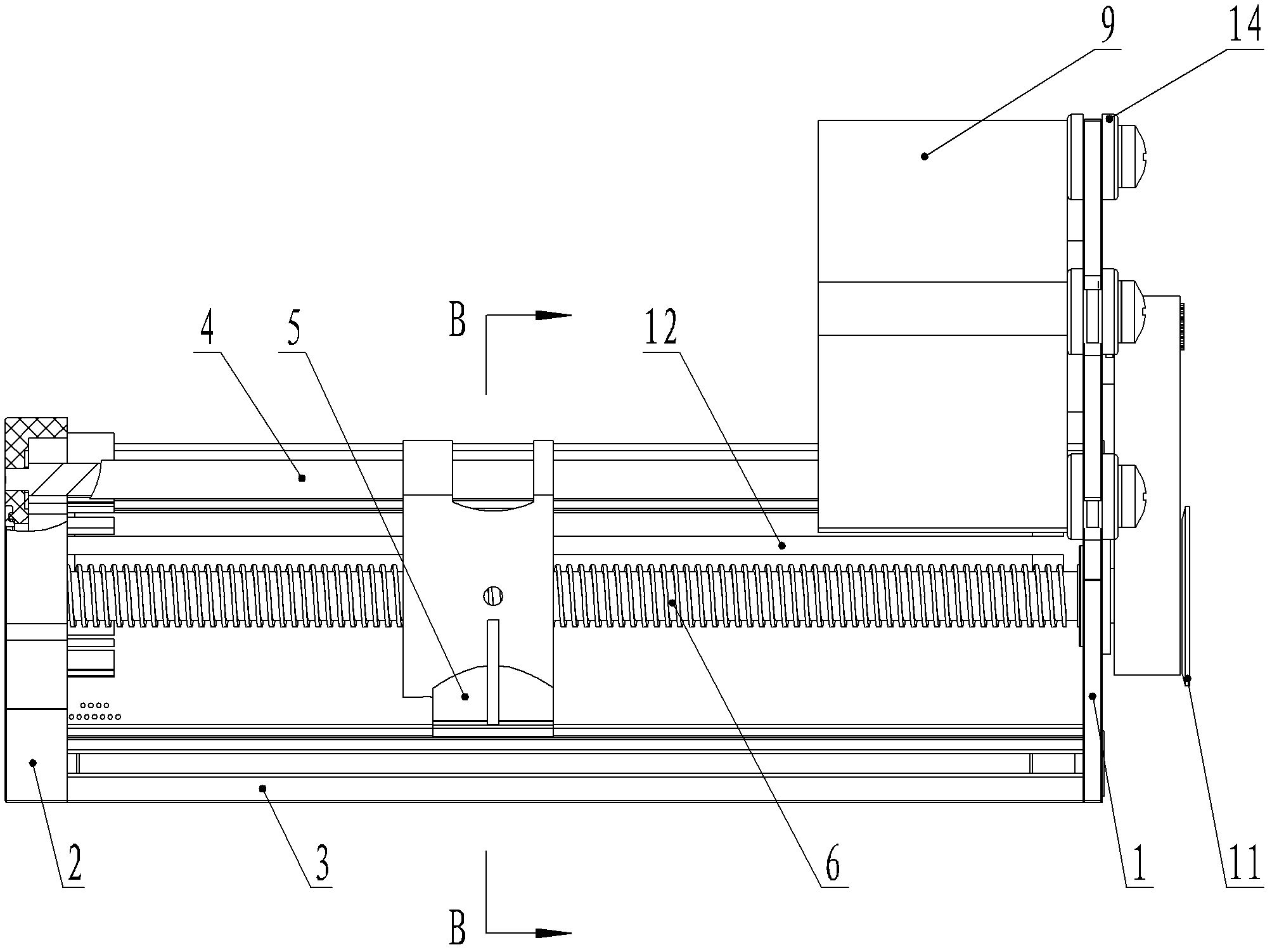

[0023] Such as Figure 3-5 As shown, the base structure of the injection pump in this embodiment includes a front mounting plate 1, a rear mounting plate 2, an aluminum profile 3, a guide rail 4, a cage 5, a lead screw 6, a spring 7, a nut 8, and a stepping motor 9 , a small synchronous pulley 10, a large synchronous pulley 11, a linear displacement sensor plate 12 and a brush 13, the front mounting plate 1 and the rear mounting plate 2 are installed on the two ends of the aluminum profile 3 respectively, and the two ends of the guide rail 4 They are arranged on the front mounting plate 1 and the rear mounting plate 2 respectively, the upper part of the cage 5 is passed through the guide rail 4 between the front mounting plate 1 and the rear mounting plate 2, and the lower part slides with the horizontal groove of the aluminum profile 3 Cooperate, the middle part is provided with a lead screw 6, the middle and lower part is provided with a screw nut mounting hole and installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com