Multifunctional guy production clamp

A multi-functional, wire-drawing technology, applied in pliers, manufacturing tools, overhead line/cable equipment, etc., can solve problems such as wire-drawing efficiency, low quality, and non-fitting of steel strands and tongues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. It should be understood that the preferred embodiments are only for illustrating the present invention, but not for limiting the protection scope of the present invention.

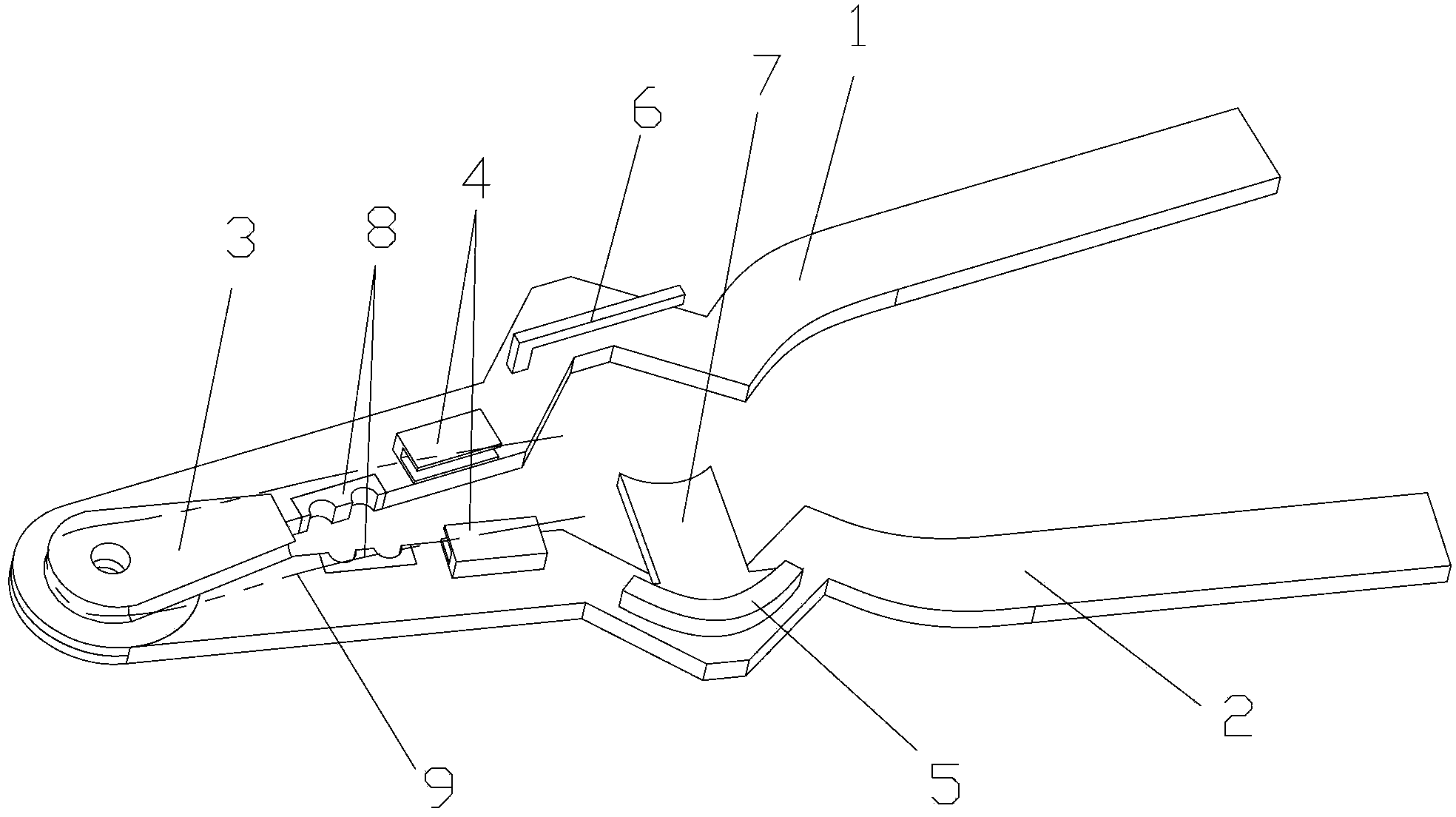

[0016] As shown in the figure, a multifunctional pull wire making pliers includes an upper handle 1 and a lower handle 2, one end of the upper handle and the lower handle is hinged together, and the connecting end of the upper handle and the lower handle is provided with a circular arc The backguy bending die 3 at the end, the arc end of the backguy bending mold is provided with an annular backguy limit groove along the arc surface, and the upper and lower handles are also provided with a pressing block 4 for fixing the position of the backguy. The upper and lower handles are also equipped with UT clamp installation fixtures.

[0017] In this embodiment, use the wire ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com