Lateral junction assembly

A joint component and transverse technology, which is applied in the direction of wellbore/well components, production fluid, construction, etc., can solve the problems of equipment leakage, limited use, difficult control of precision, etc., and achieve the effect of liquid-tight transverse joint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

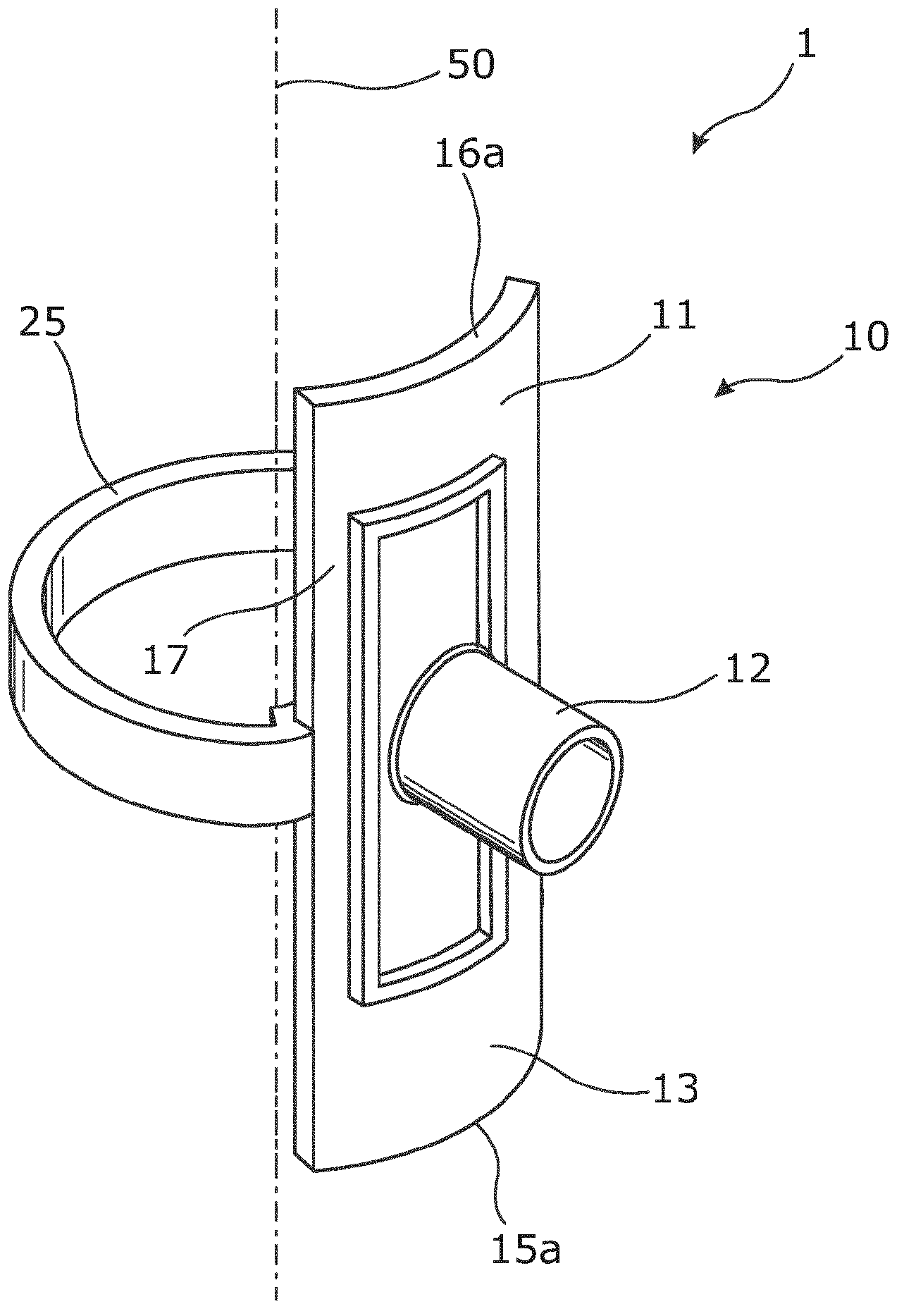

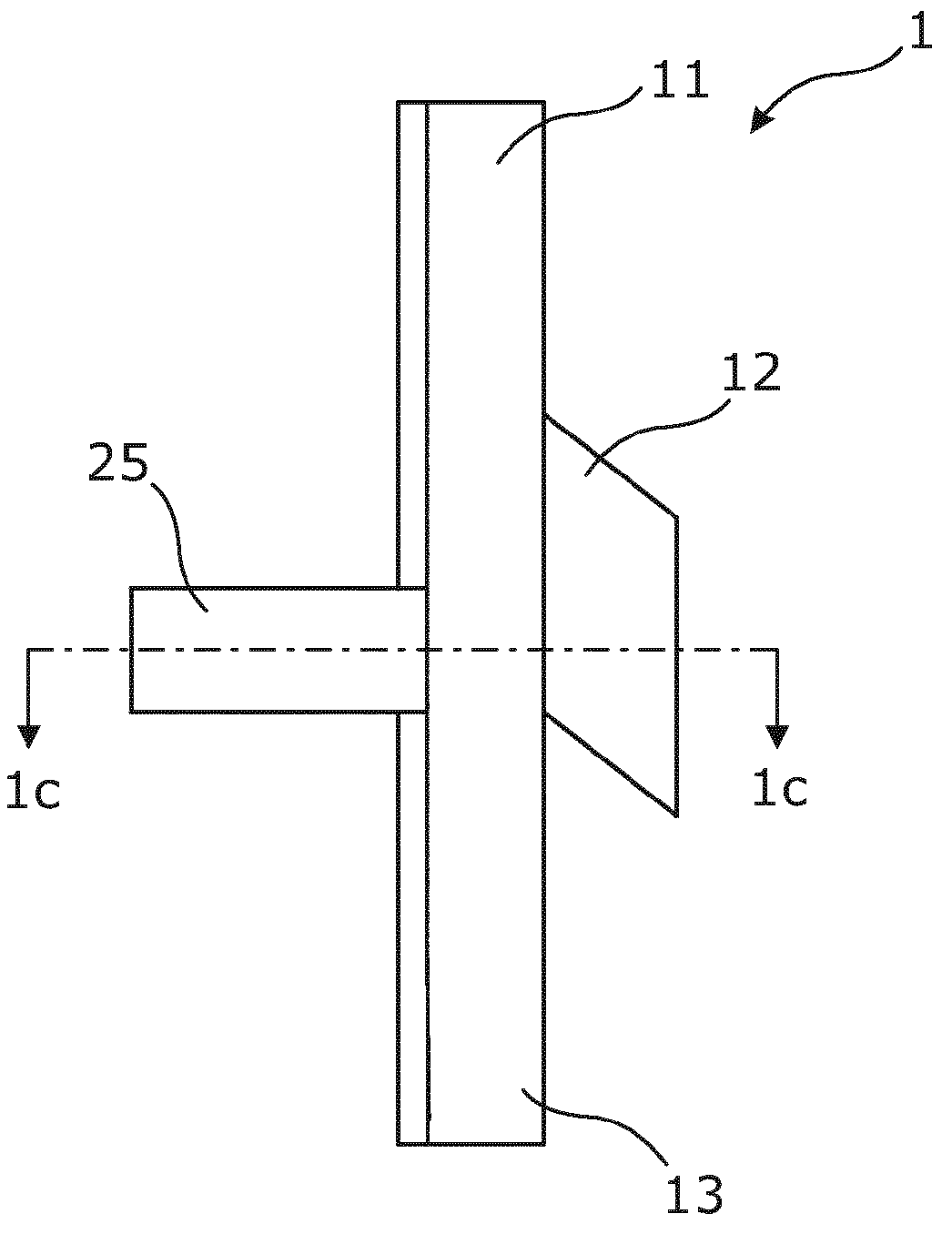

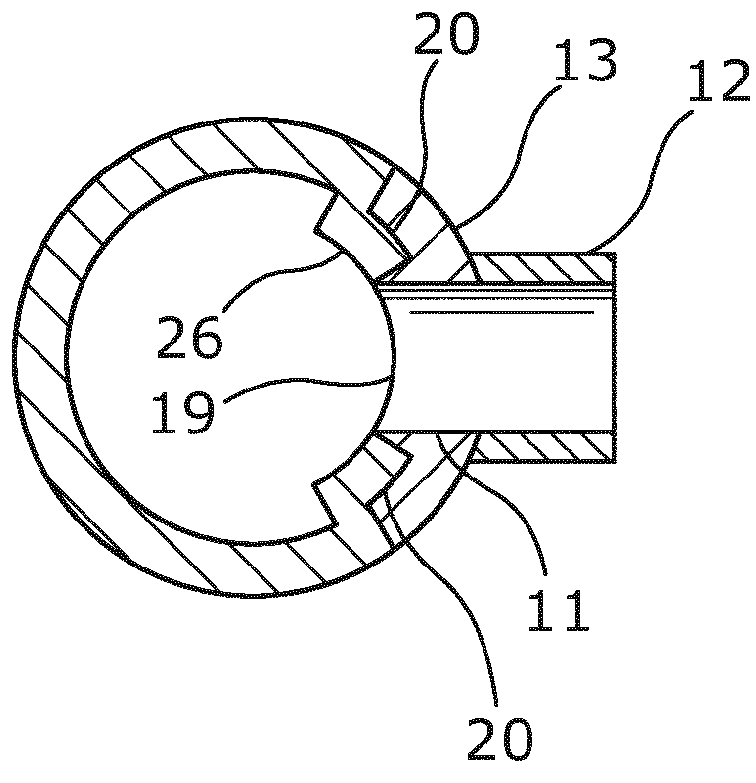

[0089] Figure 1a Shown is a transverse joint assembly 1 comprising a pipe module 10 and a fixing element 25 for fixing the pipe module 10 at a predetermined position in a casing 60 so as to Figure 6a A lateral extension is shown extending from casing 60 into the formation. The transverse joint assembly 1 extends in a longitudinal direction 50 and has a top end 16a and a bottom end 15a.

[0090] The tube module 10 has a flange 11 extending in the longitudinal direction from a bottom edge 15a to a top edge 16a. The flange is curved in a direction transverse to the longitudinal direction 50 . The tube section 12 extends from an outer surface 13 of the flange 11 on which is positioned a sealing material 14 extending around the tube section 12 . The sealing material 14 has a strip-like shape, but it will be apparent to those skilled in the art that the sealing material can be shaped and positioned in a variety of ways. The pipe module also includes a channel 18 extending from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com