Decklid hinge counterbalance assembly having a straight end torque rod with infinite rotational adjustment

A hinge assembly, torque rod technology, used in pinned hinges, wing parts, door/window accessories, etc., to eliminate bending stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Those of ordinary skill in the art will understand that terms such as "above", "below", "upper", "lower", "top", "bottom", etc. are used to describe the drawings and do not limit the scope of the present invention in any way , the scope of the invention is defined by the appended claims.

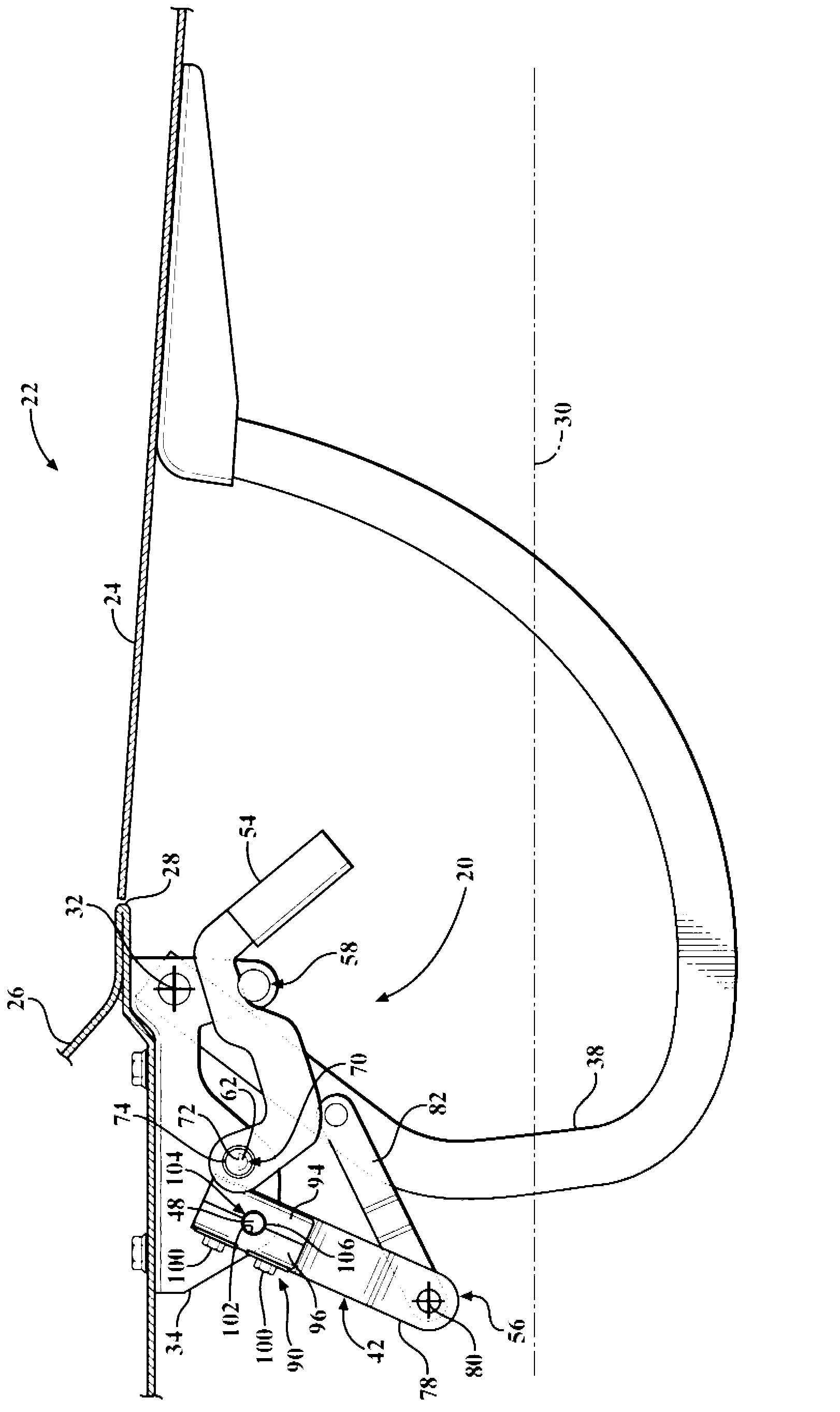

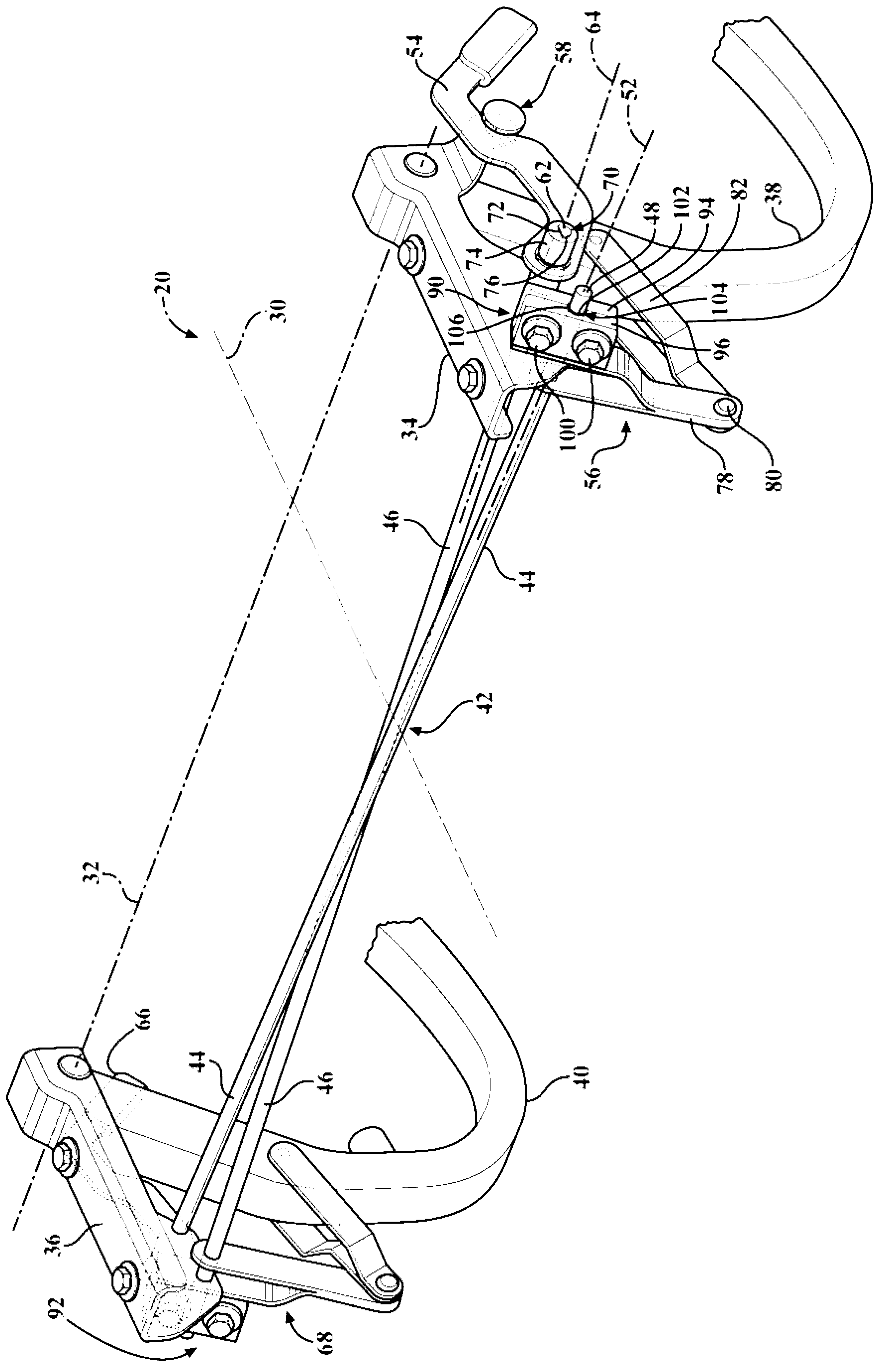

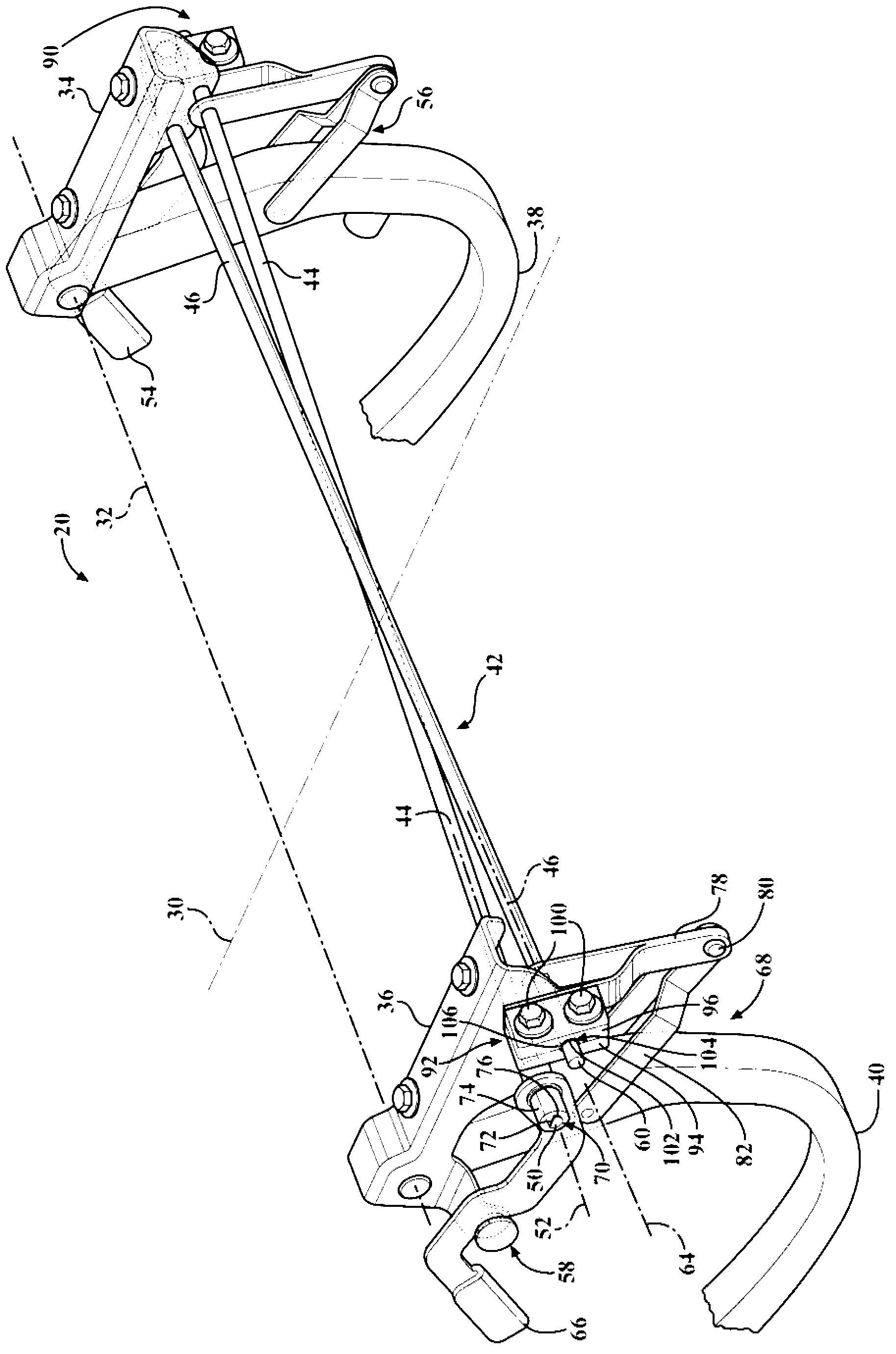

[0017] Referring to the drawings, wherein like numerals indicate like parts throughout the several views, a decklid hinge assembly (hereinafter hinge assembly) is shown generally at 20 . refer to figure 1 , a hinge assembly 20 for a vehicle 22 and rotatably connects a decklid 24 to a body 26 of the vehicle 22 . The decklid 24 seals an opening 28 defined by a body 26 , such as, for example, a trunk or cargo area of the vehicle 22 .

[0018] The body 26 extends along a longitudinal axis 30 between a front end of the body 26 and a rear end of the body 26 . The hinge assembly 20 rotatably connects the decklid 24 to the body 26 for rotation about an axis of rotation 32 . As shown, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com