Oil-gas separation gear and engine provided with same

A technology for separating gears and engines, which is applied to the lubrication of engine components, machines/engines, and engines. It can solve the problems of reducing engine life, lubricating oil loss, and component wear, and achieves increased service life, smooth lubrication, and solution The effect of oil loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

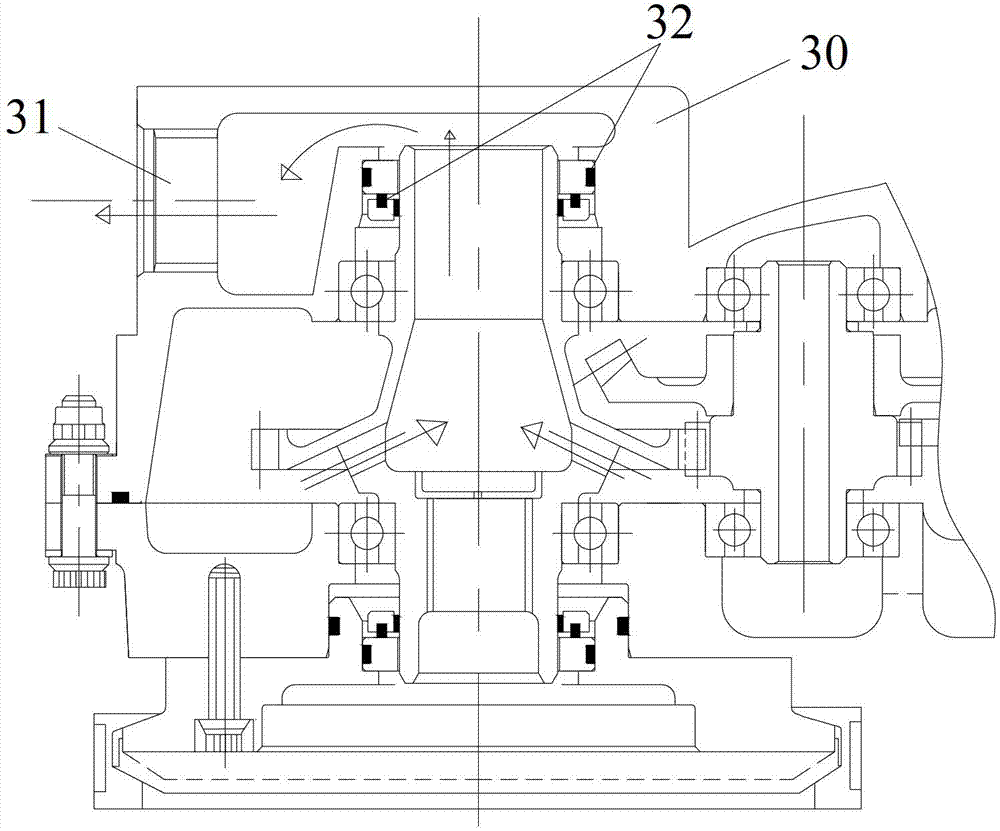

[0022] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

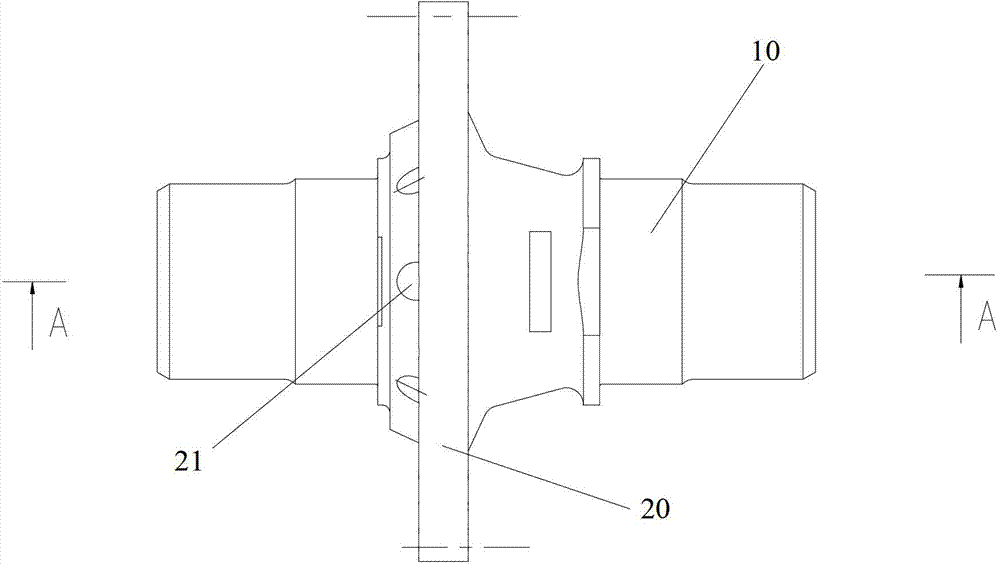

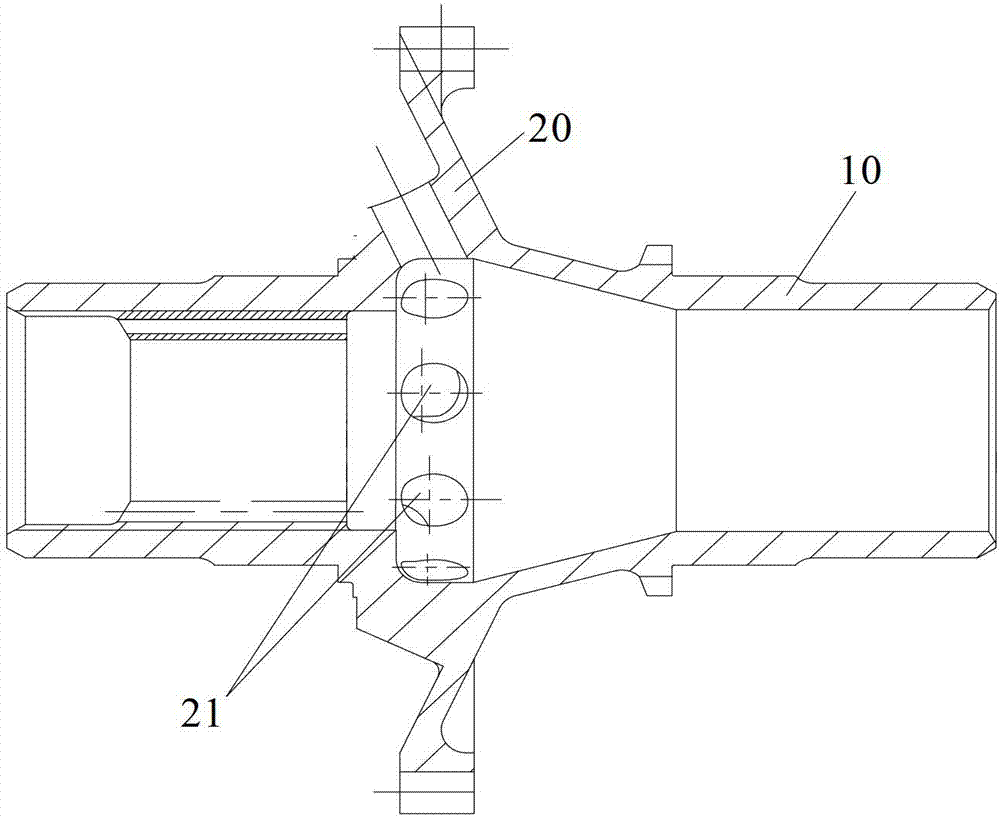

[0023] see Figure 1 to Figure 2 , according to the oil-gas separation gear of the present invention, comprising: a gear shaft 10, the gear shaft 10 is a hollow structure; a web 20 is arranged on the gear shaft 10, and the web 20 is provided with an inlet connected to the hollow structure of the gear shaft 10. There is an angle between the axial direction of the air oil rejection hole 21 and the axial direction of the air inlet oil rejection hole 21 and the gear shaft 10 . The material of the oil-gas separation gear is structural steel. The oil-gas separation gear of the present invention condenses the oil in the oil-gas mixture that enters through the air intake oil rejection hole on the wall of the air intake oil rejection hole through high-speed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com