Turning process method for large container component

A technology of container components and process methods, applied in the direction of load hanging components, transportation and packaging, etc., can solve the problems of difficult lifting and turning of large container components, reduce difficulty and risk, increase frictional resistance, and avoid bearing shear force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

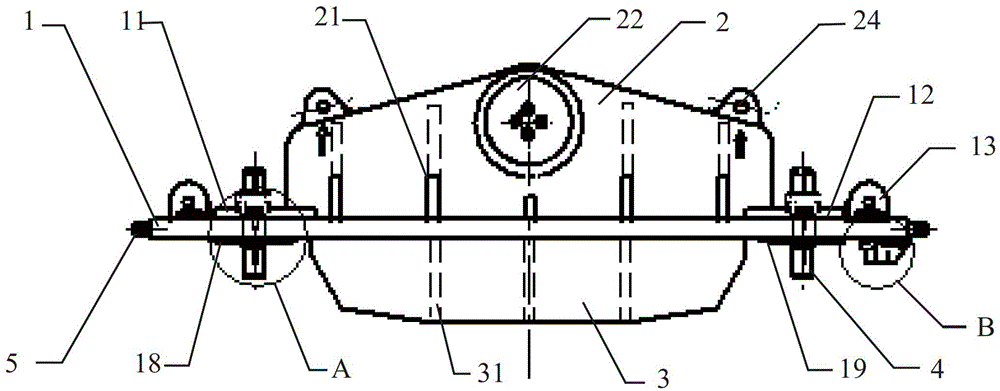

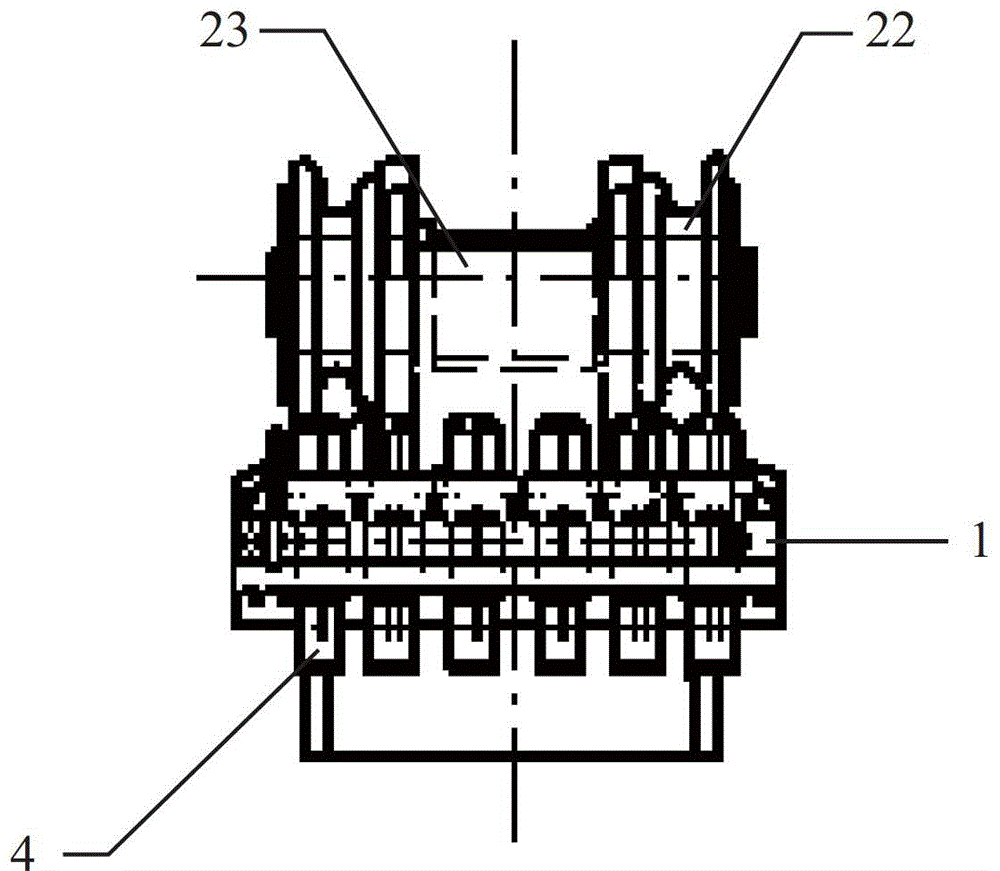

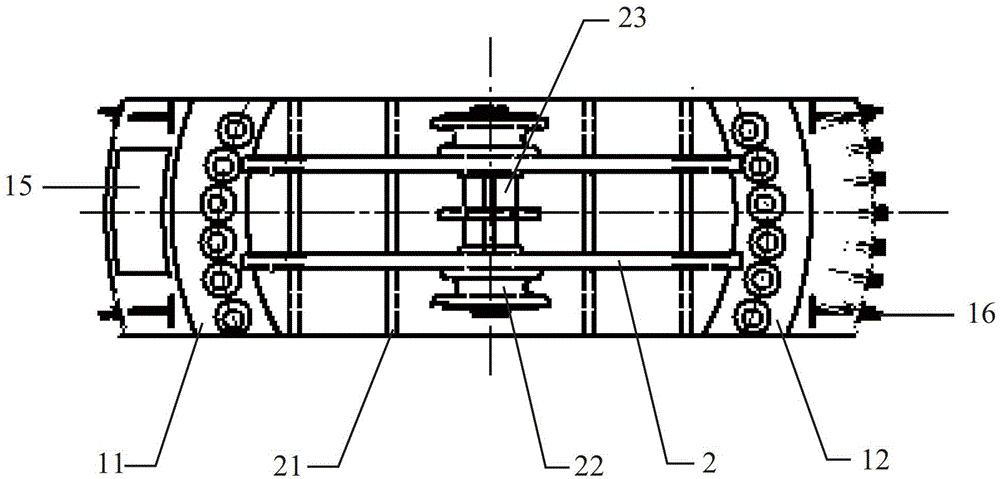

[0045] An overturning process method for a large container assembly, comprising the overturning of the container assembly from the vertical to the horizontal direction and the overturning of the container assembly from the horizontal to the vertical direction; figure 1 As shown), the hanger includes a main support plate 1, two parallel upper webs 2 fixed on the upper end of the main support plate 1 and two parallel lower webs fixed on the lower end of the main support plate 1 Plate 3, five ribs I21 are fixed between the two upper webs 2, and three ribs II31 are fixed between the two lower webs 3; the width between the two upper webs 2 Less than the width between the two lower webs 3 .

[0046] On the upper end surface of the main support plate 1 longer than the left and right end extensions of the upper web 2 and the lower web 3, a reinforcing plate I11 and a reinforcing plate II12 (such as image 3 shown), the reinforcement plate I11 and the reinforcement plate II12 are res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com