Forming method capable of customizing strength of ultrahigh-strength steel hot-stamped parts

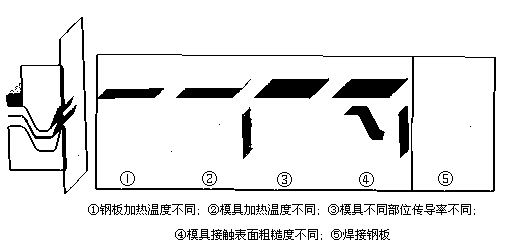

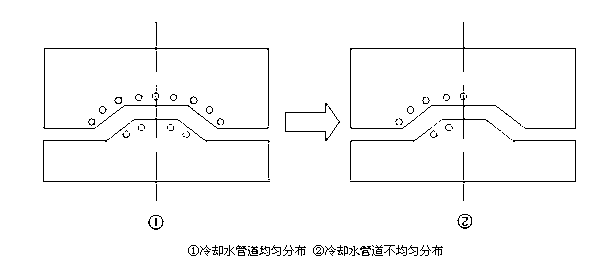

A technology for hot stamping and ultra-high strength steel, applied in the field of hot stamping, can solve the problems of difficult realization methods, performance differences, complicated procedures, etc., and achieve the effect of simplifying the realization methods and procedures, optimizing the overall performance, and realizing continuous changes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention is an example with a kind of simple performance requirement automobile structure, and concrete implementation method is as follows:

[0040] 1. This method uses 22MnB5 steel, the thickness of the steel plate is 1.6mm, and its specific composition is shown in the following table:

[0041] Table 2 Specific composition of 22MnB5 ultra-high strength steel %

[0042] C Si mn P S Al Cr B Ti Fe 0.233 0.260 1.100 0.009 <0.005

0.042 0.182 0.0038 0.029 Bal.

[0043] 2. The performance requirements to be achieved by a certain automotive structural part: some require ultra-high strength, the tensile strength reaches Rm≥1500MPa, and the elongation A=5%. The other part requires elongation A≥15%, and the tensile strength only needs to reach Rm=600MPa. In the middle, the strength of the transition area needs to change continuously, such as Figure 5 shown. This part just has better comprehensive protection performance ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| microhardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com