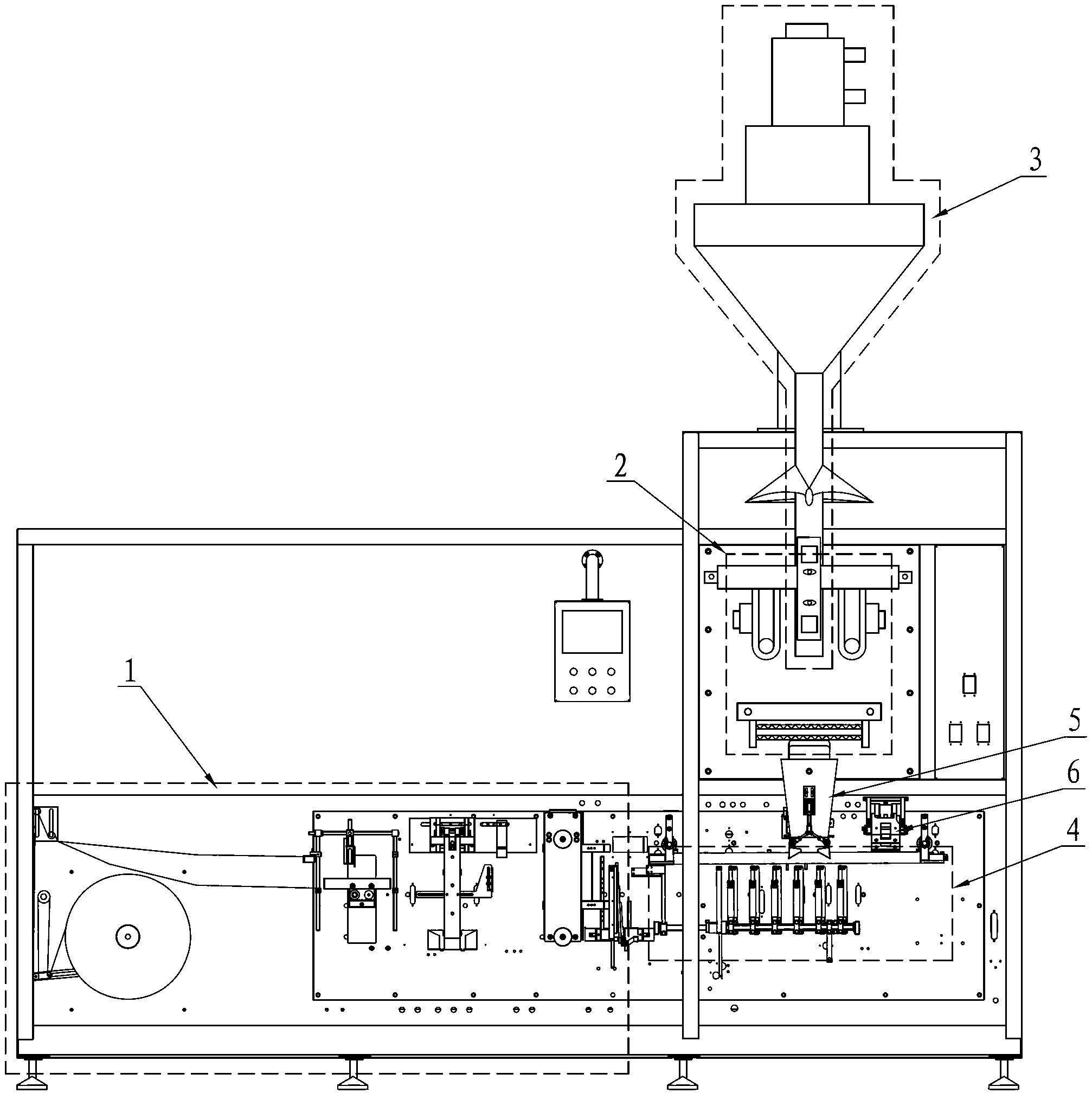

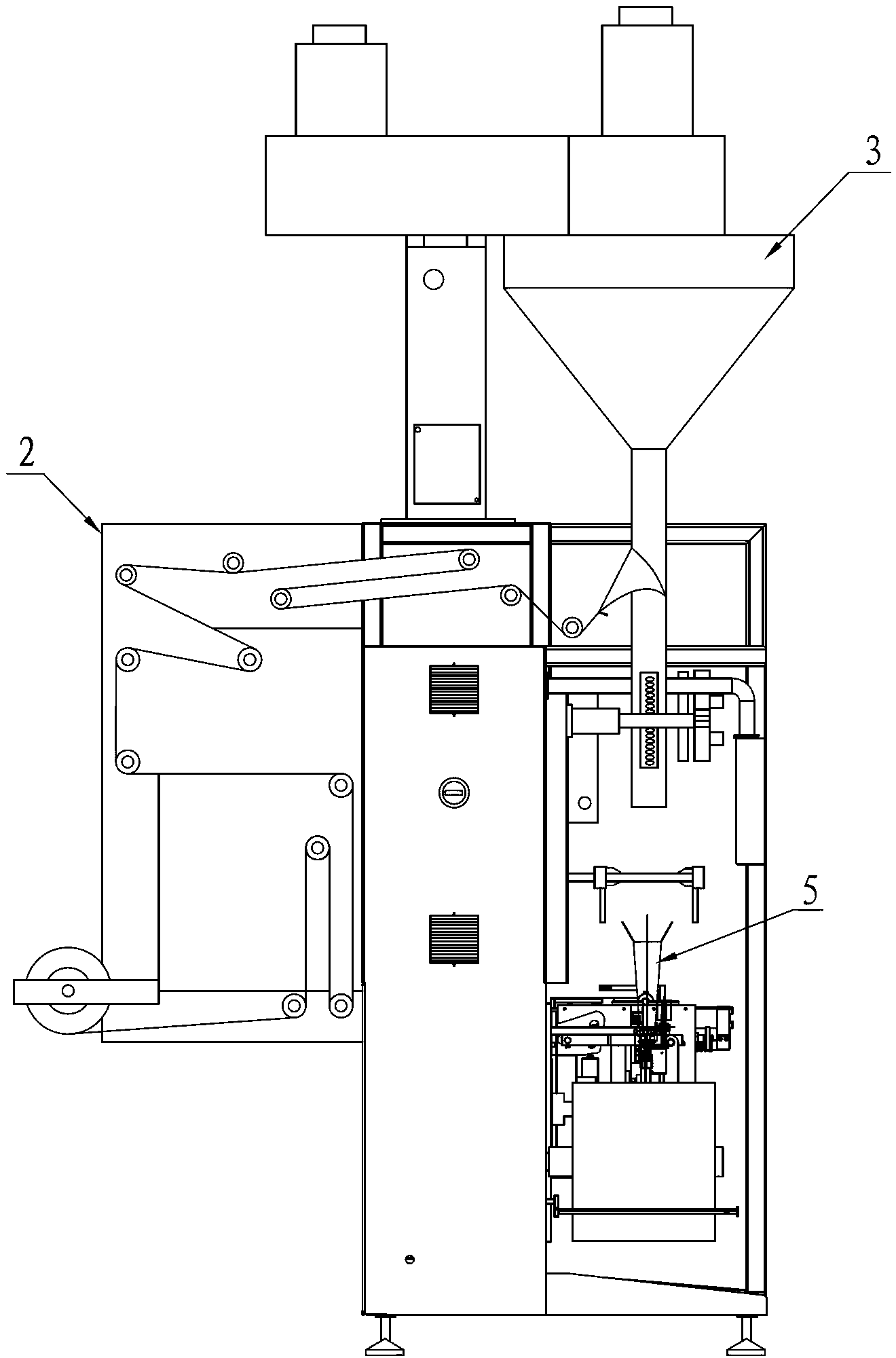

Horizontal sealing and shearing mechanism of inner bag of bag in bag packaging machine

A technology of cutting mechanism and packaging machine, applied in the direction of packaging, etc., can solve the problems of low work efficiency, high cost, and inability to meet the requirements of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

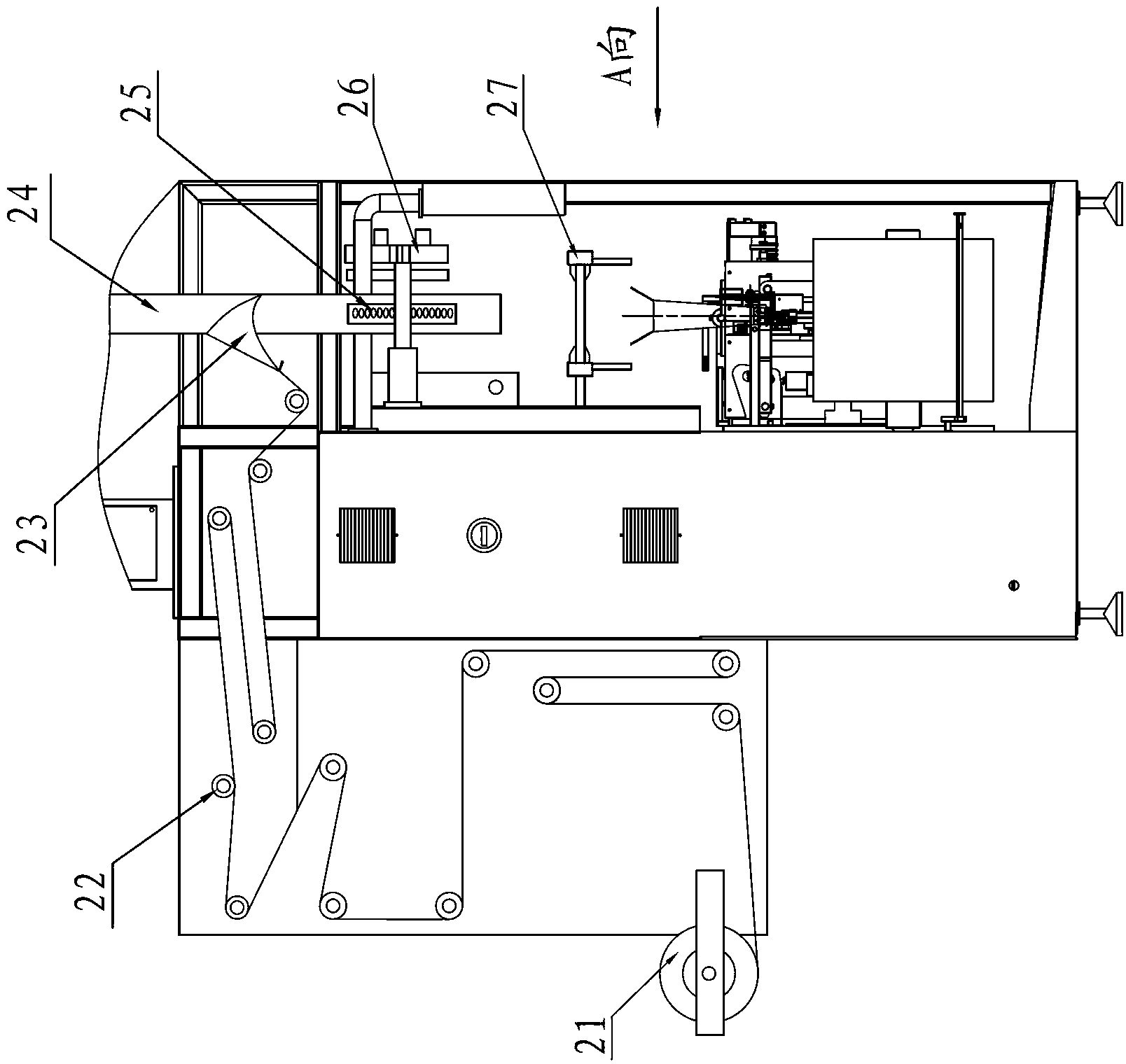

Embodiment

[0017] Embodiment: A horizontal sealing and shearing mechanism for the inner bag of a bag-in-bag packaging machine, including a horizontal sealing servo motor 271, an S-shaped connecting rod 272, an outer pulling cross bar 273, an outer ironing block fixing plate 274, and an inner pulling cross bar 275 , the inner ironing block fixed plate 276, the outer guide rod 277, the inner guide rod 278 and the fixed guide block 279, the horizontal seal servo motor 271 and the fixed guide block 279 are all fixed on the frame, the center of the S-shaped connecting rod 272 and the horizontal seal The output shaft of the servo motor 271 is fixedly connected, and the two ends of the S-shaped connecting rod 272 are hingedly connected with the outer pull cross bar 273 and the inner pull cross bar 275 respectively, and the two outer guide rods 277 pass through the corresponding fixed guide block 279 and the machine respectively. frame, the inner pull cross bar 275 and the inner ironing block fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com