Calibration apparatus used for fineness of grind gauge and calibration method used for chute bottom plane of fineness of grind gauge

A technology of scraper fineness meter and verification device, which is applied in measuring device, electromagnetic measuring device, electric/magnetic roughness/irregularity measurement, etc. The verification requirements of the value error and the incomplete positioning reference of the scraper indicator error verification method have achieved the effect of perfecting the verification technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

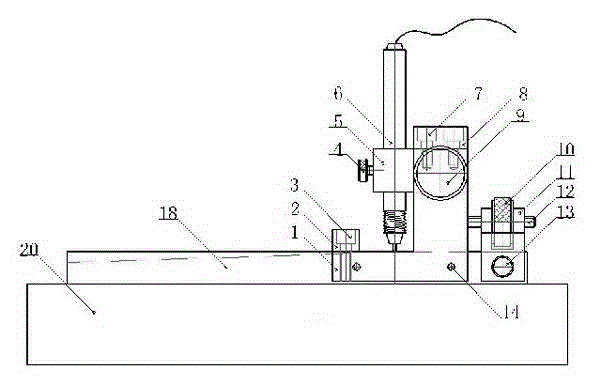

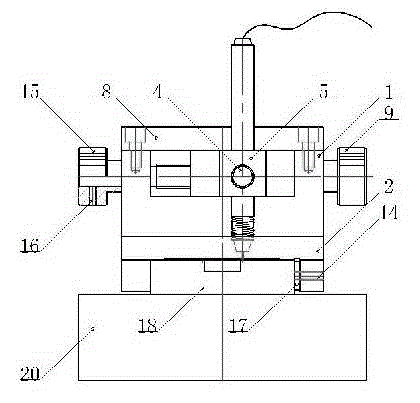

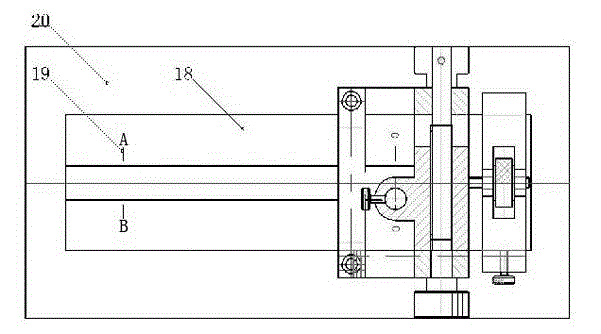

[0028] Example 1, such as figure 1 , figure 2 As shown, a scraper fineness meter verification device includes a device body, which is characterized in that: the device body is composed of a positioning mechanism for elastic positioning, a lateral displacement measurement mechanism for axial movement limit, and locking The positioning longitudinal alignment fine-tuning mechanism is composed of a base 1, a positioning pressure plate 2, a pressure plate screw 3, a positioning reed 17, and a positioning reed screw 14. The positioning pressure plate 2 is fixed on the base by two pressure plate screws 3 1. On the working surfaces on both sides of the bottom end, the positioning reed 17 is connected to the base 1 below the positioning pressure plate 2 by the positioning reed screw 14 to realize elastic positioning. The lower working surface of the positioning pressure plate 2 and the lower working surface of the base 1 share On the surface, the positioning reference is formed under...

Embodiment 2

[0034] Example 2, such as figure 1 , figure 2As shown, a scraper fineness meter verification device includes a device body, which is characterized in that: the device body is composed of a positioning mechanism for elastic positioning, a lateral displacement measurement mechanism for axial movement limit, and locking The positioning longitudinal alignment fine-tuning mechanism is composed of a base 1, a positioning pressure plate 2, a pressure plate screw 3, a positioning reed 17, and a positioning reed screw 14. The positioning pressure plate 2 is fixed on the base by two pressure plate screws 3 1. On the working surfaces on both sides of the bottom end, the positioning reed 17 is connected to the base 1 below the positioning pressure plate 2 by the positioning reed screw 14 to realize elastic positioning. The lower working surface of the positioning pressure plate 2 and the lower working surface of the base 1 share On the surface, the positioning reference is formed under ...

Embodiment 3

[0040] Example 3, such as figure 1 , figure 2 As shown, a scraper fineness meter verification device includes a device body, which is characterized in that: the device body is composed of a positioning mechanism for elastic positioning, a lateral displacement measurement mechanism for axial movement limit, and locking The positioning longitudinal alignment fine-tuning mechanism is composed of a base 1, a positioning pressure plate 2, a pressure plate screw 3, a positioning reed 17, and a positioning reed screw 14. The positioning pressure plate 2 is fixed on the base by two pressure plate screws 3 1. On the working surfaces on both sides of the bottom end, the positioning reed 17 is connected to the base 1 below the positioning pressure plate 2 by the positioning reed screw 14 to realize elastic positioning. The lower working surface of the positioning pressure plate 2 and the lower working surface of the base 1 share On the surface, the positioning reference is formed under...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com