Shot processing apparatus and shot processing method

A shot peening and clamping device technology, used in used abrasive treatment devices, abrasive blasting machine tools, metal processing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

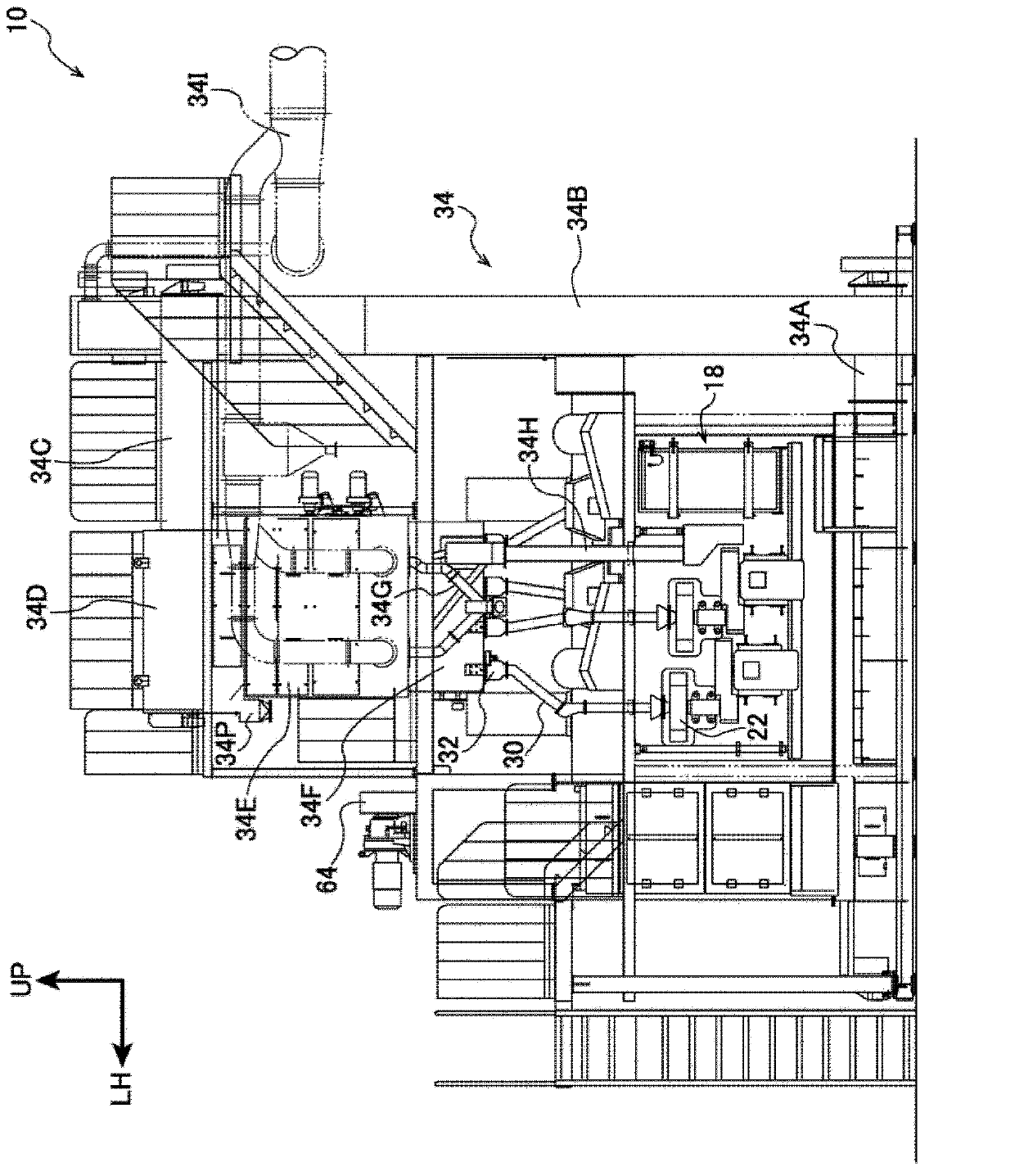

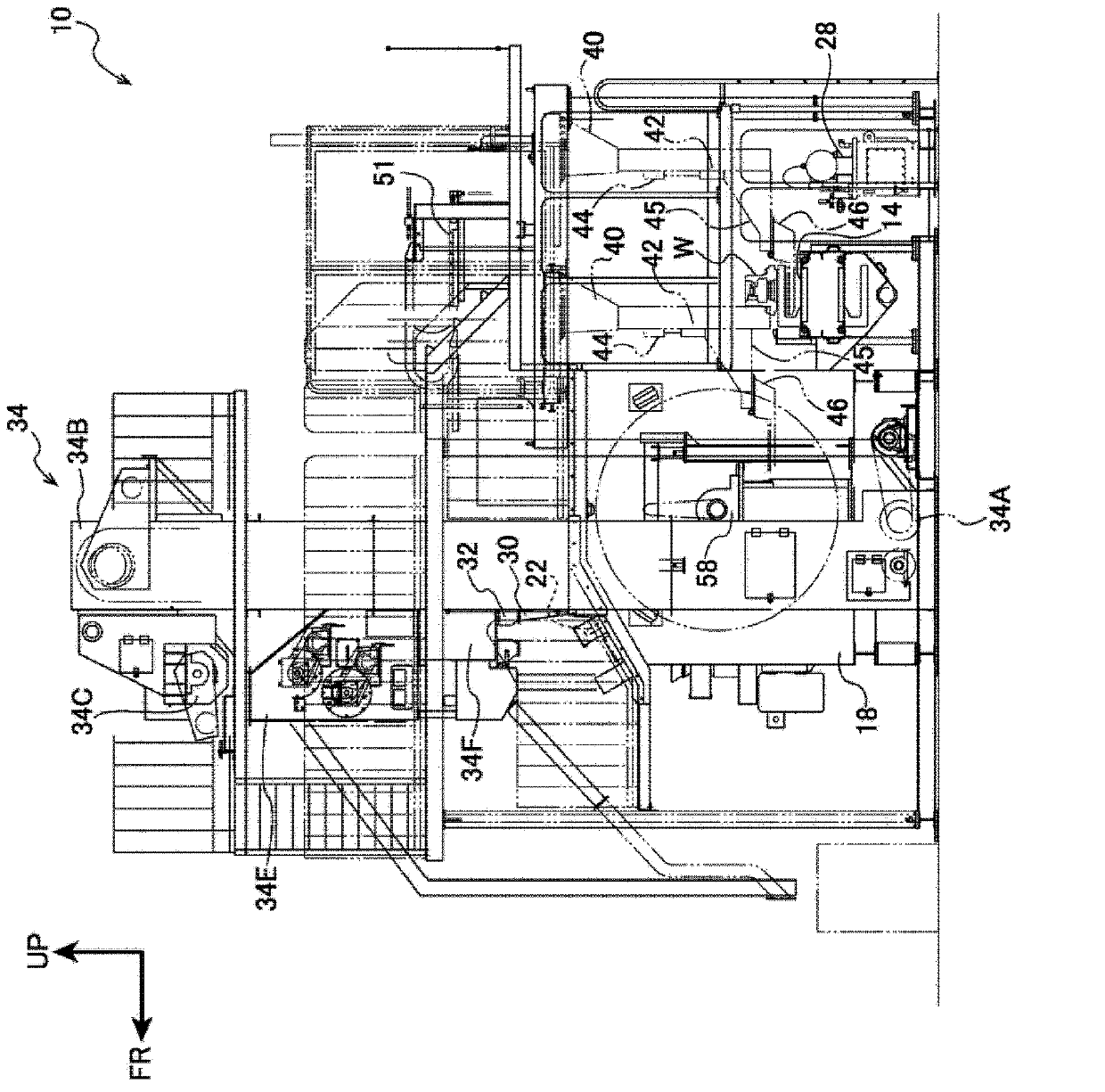

[0035] Hereinafter, the shot blasting apparatus 10 which is one Embodiment of the shot processing apparatus of this invention is demonstrated based on drawing. In addition, arrow FR appropriately shown in these figures indicates the near side when viewing the device from the front, arrow UP indicates the upper side of the device, and arrow LH indicates the left side when viewing the device from the front.

[0036] figure 1 is a front view of the shot blasting device 10, figure 2 is the right side view of the shot blasting device 10, image 3 It is a left side view of the shot blasting apparatus 10. in addition, Figure 4 is the rear view of the shot blasting device 10, Figure 5 is a top view of the shot blasting device 10, Figure 6 It is a horizontal sectional view of the shot blasting apparatus 10.

[0037] In addition, the workpiece|work W which is the object to be processed which receives shot blasting in the shot blasting apparatus 10 is a casting casted using a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com