Double-drive drilling machine

A technology for drilling and excavating, water intake, applied in the direction of earth moving machine/shovel, construction, etc., can solve problems such as low efficiency, and achieve high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

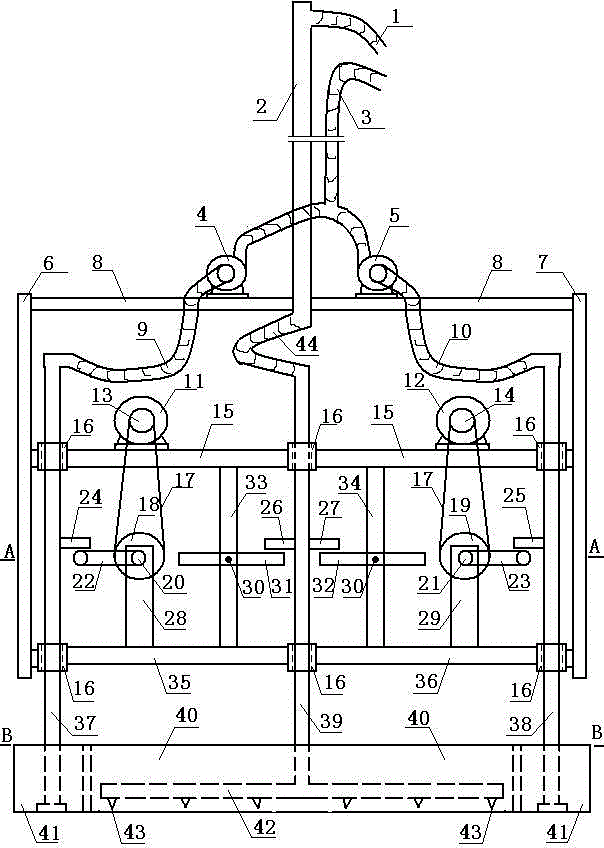

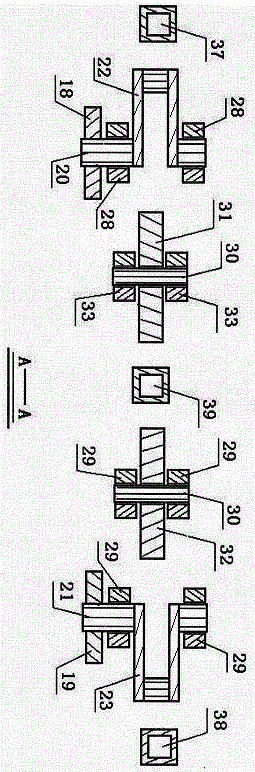

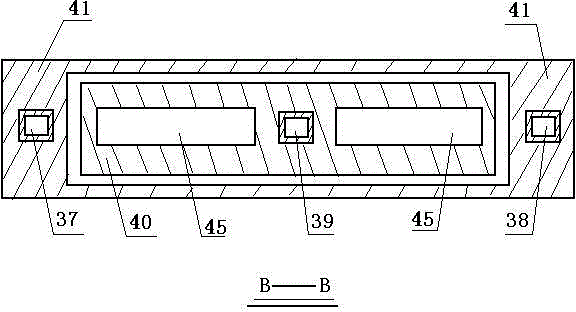

[0013] The accompanying drawing is a specific embodiment of the present invention. In this embodiment, the water inlet steel pipe 2 can be lengthened section by section as the depth of the groove increases. 44 is connected to the upper end of the square pipe 39, the lower part of the square pipe is fixed to the hammer A 40, the lower end of the square pipe is connected to the water pipe 42, and the water nozzle 43 is provided at the lower part of the water pipe; the lower end of the drainage rubber pipe 3 is respectively connected to the first sand pump 4 through two branch pipes The outlet of the first sand pump and the outlet of the second sand pump 5, the first sand pump and the second sand pump are installed on the first rod 8, and the suction port of the first sand pump is connected to the left side pipe 37 through the left water suction hose 9 The upper end, the lower part of the left pipe is fixed to the left part of the B hammer 41, the lower end of the left pipe is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com