crankshaft trencher

A trench digger and crankshaft technology, which is applied in the direction of earth mover/shovel, construction, etc., can solve the problems of high equipment cost, low efficiency, unreliable performance, etc., and achieve low construction equipment cost, reliable performance and high efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

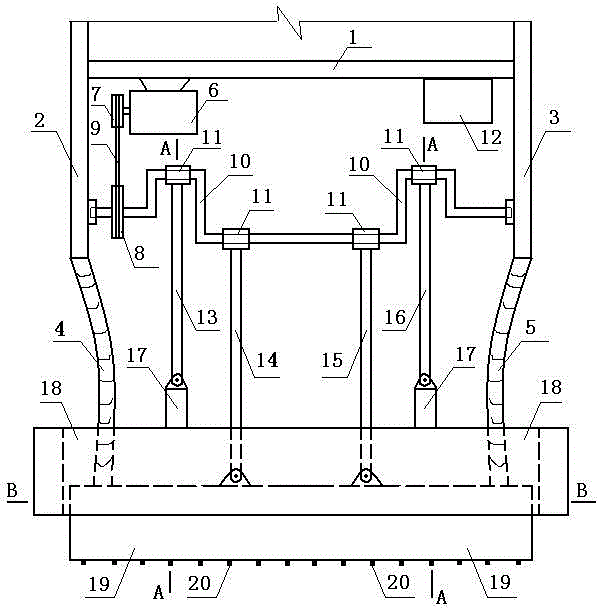

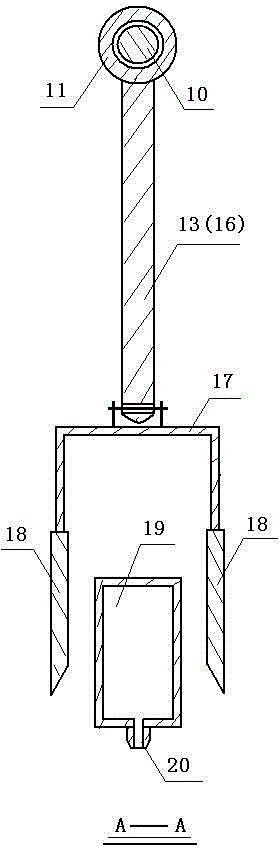

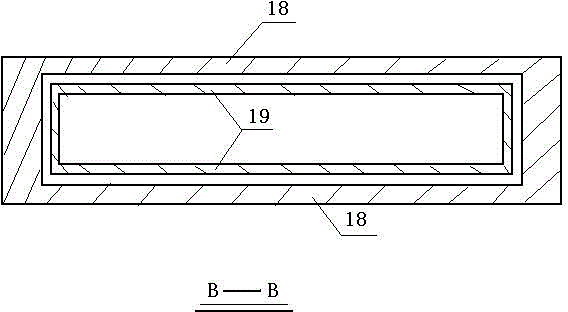

[0013] Accompanying drawing is a kind of specific embodiment of the present invention, and this embodiment is provided with side rod A2 on the left side, and side rod B3 is provided on the right side, and the lower end of side rod A is connected with flexible pipe A4, and the lower end of flexible pipe A is connected with the left end of impact block B19, and The lower end of the rod B is connected to the hose B5, and the lower end of the hose B is connected to the right end of the impact block B; the connecting beam 1 connects the side rod A and the side rod B, the driving machine is arranged under the connecting beam, and the driving shaft of the driving machine is provided with a driving wheel 7 , the driving wheel is connected to the driven wheel 8 through the V-belt 9, the driven wheel is arranged at the left end of the crankshaft 10, the crankshaft is provided with four shaft joints, each shaft joint is provided with a shaft sleeve 11, and the left shaft sleeve is hinged t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com