Fully sealed airflow splitting and automatic feeding integrated device

An automatic material-receiving, fully-sealed technology, applied in the field of metal powder reduction processing machinery, can solve the problems of easy pollution, difficult recovery and removal of material powder, etc., and achieve the effect of ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

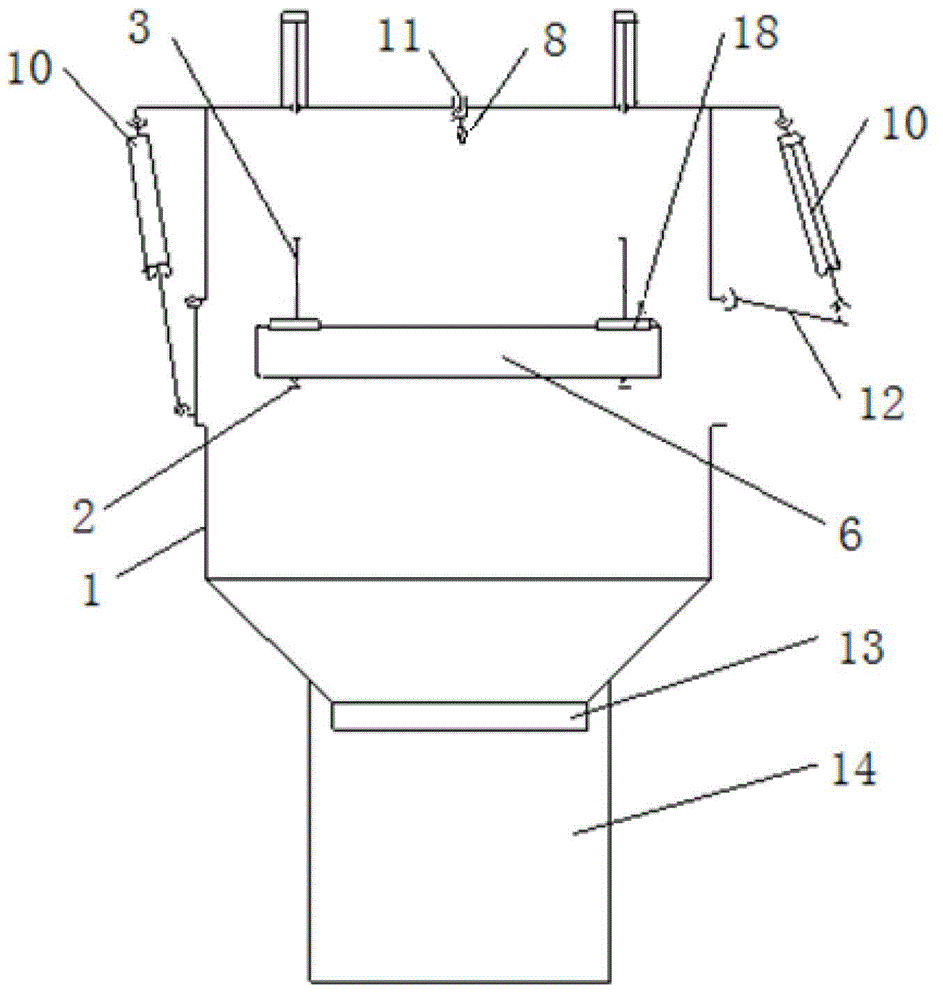

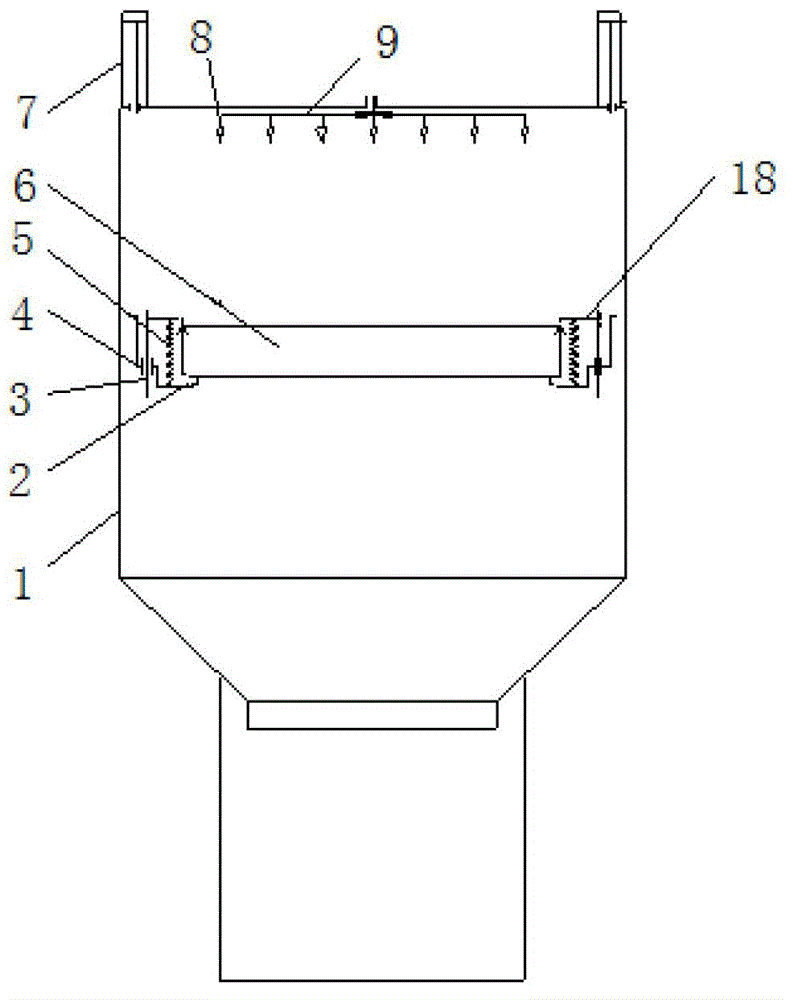

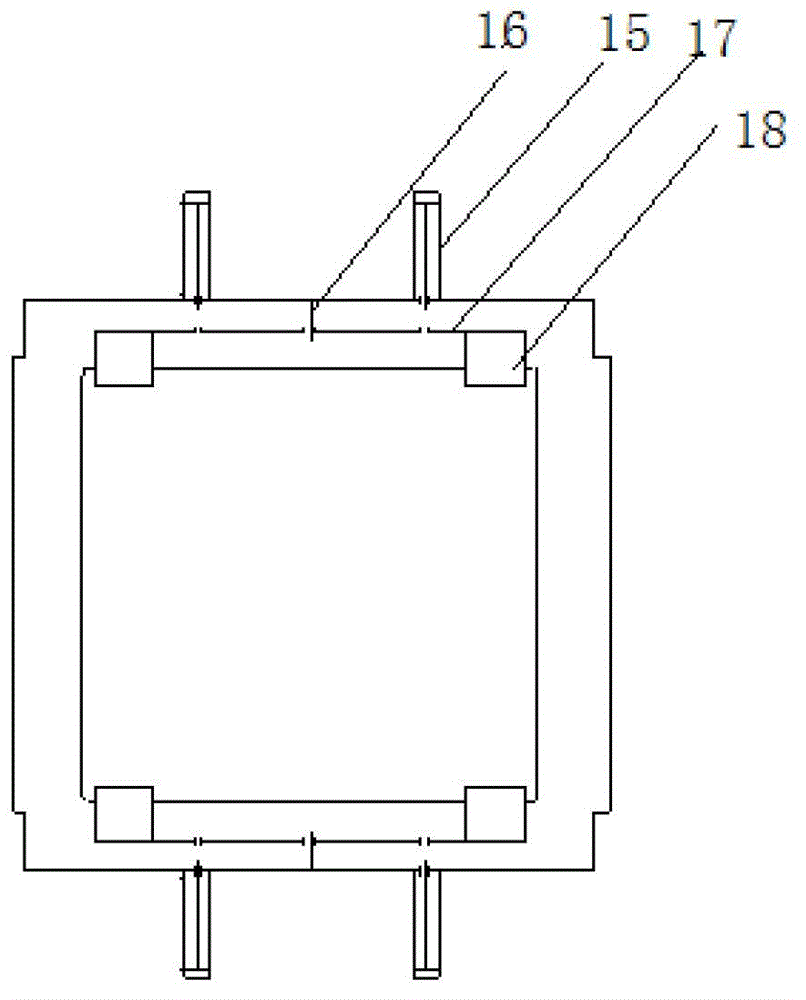

[0021] The present invention provides an integrated device for fully-sealed airflow splitting and automatic receiving, see figure 1 with figure 2 , including a hollow receiving bin 1, the two sides of the receiving bin 1 are provided with sealed door panels 12, each sealed door panel 12 is provided with an opening and closing cylinder 10, the bottom of the receiving bin 1 is provided with an opening, and the receiving bin 1 A recovery device is provided at the opening of the storage bin 1, and a material boat 6 is provided inside the receiving bin 1, and four sets of clamping devices are evenly provided on the edge of the feeding boat 6, and the inside of the receiving bin 1 is located above the feeding boat 6. Cracking device; mounting plates 17 are symmetrically arranged on both sides of the material boat 6, and anti-rotation cylinders 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com