Carbon supplementing method in hot working of steel

A thermal processing, steel technology, applied in the direction of metal material coating process, coating, solid diffusion coating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Embodiment 1: Hot-rolled spring flat steel products are produced in a rolling mill, the steel type is: 55SiCr, and the size is: 100×15mm.

[0014] The blank size is: 150×150mm.

[0015] Requirements: No complete decarburization, total decarburization layer: less than 0.2mm for grade 1, less than 0.25mm for grade 2.

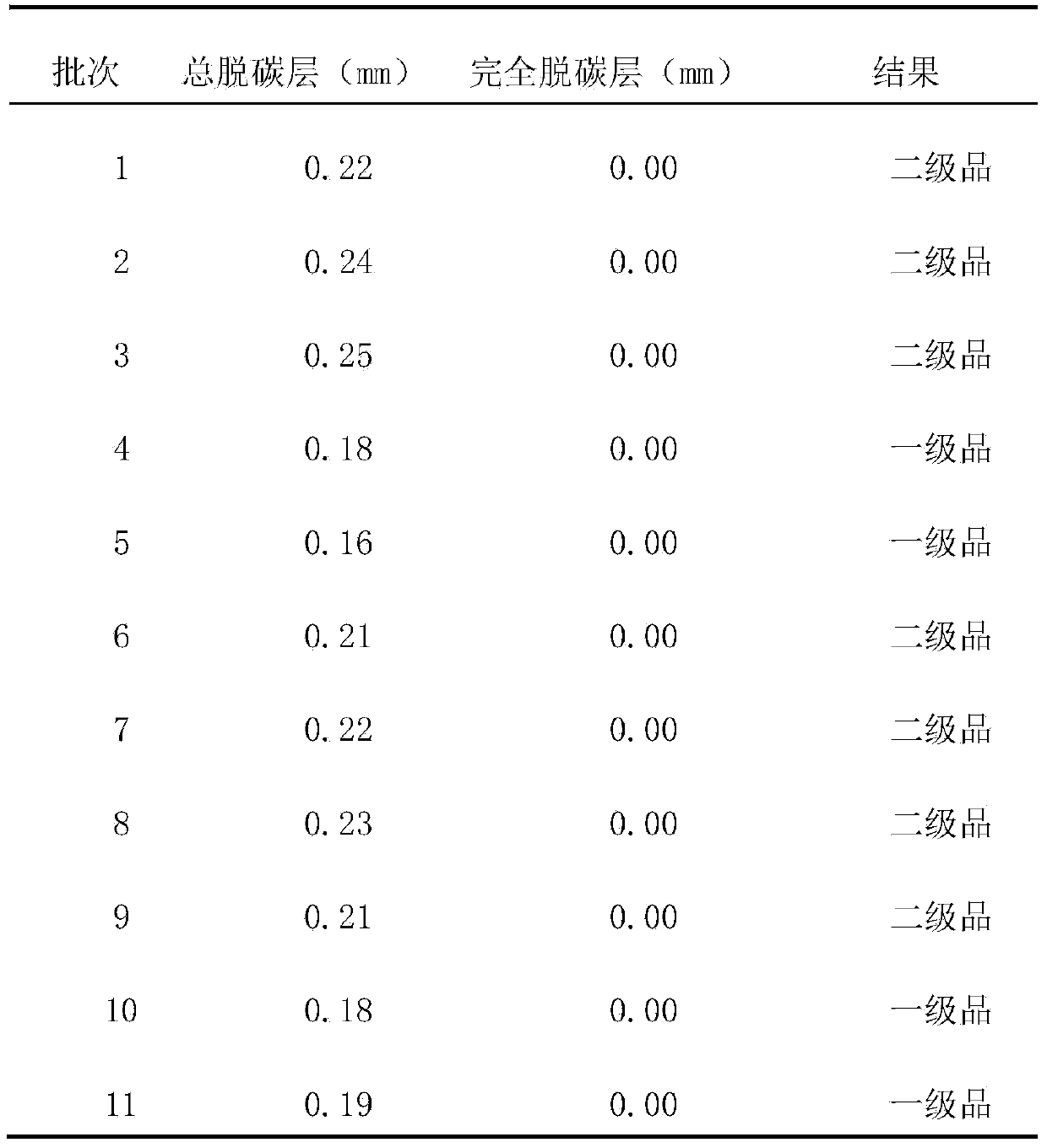

[0016] Apply the low-temperature hot rolling process commonly used at present, the heating temperature is 1130°C, the rolling start temperature is 1100°C, the final rolling temperature is 900°C, after 10 passes of rolling, and finally air-cooled. The decarburization of 11 batches of products was sampled and measured, as shown in Table 1:

[0017] Table 1 Decarburization results of common hot rolling process products

[0018]

[0019] It can be seen from Table 1 that there are 7 batches of secondary products and only 4 batches of first-class products.

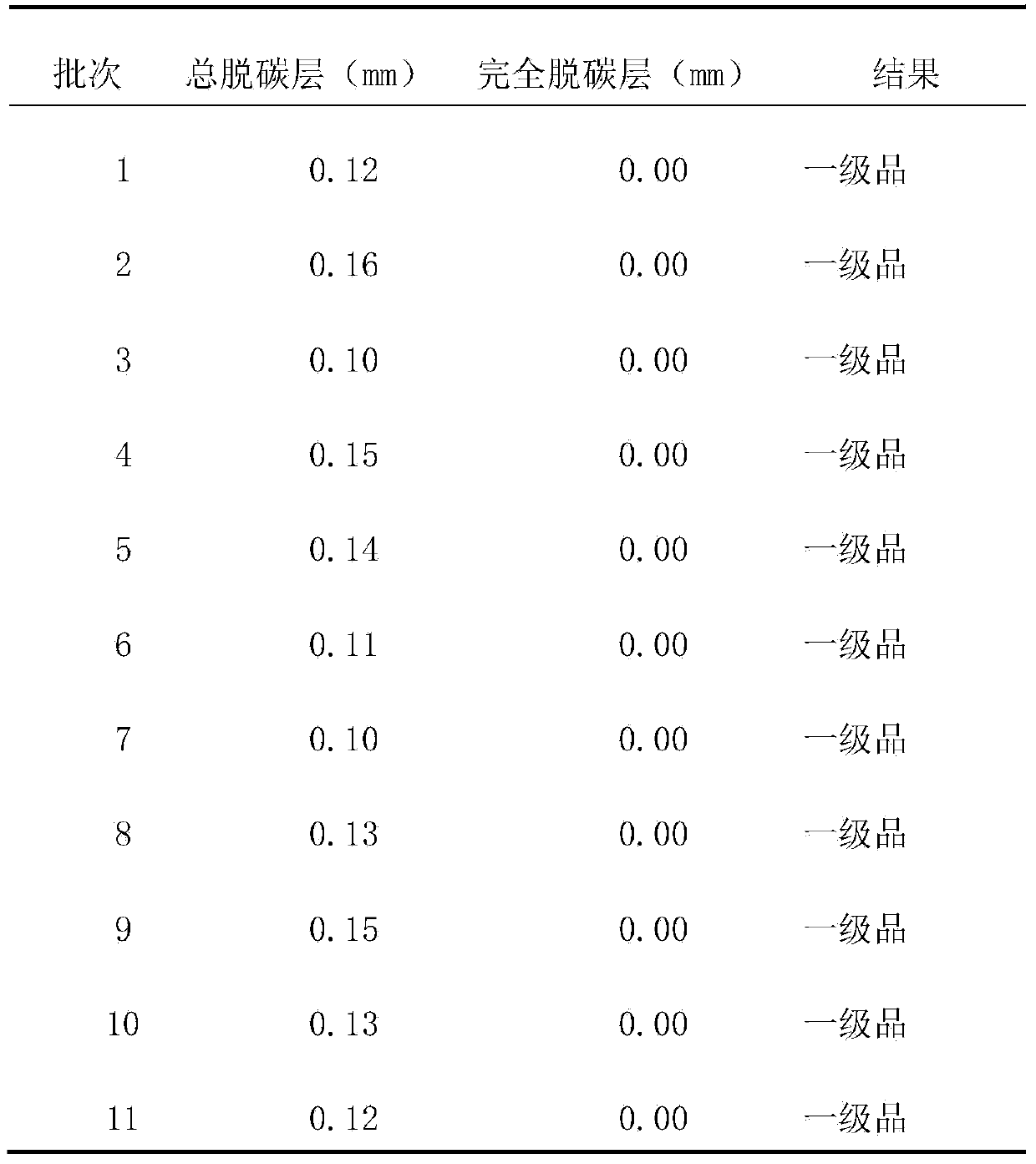

[0020] Using the thermal processing and cooling method provided by the present invention, the heatin...

Embodiment 2

[0024] Embodiment 2: hot-rolled spring steel and bars are produced in a rolling mill. Product, steel type: 60Si2Mn, size: φ25mm.

[0025] The blank size is: 160×160mm.

[0026] Requirements: No complete decarburization, total decarburization layer: less than 0.5mm for grade 1, less than 0.62mm for grade 2.

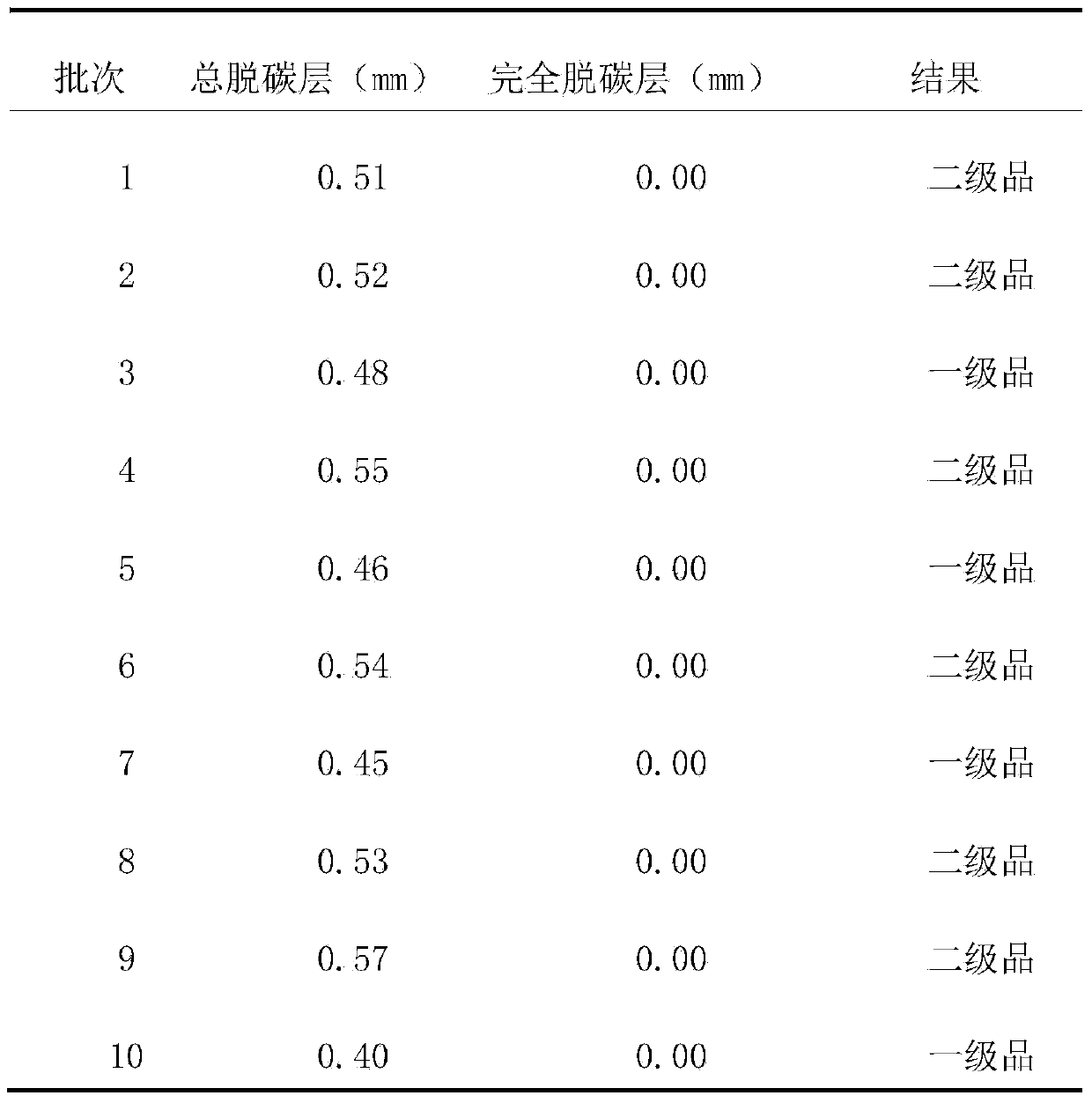

[0027] Apply the low-temperature hot rolling process commonly used at present, the heating temperature is 1130°C, the rolling start temperature is 1100°C, the final rolling temperature is 900°C, after 14 passes of rolling, and finally air-cooled. Samples were taken to measure the decarburization of 10 batches of products, as shown in Table 3:

[0028] Table 3 Decarburization results of ordinary hot rolling process products

[0029]

[0030] It can be seen from Table 3 that there are 6 batches of secondary products and 4 batches of first-class products.

[0031] Using the thermal processing and cooling method provided by the present invention, the heating temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com