Air layer knitted fabric plaiting double-layer knitting method and plaited fabric structure thereof

A knitted fabric and air layer technology, applied in the field of knitted fabrics, can solve the problems of easy deformation, loose structure, insufficient strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to facilitate the understanding of those skilled in the art, the principle of the present invention will be further described in detail below in conjunction with specific embodiments.

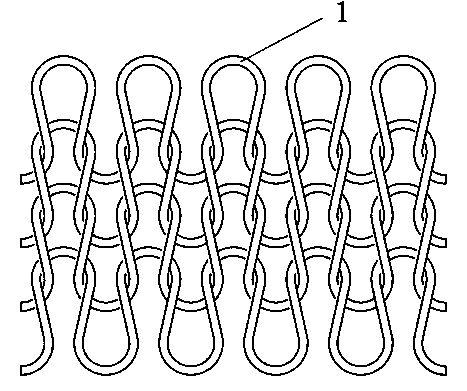

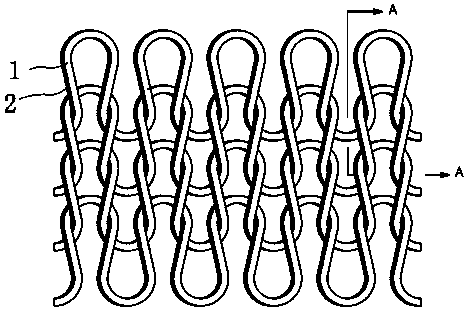

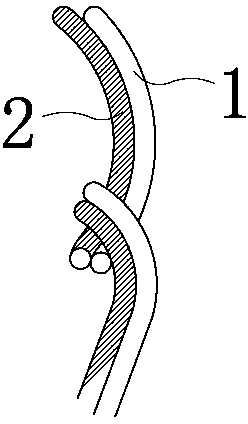

[0026] Such as figure 2 ~ As shown in Fig. 5, the present invention discloses a plated fabric structure made by using air-layer knitted fabric plated double-layer weaving method, including main yarn 1 for weaving, on which main yarn 1 is woven synchronously by plating method. Hot-melt yarn 2, hot-melt yarn 2 is adhered on the main yarn 1.

[0027] Such as figure 2 ~ As shown in Figure 3, a double-layer weaving method of plaiting air-layer knitted fabric is carried out on a large circular knitting machine equipped with an upper dial and a lower needle cylinder or a flat knitting machine with front and rear boards. The double-layer weaving method includes the middle The practice of adding hot-melt yarn connection measures; in the double-layer weaving method, double-hole yarn f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com