Cigarette filter containing ultralong TiO2 aquo-complex nanotube, TiO2 nanometer powder and activated carbon fiber

An activated carbon fiber and filter technology, which is applied in the fields of e-liquid filter, tobacco, food science, etc., can solve the problems such as being unsuitable for the large-scale production of cigarette filters, not easy to interweave and mix acetate fibers, and the degradation of ammonia and other components is not obvious. The adsorbent is not easy to interweave and mix with cellulose acetate, which solves the effect of insignificant degradation of various components and strong ammonia adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

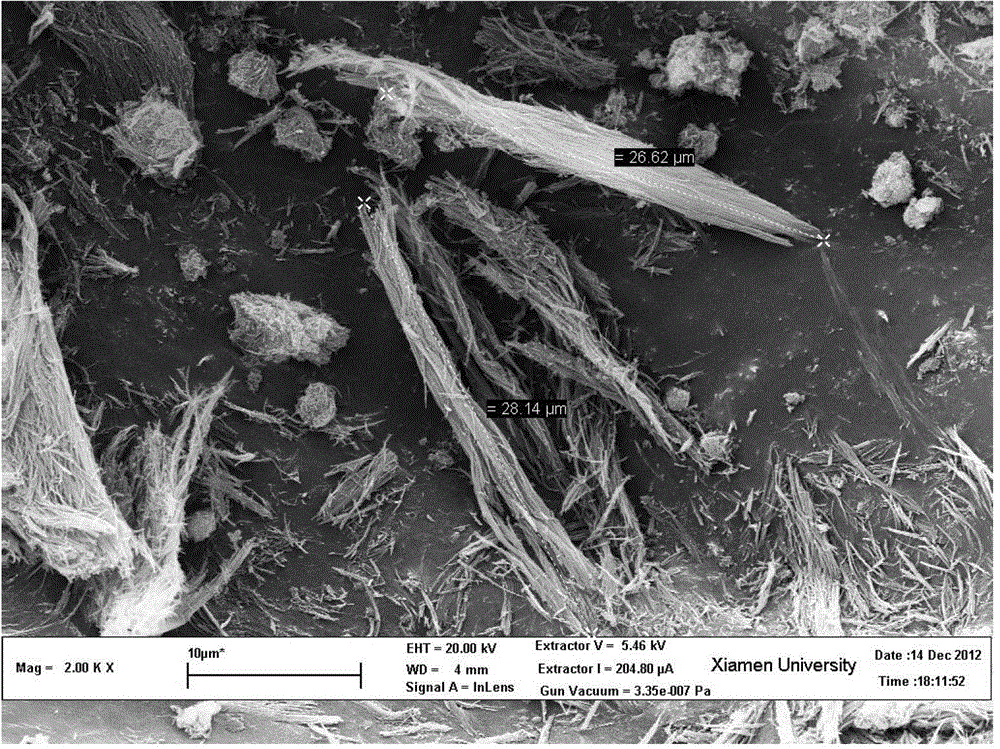

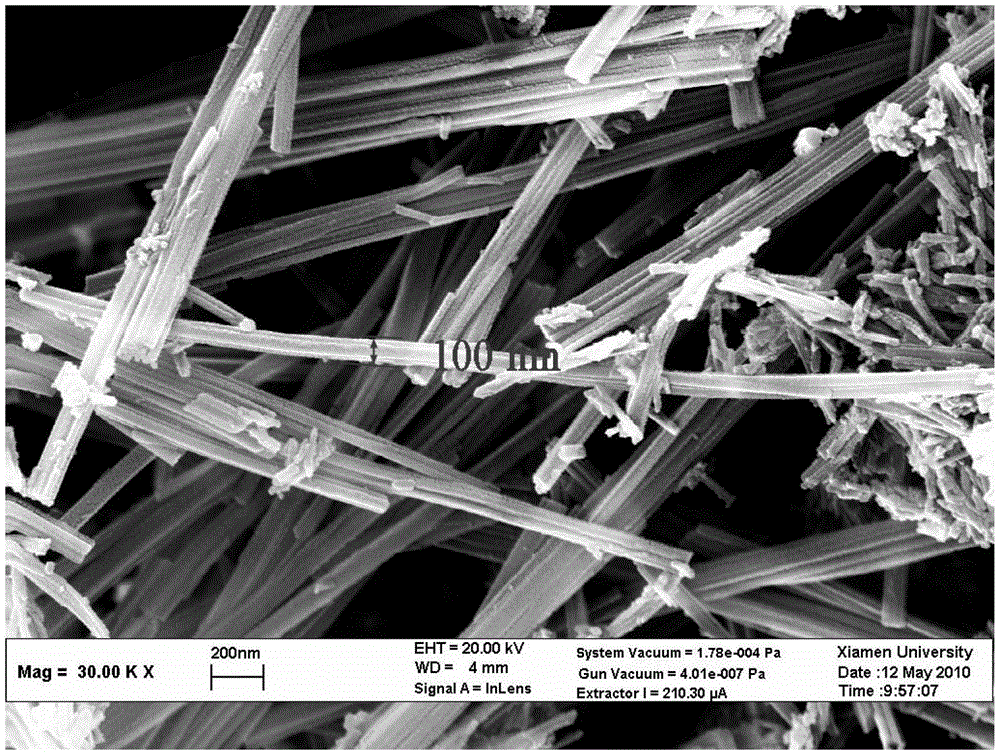

[0044] Example 1TiO 2 Preparation of Hydrate Nanotubes

[0045] 1. Preparation method:

[0046] Method 1: Add 2 g of commercial grade TiO 2 (P25) was dissolved in 75ml of 10M NaOH solution, the mixture was transferred into a 100mL autoclave and placed in an oil bath, and heated in water at a temperature range of 150°C and a speed of 10r / min for 24h. After the reaction, the white precipitate obtained was washed with distilled water until neutral, then soaked in acid solution for 24 hours, then filtered and washed until neutral, and dried at 60°C to finally obtain TiO 2 Hydrate nanotubes.

[0047] Method 2: Add 0.1 g of commercial grade TiO 2 (P25) was dissolved in 75ml of 8M NaOH solution, and the mixture was transferred into a 100mL autoclave and placed in an oil bath, and hydrothermally heated at a temperature range of 200°C and a speed of 5r / min for 18h. After the reaction, the white precipitate obtained was washed with distilled water until neutral, then soaked in acid...

Embodiment 2

[0051] The preparation of embodiment 2 cigarette filter tip

[0052] 1. Raw material

[0053] Processing raw material: TiO 2 Nano powder, purchased from ISHIHARA SANGYO KAISYA, LTD.; Acetate fiber, purchased from Guizhou China Tobacco Industry Co., Ltd.; activated carbon fiber, purchased from Nantong Xintong Activated Carbon Fiber Co., Ltd., its specific surface area is 1200m 2 / g.

[0054] 2. Preparation of Cigarette Filters

[0055] method one:

[0056] The TiO prepared by embodiment 1 2 Hydrate nanotubes and acetate fibers are interwoven and mixed, and then doped with activated carbon fibers and TiO 2 Nano-powder, interweaving and mixing evenly, to prepare the adsorption filter layer of cigarette filter, in which TiO 2 The mass of hydrate nanotubes is 10% of the total mass of acetate fibers in cigarette filters, TiO 2 The mass of nano powder is TiO 2 5% of the mass of hydrate nanotubes, the mass of activated carbon fibers is TiO 2 5% of the mass of hydrate nanotub...

Embodiment 3

[0064] Example 3 Detection of Filter Adsorption Filtration Effect

[0065] 1. Experimental method

[0066] Prepare filter tip according to embodiment 2, adsorption filter layer is positioned at filter stick front end, wherein TiO in the adsorption filter layer 2 The mass of hydrate nanotubes is 10% of the total acetate mass, TiO 2 The mass of nano powder is TiO 2 5% of the mass of hydrate nanotubes, and the mass of activated carbon fibers is TiO 2 5% of the mass of hydrate nanotubes; cigarettes are prepared with the above-mentioned filter tip.

[0067] Control: As a control, cigarettes were prepared using a filter tip composed entirely of cellulose acetate.

[0068] Detection method: reference to the detection method of filter adsorption and filtration effect: YC / T377-2010 Determination of ammonia in mainstream smoke of cigarettes; 2009 Determination of carbon monoxide in the gas phase of cigarette smoke.

[0069] 2. Experimental results

[0070] The test results of red...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com