Cigarette with traditional smoke dilution process modified

A traditional smoke and cigarette technology, applied in tobacco, cigar manufacturing, application, etc., can solve the problems of poor sensory quality of smoke, affecting the quality of cigarette smoking, and reducing the resistance of cigarettes, so as to reduce the feeling of emptying, The effect of improving the suction resistance and maintaining the suction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

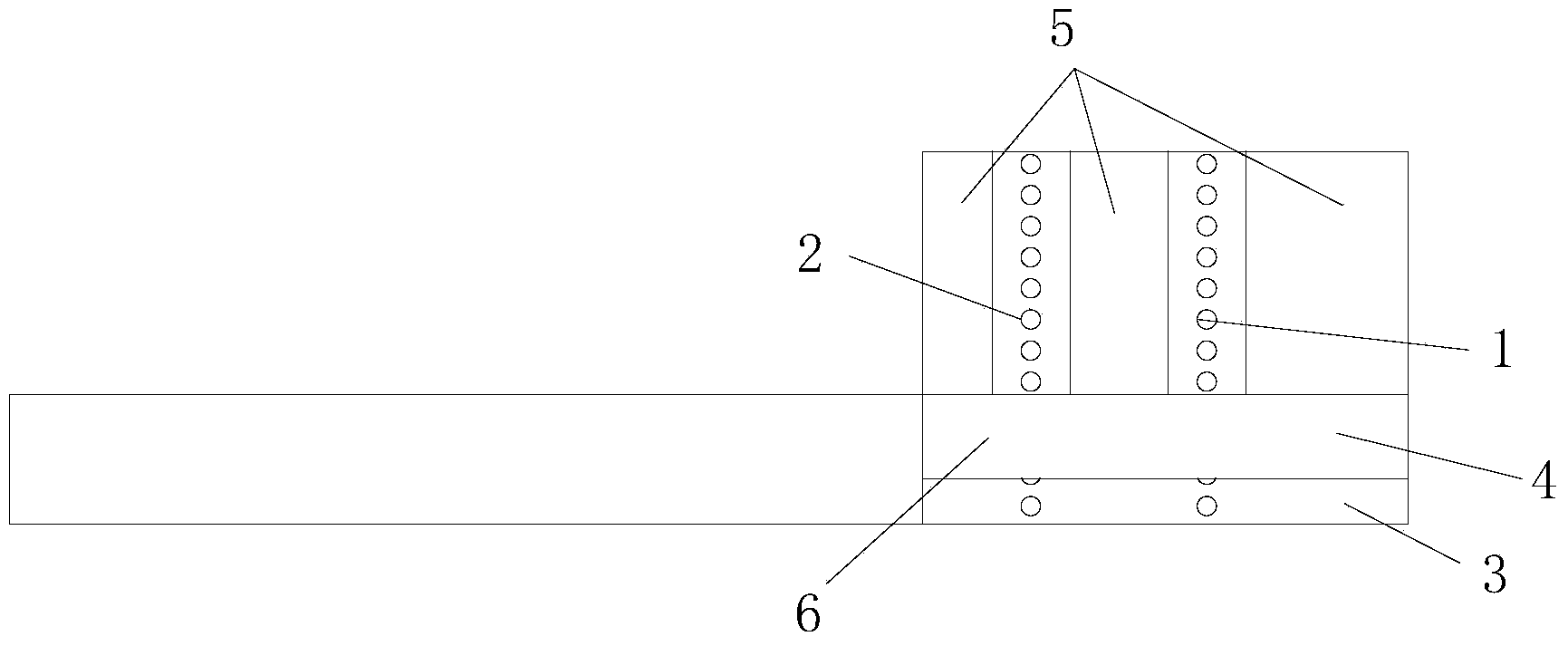

[0016] The length of the tipping paper after rolling is 32mm, and the total length of the cigarette is 84mm. The tipping paper has two ventilation hole zones. The first ventilation hole zone is 5mm wide and has a row of holes. The distance between the hole zone and the mouth end is 12.5mm. , the air permeability of the hole belt is 200CU; the width of the second ventilation hole zone is 8mm, there are two rows of holes, the distance between the center of the hole belt and the mouth end is 20.5mm, and the air permeability of the hole belt is 800CU; The distance between the hole belts is 8mm, the tipping paper and the forming paper are separated by the glue area, and the single-ventilation cigarette and the double-ventilation cigarette are rolled according to the ventilation rate of 61%, and the cigarettes are tested by Borgwatt comprehensive tester Physical parameters and smoke analysis using a smoking machine. The open draw resistance of double-ventilated cigarettes is 760Pa, ...

Embodiment 2

[0018] The length of the tipping paper after rolling is 34mm, and the total length of the cigarette is 84mm. The tipping paper has two ventilation hole zones, the first ventilation hole zone is 5mm wide, and a row of holes. The distance between the hole zone and the mouth end is 11.5mm , the air permeability of the hole belt is 200CU; the width of the second ventilation hole is 5mm, a row of holes, the distance between the position of the hole belt and the mouth end is 26.5mm, and the air permeability of the hole belt is 300CU; the distance between the center distance of the two ventilation hole belt areas 15mm, the tipping paper and the forming paper between the hole belts are bonded and separated by the glue area. According to the ventilation degree of 36.4%, single-ventilation cigarettes and double-ventilation cigarettes are rolled, and the physical parameters of the cigarettes are tested by Borgwatt comprehensive tester Smoking machine for smoke analysis. The open draw res...

Embodiment 3

[0020] The length of the tipping paper after rolling is 39mm, the total length of the cigarette is 84mm, the tipping paper has two ventilation hole zones, the first ventilation hole zone is 5mm wide, a row of holes, the distance between the center of the hole zone and the mouth end is 8mm , the air permeability is 200CU; the second ventilation hole is 10mm wide, with three rows of holes, the distance between the center of the hole belt and the mouth end is 33mm, and the air permeability is 1300CU; the distance between the centers of the two ventilation hole belts is 25mm, and the tipping paper and molding The paper is bonded and separated by the glue area. According to the ventilation degree of 66.1%, the single-ventilation cigarette and the double-ventilation cigarette are rolled. The physical parameters of the cigarette are tested by the Borgwatt comprehensive tester and the smoke analysis is carried out by the smoking machine. The open draw resistance of double-ventilated ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com