Sectional type additional heating device used for electronic direct cooling refrigerator

A direct-cooling refrigerator, compensation heating technology, applied in household refrigeration devices, lighting and heating equipment, applications, etc., can solve the problem of not being able to detect changes in the temperature of the refrigerating room in time, the rate of compressor not being turned on, and the inability of the main control board to effectively control Compressor startup, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

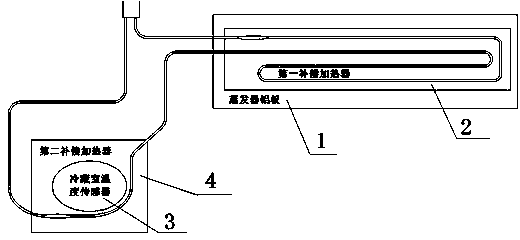

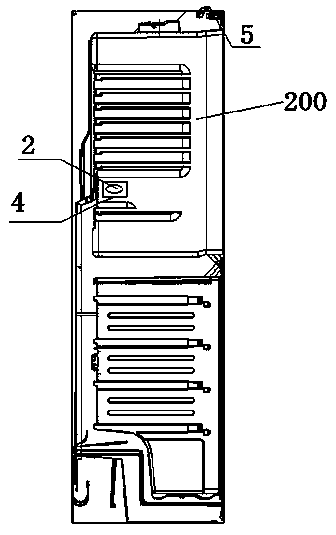

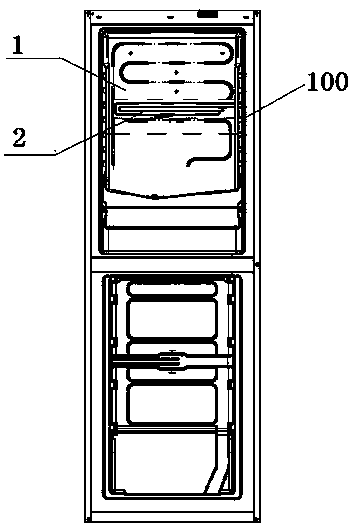

[0020] like figure 1 , figure 2 , image 3 As shown, a segmented compensation heating device for an electronic direct cooling refrigerator includes a first compensation heater 2 arranged on an aluminum plate 1 of an evaporator in a refrigerating chamber and a second compensation heater arranged around a temperature sensor 3 in the refrigerating room device 4. The first compensation heater 2 is pasted on the aluminum plate 1 of the evaporator on the back 100 of the refrigerator compartment by 3M glue. The second compensation heater 2 is pasted on the refrigerating chamber inner tank around the refrigerating chamber temperature sensor 3 by 3M glue. The first compensation heater 2 and the second compensation heater 4 are both electric heating wires. Considering that the temperature sensing accuracy of the refrigerating room temperature sensor 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com