A preparation method and application method of hydrogel for intelligent temperature control

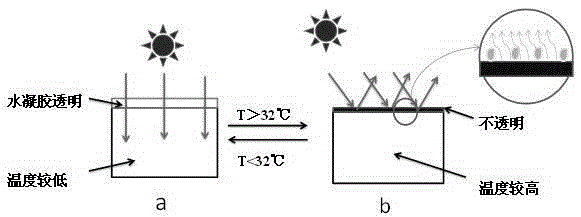

A technology of intelligent temperature control and application method, applied in the field of polymer technical materials, can solve the problems of inability to adapt to rapid changes in the environment, and achieve the effect of good recycling performance, excellent heat dissipation performance, and rapid heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] A method for preparing a hydrogel for intelligent temperature control of the present invention, the preparation method comprises the following process: adding N-isopropylacrylamide monomer, cross-linking agent, and distilled water into a beaker, ultrasonicating for 5 minutes, so as to dissolve Completely, add the initiator and initiator catalyst, pour it into the mold quickly after 5 minutes of ultrasonication, control the temperature at a constant temperature of 15°C~25°C, and react for 2 to 5 hours to form a cross-linked water gel. The mass ratio of crosslinking agent to N-isopropylacrylamide is 1:20-50. The mass ratio of initiator to N-isopropylacrylamide is 1:50-100. The mass ratio of initiator catalyst to initiator is 1:1-2. The mass ratio of distilled water to N-isopropylacrylamide is 3-4:1.

[0025] As a preferred method, the crosslinking agent is N,N-methylenebisacrylamide. The initiator is persulfate or benzoyl peroxide. The initiator catalyst is N,N,N',N'...

Embodiment 1

[0045] Weigh 5.0g of NIPAM, 0.1g of N,N-methylenebisacrylamide, 20ml of distilled water, add to a beaker to dissolve completely, add 0.0625g of ammonium persulfate to dissolve completely, add N,N,N',N'-tetramethyl Diethylamine 0.03125g, the solution was added to the mold within 30 seconds to react for four hours, after the reaction was completed, rinsed with distilled water three times, and phase-transformed three times at 25°C and 40°C to form a hydrogel.

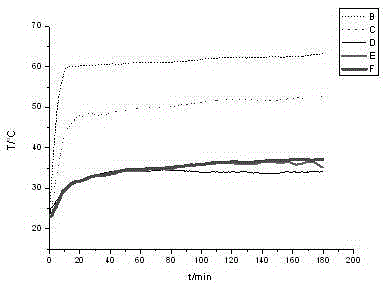

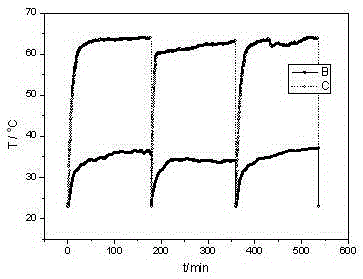

[0046] Light transmission performance test of hydrogel. Test process: Place the blue plastic needle under the prepared arc-shaped smart hydrogel to observe the light transmittance of the hydrogel; heat the hydrogel at 40°C, and place the blue needle under the hydrogel after ten minutes to observe Hydrogel light transmission. Test results such as figure 2 shown. figure 2 The middle ordinate represents temperature, and the abscissa represents time. The test result is figure 2 The line represented by D in . From fi...

Embodiment 2

[0051] Weigh 5.0g of NIPAM, 0.15g of N,N-methylenebisacrylamide, 17.5ml of distilled water, add to a beaker to dissolve completely, add 0.0625g of ammonium persulfate to dissolve completely, add N,N,N',N'- Add 0.03125 g of methyldiethylamine into the mold within 30 seconds, and react for three hours. After the reaction, rinse with distilled water three times, and undergo three phase transitions at 25°C and 40°C to form a hydrogel.

[0052] The light transmission performance and water content of the hydrogel were tested. The measurement method is as shown in Example 1. The measurement results are shown in Table 1. The hydrogel of this example appears to be light-transmissive and recyclable greater than one hundred times.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com