Ball joint three-dimensional shaft

A ball joint, three-dimensional technology, applied in the field of ball joint transmission mechanism, to achieve the effect of strong practical value, ingenious mechanism and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

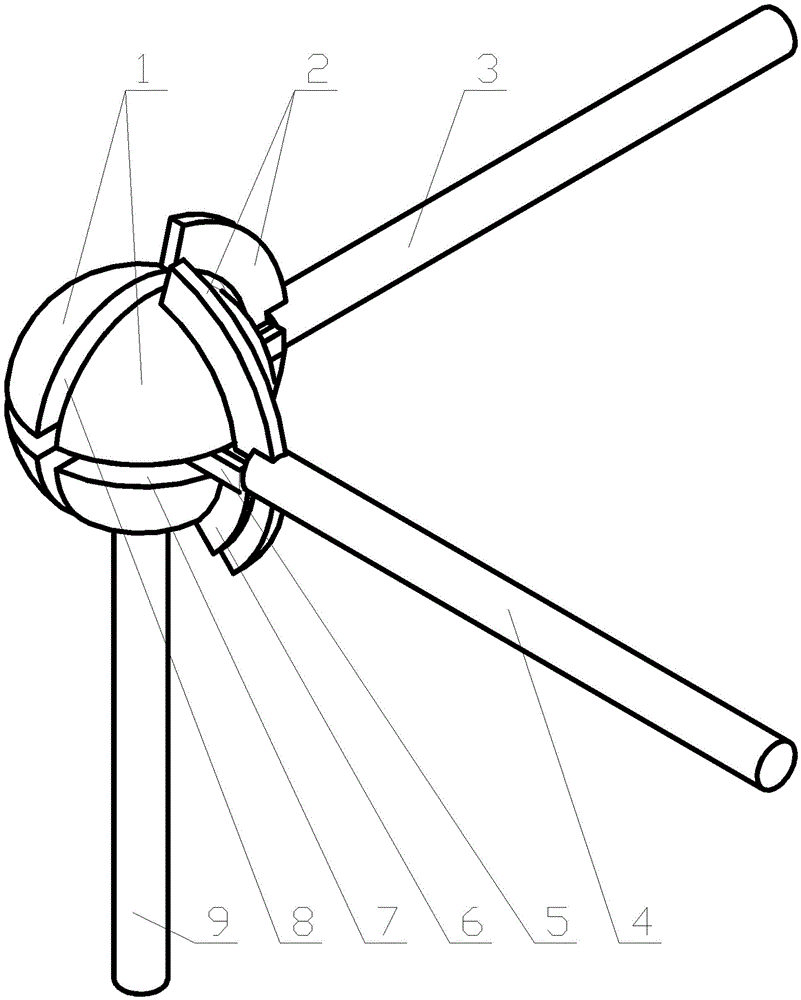

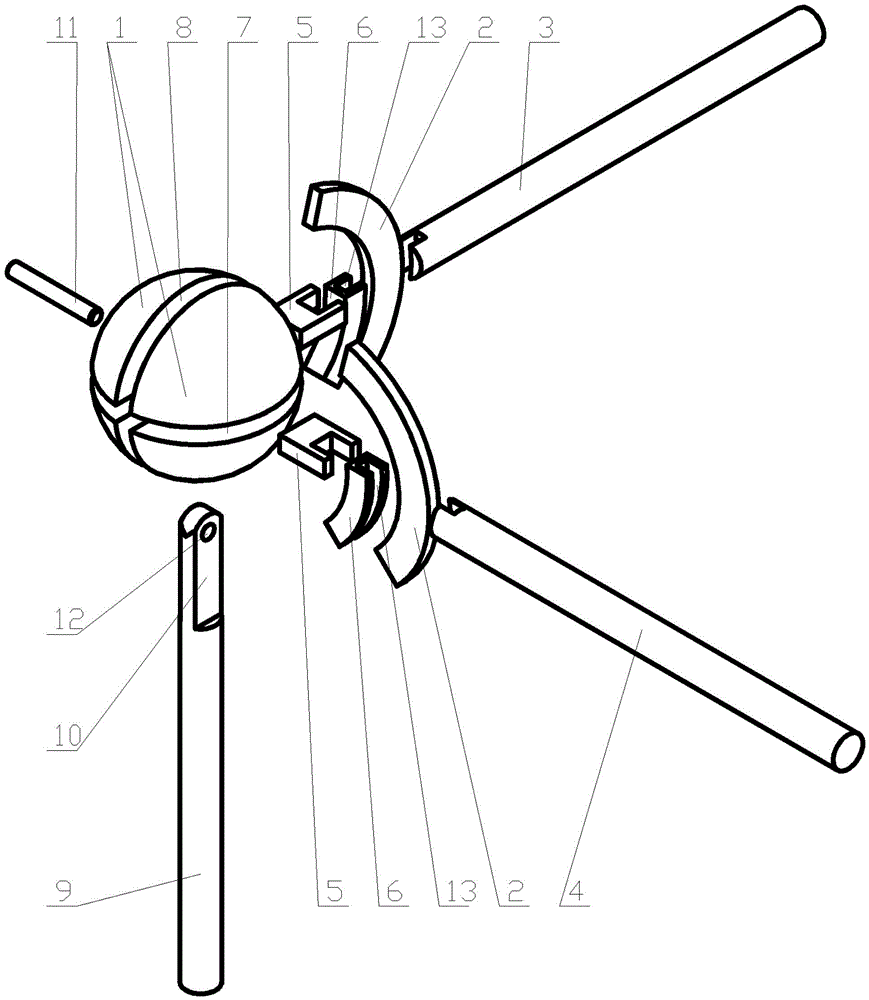

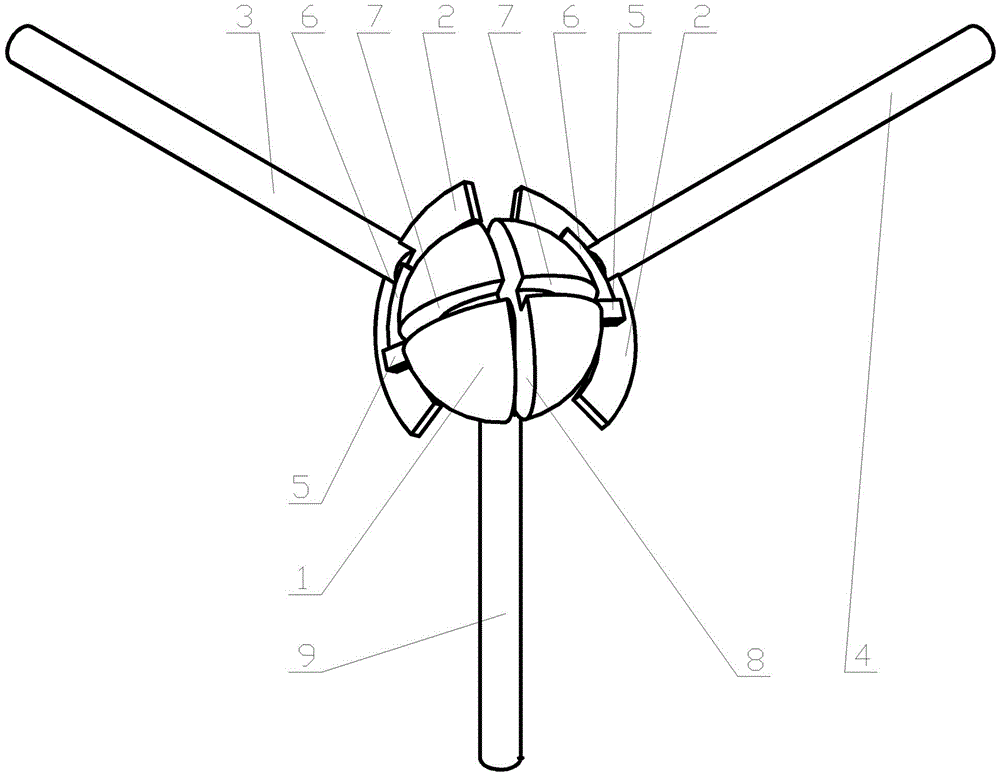

[0024] exist Figure 1 to Figure 4 Among them, it represents the structural composition of the present invention and the connection and positional relationship of the parts. The three-dimensional axis of the ball joint includes a ball 1, a slider 5, a moving slideway 6, a slider 2, an X axis 4, a Y axis 3, a Z axis 9 and Pin 11; sphere 1 is provided with Z-axis chute 8 and XY-axis chute 7, Z-axis chute 8 and XY-axis chute 7 are square grooves, 360 degrees are distributed on sphere 1, Z-axis chute 8 The position is vertically placed, the position of the XY axis chute 7 is perpendicular to the Z axis chute 8; the Z axis 9 is placed vertically, the upper end of the Z axis 9 is set as the Z axis slider head 10, and the two The side surface is in contact with the two sides of the Z-axis chute 8 on the sphere 1 and forms a clearance fit; a pin hole 12 is provided in the XY-axis chute 7 and on the Z-axis slider head 10, and a pin 11 is inserted into the pin hole 12. The pin 11 is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com