A Realization Method of Visual Extensometer Based on Digital Speckle

A realization method, digital speckle technology, applied in measuring devices, instruments, optical devices, etc., can solve problems such as the difficulty of making different marks, and achieve the effect of wide application range, high measurement efficiency, and simple spraying work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings.

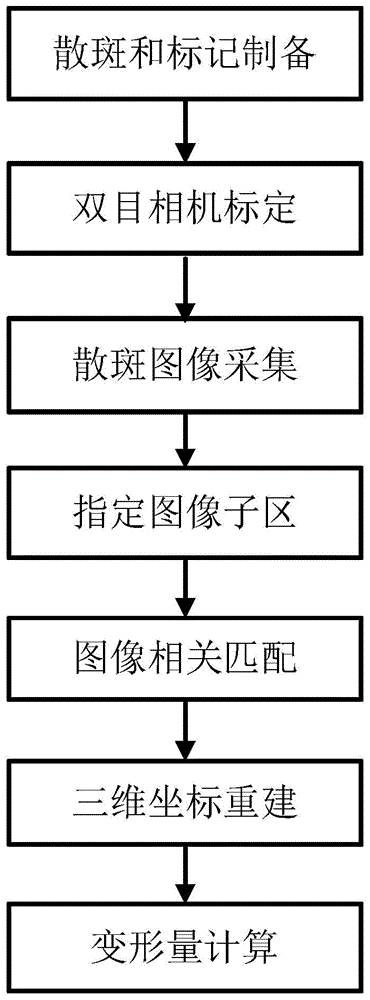

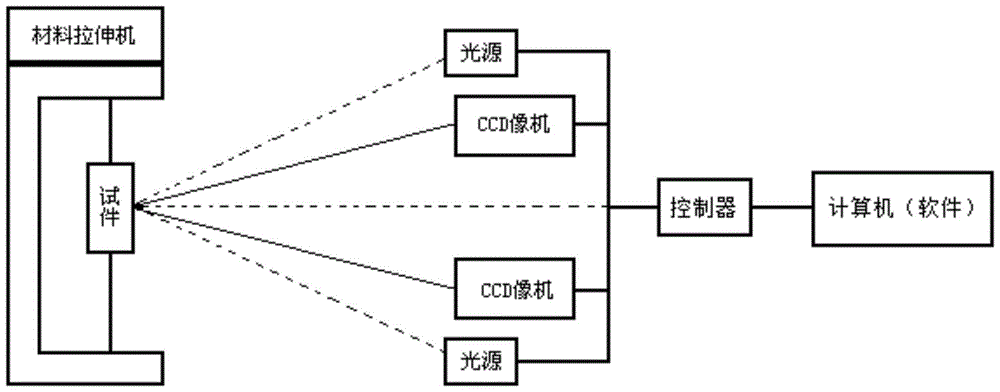

[0025] The present invention proposes a digital speckle-based visual extensometer implementation method, the specific operation steps are as follows figure 1 shown. The hardware device structure adopted is as follows: figure 2 As shown, it is mainly composed of 2 CCD cameras, 2 LED lights, 1 controller and 1 computer.

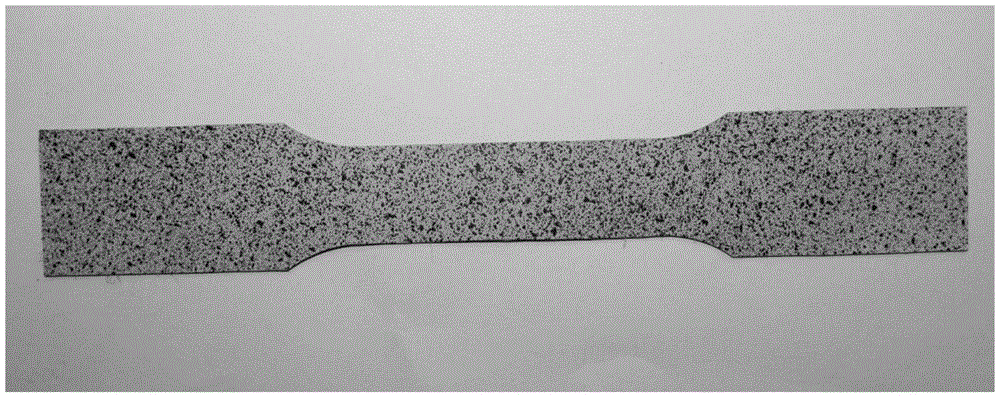

[0026] The first step, speckle and mark preparation: make speckle on the measurement area on the surface of the sample to be tested, and mark two calculation points (that is, the measured points) on the surface of the sample with black cross lines. Preferably, the preparation requirements: (a) the speckle particles sprayed on the surface of the sample should be randomly distributed; (b) the speckle contrast is obvious and should be greater than a predetermined threshold; (c) the speckle preparation range should be larger than the measured d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com