Vision measurement method for anisotropic performance parameters in sheet forming

An anisotropic and visual measurement technology, applied in the field of mechanical processing, can solve the problems of large workload, low efficiency and low precision, and achieve the effect of short measurement cycle, simple work and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] The present invention proposes a method for measuring the anisotropic performance parameters of sheet metal, and the specific operation steps are as follows: figure 1 shown. The hardware structure of the experimental device used is as follows: figure 2 As shown, it is mainly composed of 1 material tensile testing machine 1, sheet metal sample 2, 2 CCD cameras 3, 2 LED lights 4, 1 controller 5 and 1 computer 6, etc.

[0075] The first step is sample preparation, cutting the sheet blank into samples that meet the standard size and geometric shape requirements (GB / T5027-1999), a group of experimental samples cut from a certain clad sheet such as image 3 shown. Create speckle patterns on the surface area of the sample to be measured by artificial spraying. Requirements for the preparation of sheet metal samples: a) It should be ensured that the edge of the prepared sample is free of cracks, and the surface should not have defects such as scratches; b) The surface of...

Embodiment 2

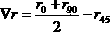

[0084] The implementation steps of this example are the same as Example 1. The sample material used in this example is AA6061 (aluminum material), and the sample size is as follows: image 3 shown. Utilize the true stress-strain curve of the AA6061 sample that the inventive method obtains as Figure 8 shown, according to Figure 9 The straight line between the true strain in the length direction and the true strain in the width direction obtained by the interval regression fitting shown in the figure shows the slope m =-0.39755, and then calculated r =0.65989.

Embodiment 3

[0086] The implementation steps of this embodiment are the same as in Example 1. The sample material used in this embodiment is SPCC (cold-rolled low-carbon steel), and the sample size is as follows image 3 shown. Utilize the true stress-strain curve of the SPCC sample that the inventive method obtains as Figure 10 shown, according to Figure 11 The straight line between the true strain in the length direction and the true strain in the width direction obtained by the interval regression fitting shown in the figure shows the slope m =-0.60718, and then calculated r =1.54570.

[0087] In order to verify the accuracy of strain calculation from digital speckle images, the Figure 12 The image acquisition device shown is designed and realized the standard tensile test of steel specimens, and the accuracy verification and comparison are carried out by using the extensometer, as shown in Figure 13 As shown, the index values decrease from the inside to the outside on the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com