variable thrust drill

A technology of variable thrust and drill body, which is applied to drill bits, drilling equipment, earthwork drilling and production, etc., and can solve problems such as inability to achieve stable positioning of movable drill bits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

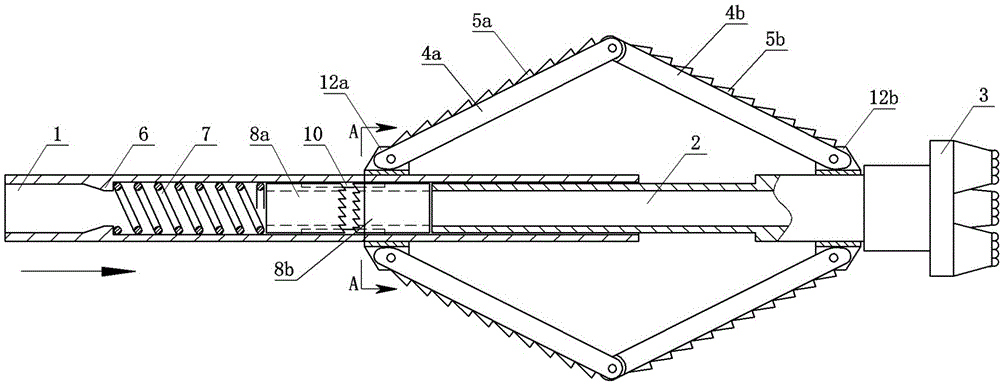

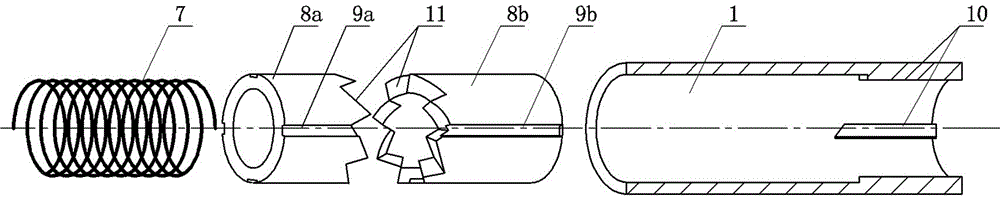

[0016] Example 1: A variable thrust reducing drill, see figure 1 , The outer drill rod 1 and the inner drill rod 2 are nested with each other, and a structure that can only slide axially is provided between the two, such as spline fitting, or a concave groove matching the guide rib 10 is provided on the outer side wall of the inner casing groove.

[0017] A fixed drill bit 3 is installed at the front end of the inner drill rod 2, and a movable drill bit is arranged between the outer drill rod 1 and the inner drill rod 2.

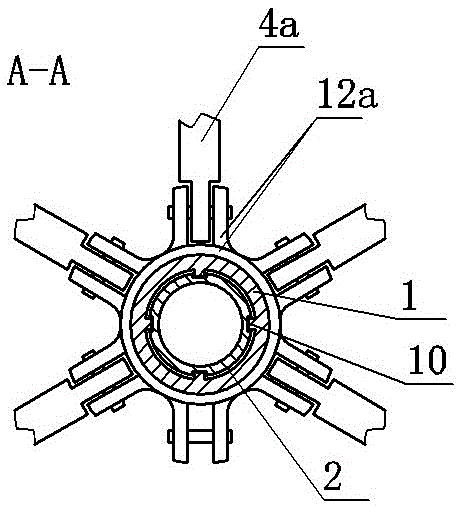

[0018] figure 1 Among them, the movable bit includes multiple sets of drill body one 4a and drill body two 4b, and supports 12a and 12b are fixed on the outer side of the outer drill rod 1 and the inner drill rod 2, respectively. The ends of the drill body one 4a and the drill body two 4b of each group are hinged on the supports 12a and 12b through pins, respectively. The other ends of each drill body 4a and drill body 2 4b are hinged together by a pin.

[0019] ...

Embodiment 2

[0021] Embodiment 2: Another variable thrust reducing drill, the drawings are not drawn, the content is basically the same as the embodiment, the similarities are not repeated, the difference is: the inner drill rod is located at the rear end and the outer drill rod is located at the front end, fixed The drill rod is arranged at the end of the outer drill rod.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com