An anti-copper column pressure leakage device and automatic copper column pressing machine

A technology of copper pillars and pressure leakage, which is applied in the field of machinery, can solve the problems that it is difficult to ensure that the copper pillars must be pressed into the notebook case or mobile phone case, the suction is not enough, and the copper pillars fall off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

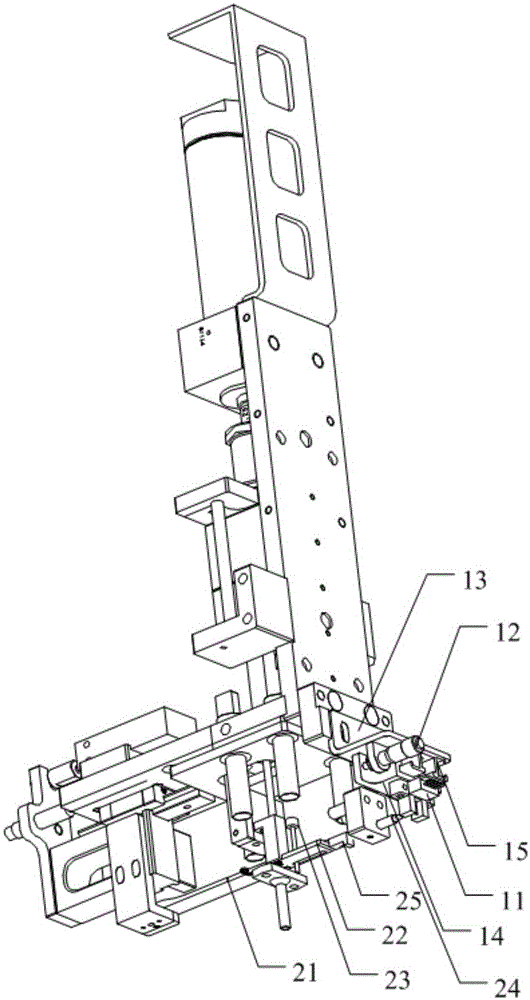

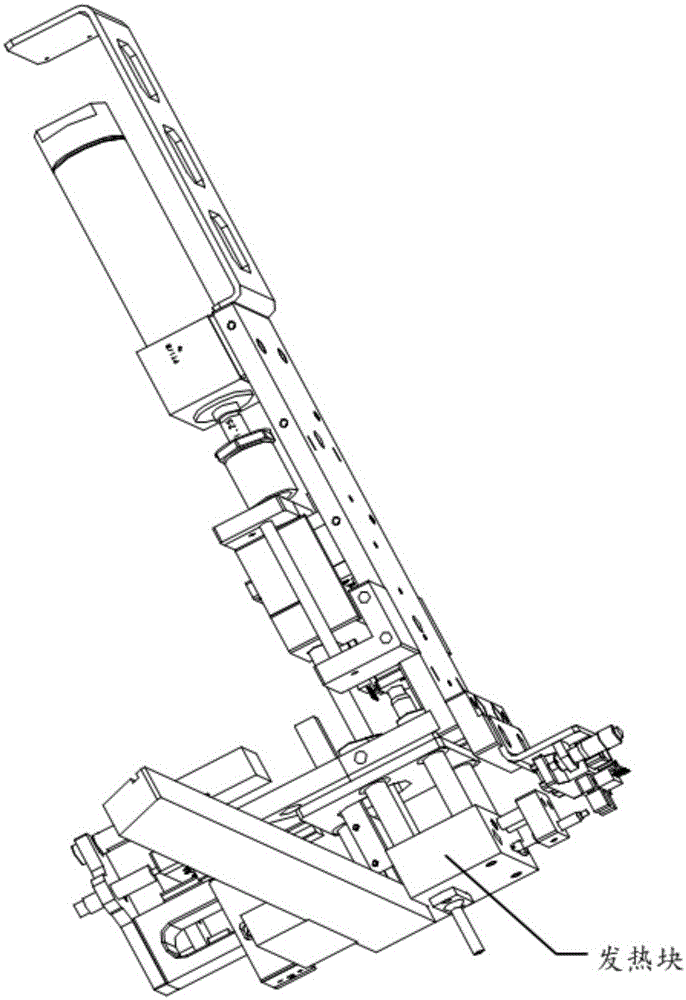

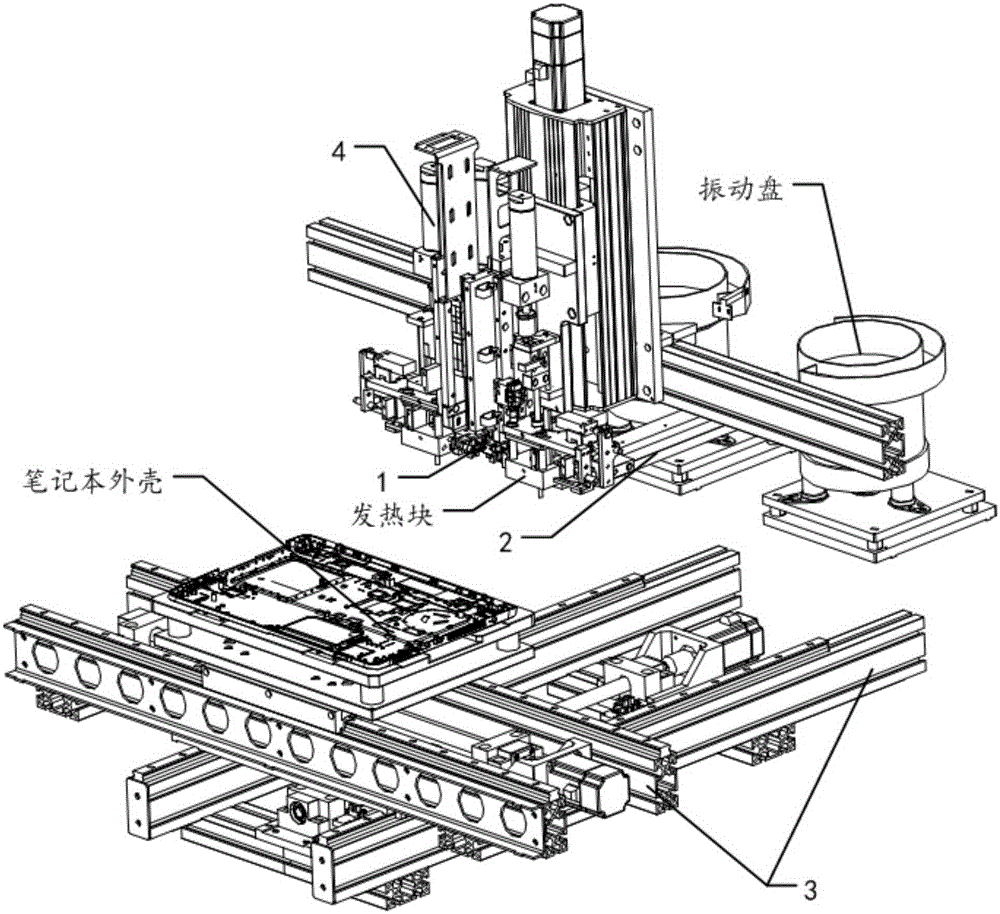

[0045] The embodiment of the present invention discloses an anti-copper column pressure leakage device and an automatic copper column pressing machine, which detects whether the copper column exists on the copper column push piece through the sensor, and uses the method of moving distance difference generated by the copper column push piece , It can conveniently realize the detection of whether the copper column is leaked and filled, and timely supply the copper column to the place for filling and pressing, which can improve the production quality and reduce the heavy work hours of the subsequent copper column.

[0046] The technical solutions in the embodiments of the present invention will be described clearly and in detail below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only part of the embodiments of the present invention, not all of them. Based on the embodiments of the present invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com