A non-pyrotechnic unlocking and releasing mechanism

A release mechanism and non-pyrotechnic technology, which is applied in the direction of aerospace vehicle docking devices, etc., can solve problems such as high impact force, pollution, and influence on aircraft attitude, and achieve high temperature resistance, simple structural design, and avoid debris pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

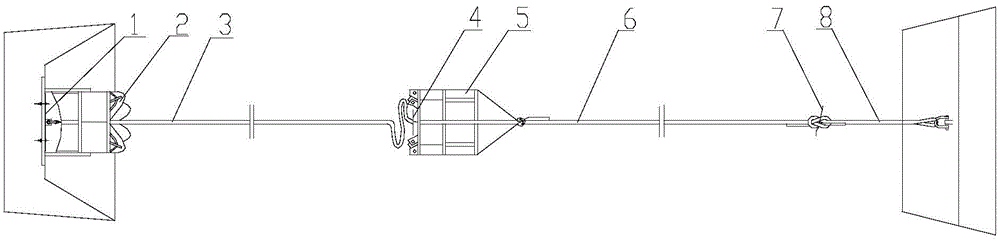

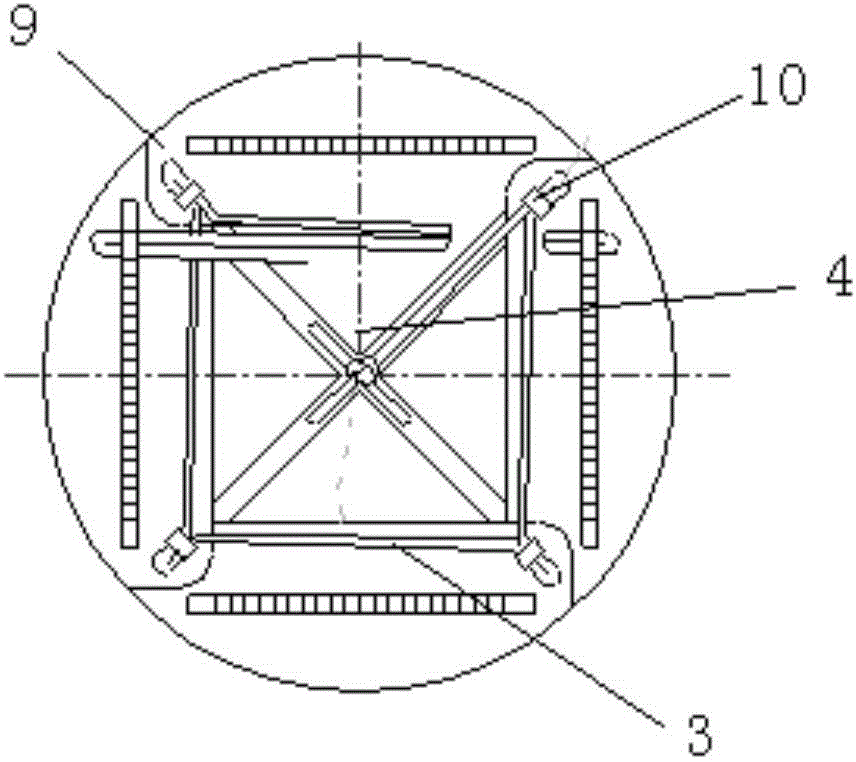

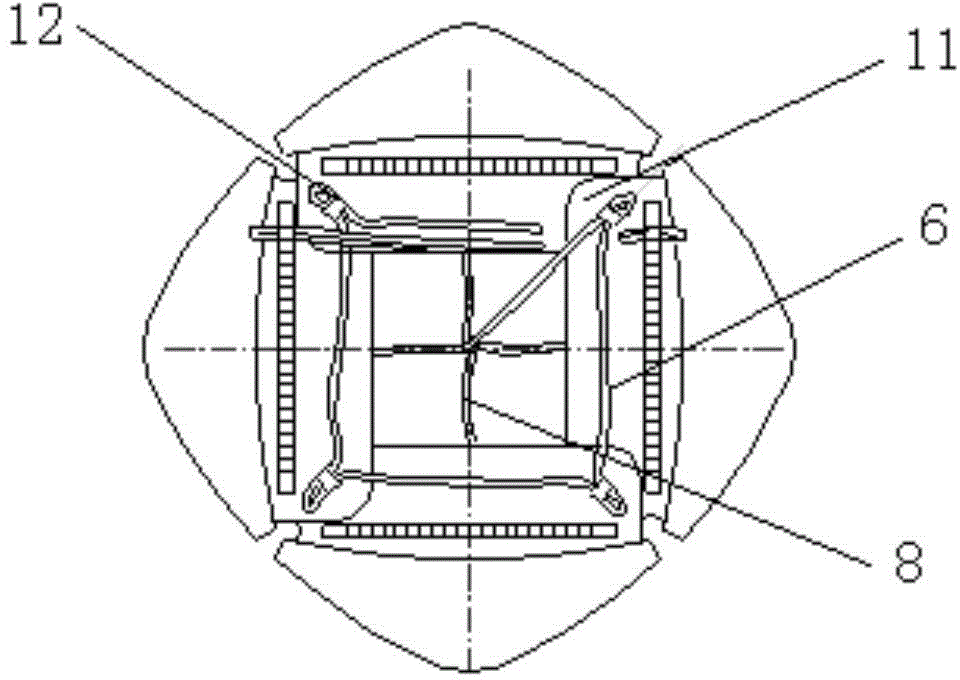

[0017] The present invention will be further introduced below in conjunction with the accompanying drawings.

[0018] An unlocking and releasing mechanism in a non-pyrotechnic manner, comprising a bottom plate 1, an outer bag 2, a drawstring a3, a cover sheet 4, an inner bag 5, a drawstring b6, a sealing rope 7, and an unlocking drawstring 8, wherein the bottom plate 1 is installed in the outer bag 2 At the bottom, the outsourcing 2 and the bottom plate 1 are installed and fixed on one end of the separation compartment through nuts, the bottom plate 1 is provided with a suspension seat, one end of the drawstring a3 is connected with the suspension ring, the other end is connected with the cover piece 4, and the suspension ring is connected with the suspension seat; One end of the unlocking stay rope 8 is connected to the separation cabin section, the other end is connected to the drawstring b6, the other end of the drawstring b6 is connected to the sling connected to the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com