torque transfer device

A torque transmission device and torque technology, applied in the direction of electromechanical devices, magnetic circuit rotating parts, electrical components, etc., can solve the problems of high cost, high cost of rotor bracket, high cost of torque transmission device, etc., and achieve simple connection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

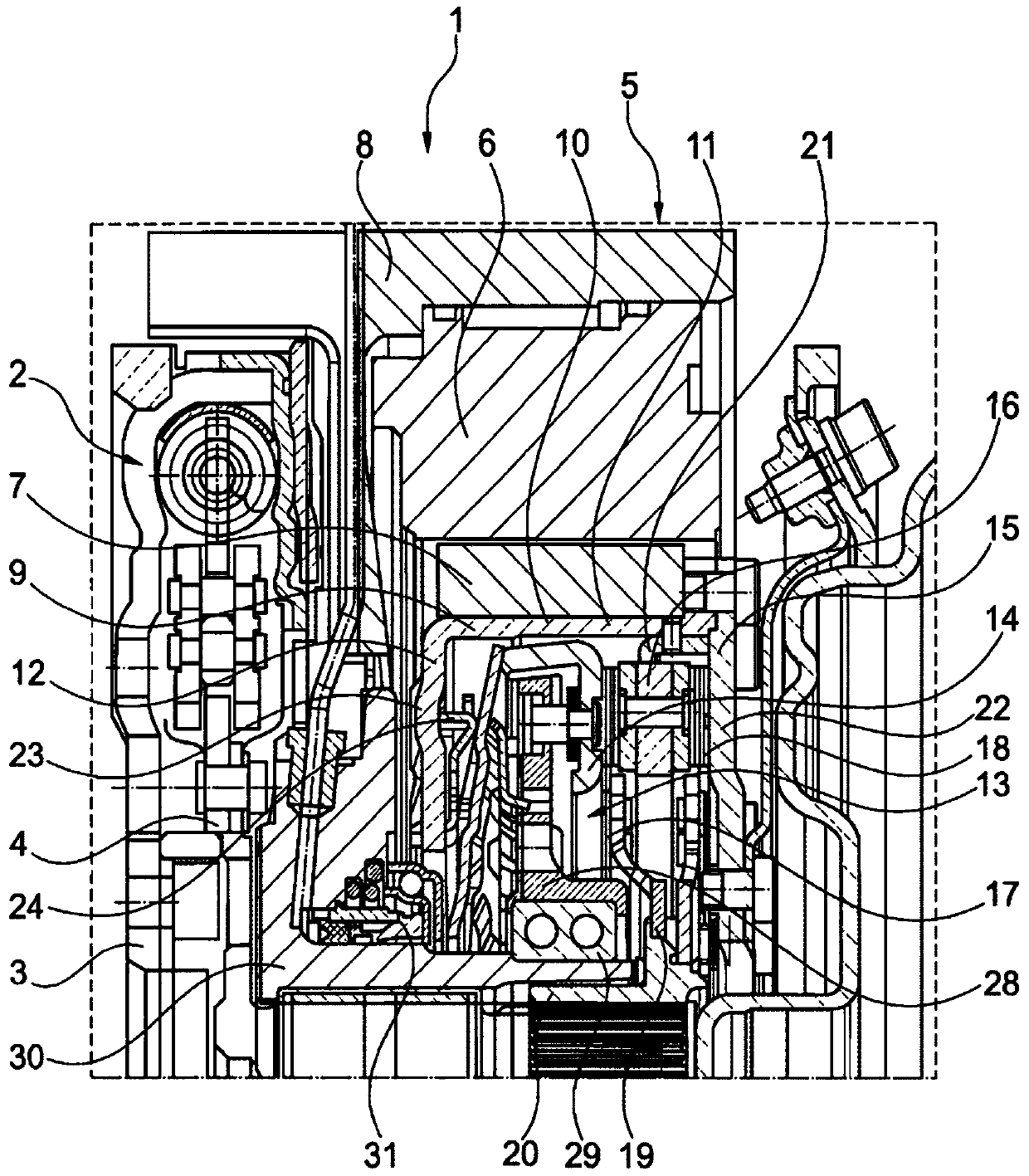

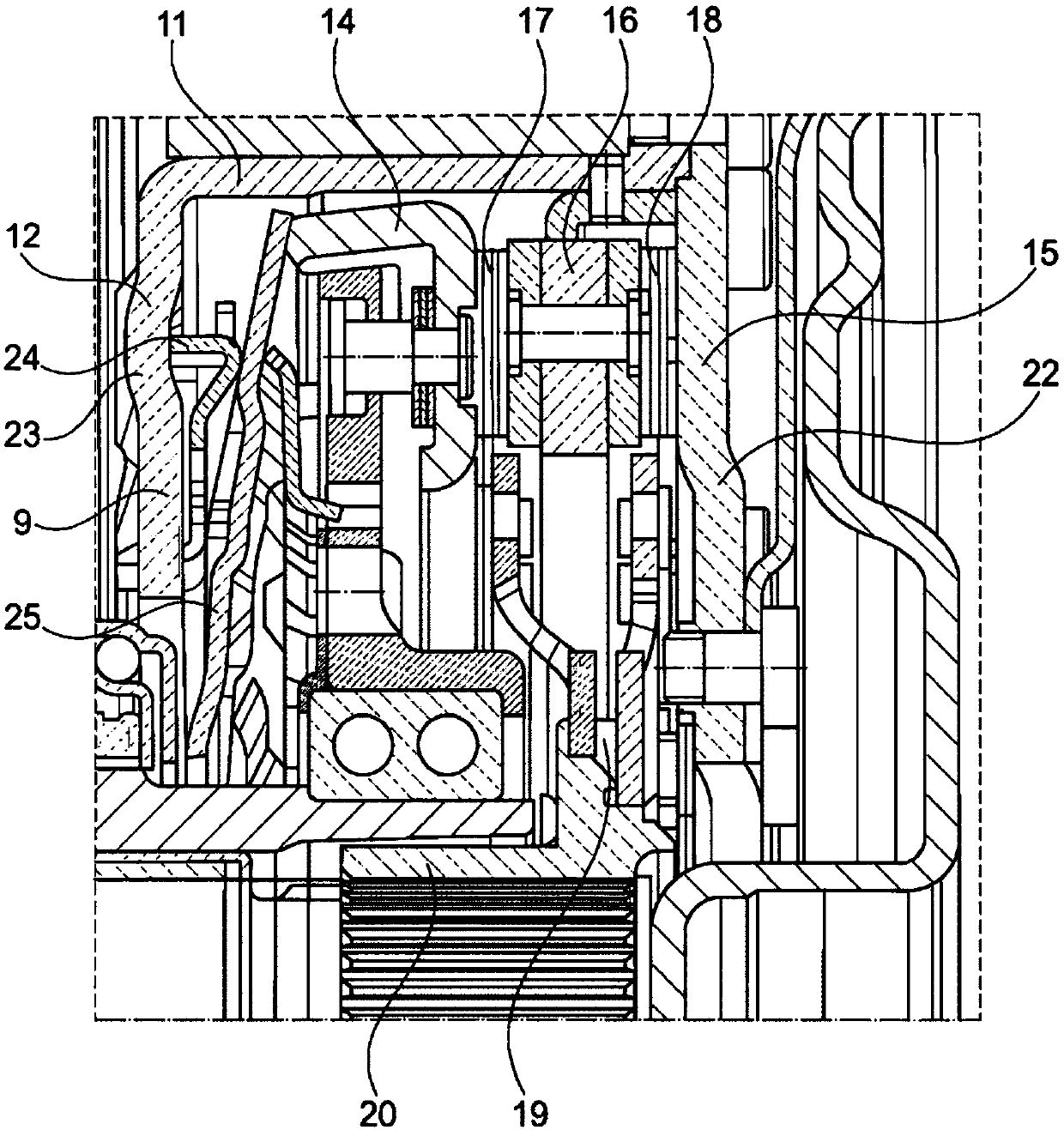

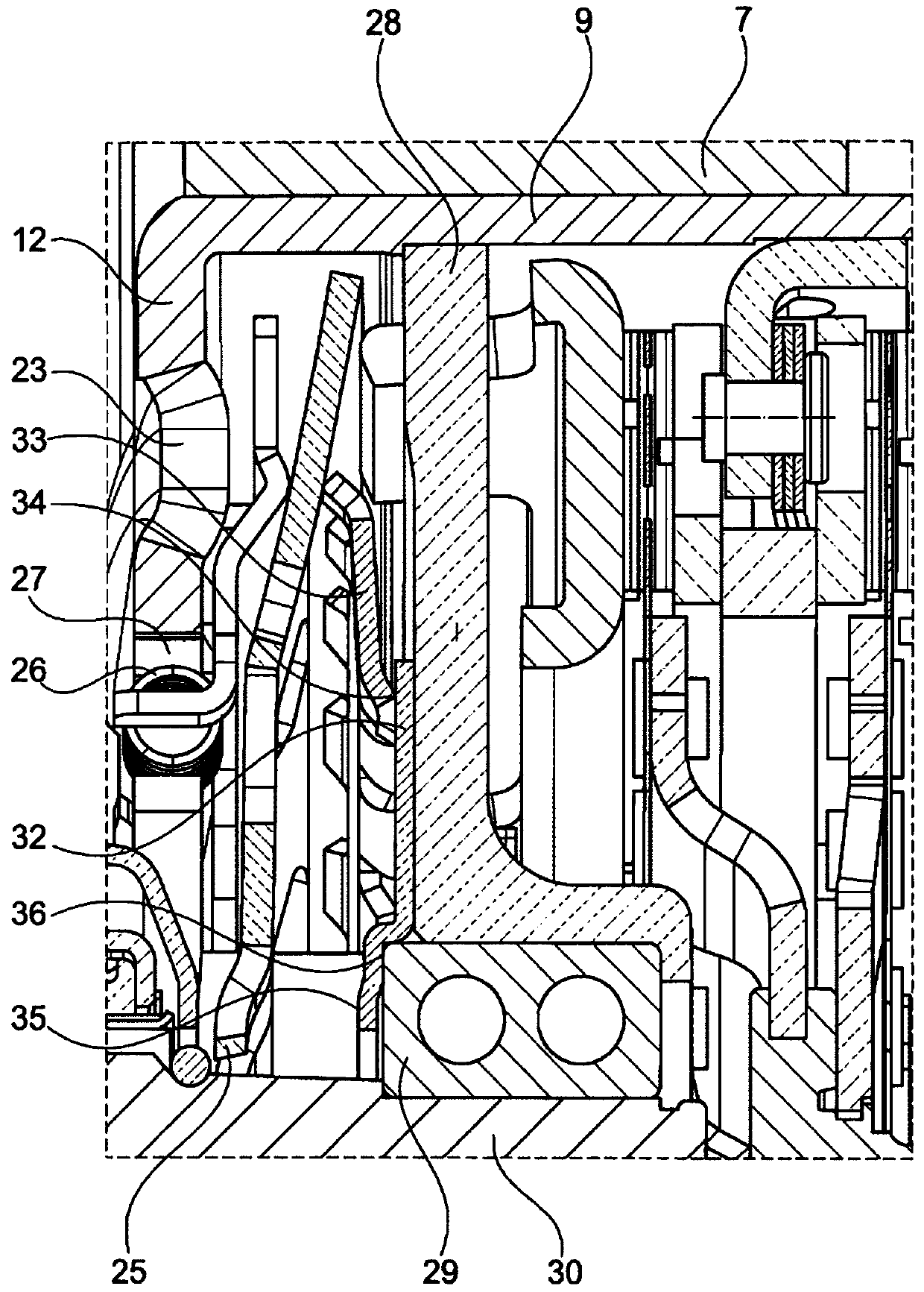

[0024] figure 1 A torque transmission device 1 is shown schematically with an input-side damping device 2 , wherein an input element 3 of the damping device 2 can be connected to an output element of an internal combustion engine. The output element 4 of the damping device 2 is preferably connectable to the transmission input shaft. The torque transmission device 1 also has an electric machine 5 , which is formed by a stator 6 and a rotor 7 . The stator 6 is carried here by a stator carrier 8 . In this case, the stator carrier 8 surrounds the stator 6 radially on the outside and fixes the stator 6 via the stator carrier 8 , for example in a sleeve of the torque transmission device 1 .

[0025] The rotor 7 is carried radially on the inside by a rotor carrier 9 . The rotor carrier 9 is designed here as a pot-shaped element 10 which has a first wall region 11 and a second wall region 12 . The first wall region 11 extends in the axial direction, wherein the second wall region ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com