A controllable superimposed bidirectional spinning device

A spinning device, a superimposed technology, applied in the field of controllable superimposed bidirectional spinning devices, can solve problems such as thermal decomposition, achieve uniform fibers, improve production efficiency, and overcome the effects of single spinning material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

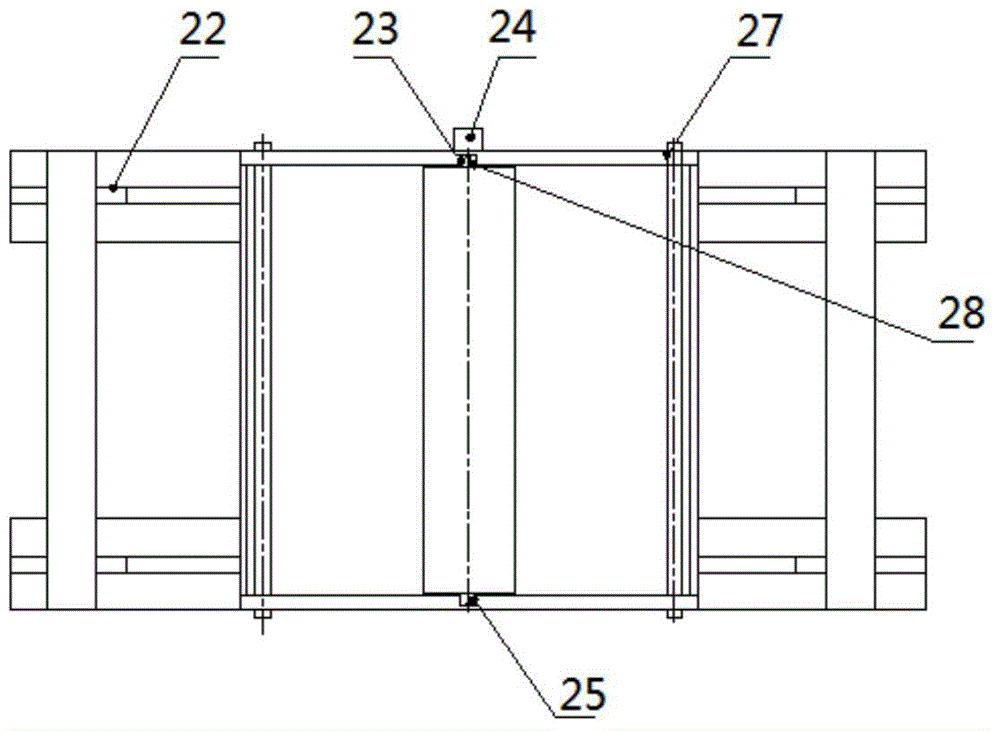

[0019] The present invention proposes a controllable superimposed bidirectional spinning device, such as figure 1 and figure 2 As shown, it includes high-voltage electrostatic generator 1, electrode plate 2, protective cover 3, rolling shaft 4, frame 5, upper material rod 6, roller 7, heating device 8, liquid collection tank 9, lower material rod 10, micro Motor 11, fiber collecting plate 12, guide rail 13, receiving net 15, main motor 24 and slide block 25.

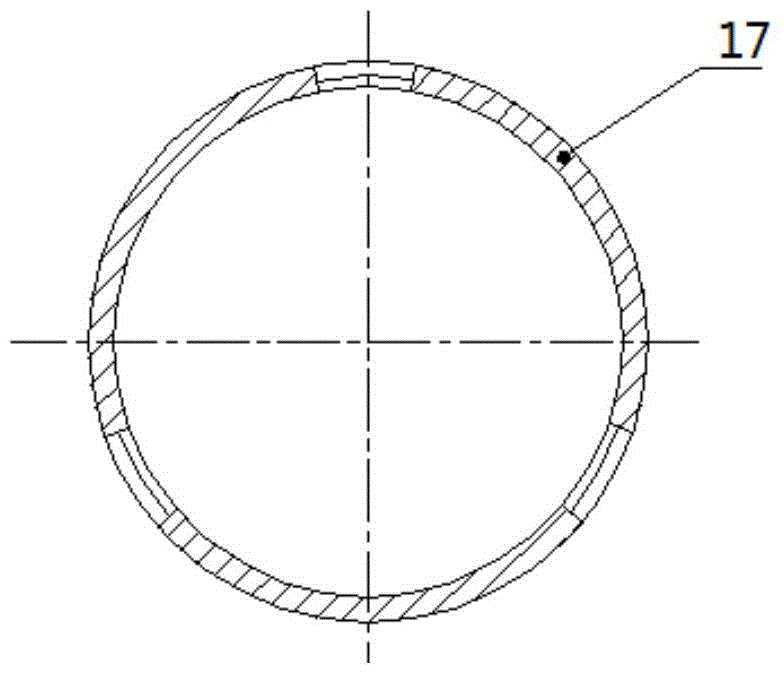

[0020] Firstly, the operator stays away from the protective cover 3, and turns on the power supply of the heater through computer control to keep the temperature at about 230°C. Such as Figure 4 , the heating device 8 through the telescopic ring 16 will image 3 The three heaters 17 shown are connected in series. When the roller 7 is installed, the heating device is circumferentially compressed and the diameter is reduced. Figure 6 The inner wall surface 18 of the roller as shown is closely attached, and then the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com