Cleaning apparatus

An instrument and cleaning technology, applied in the field of cleaning instruments, can solve the problems of time-consuming, unsatisfactory cleaning process results, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

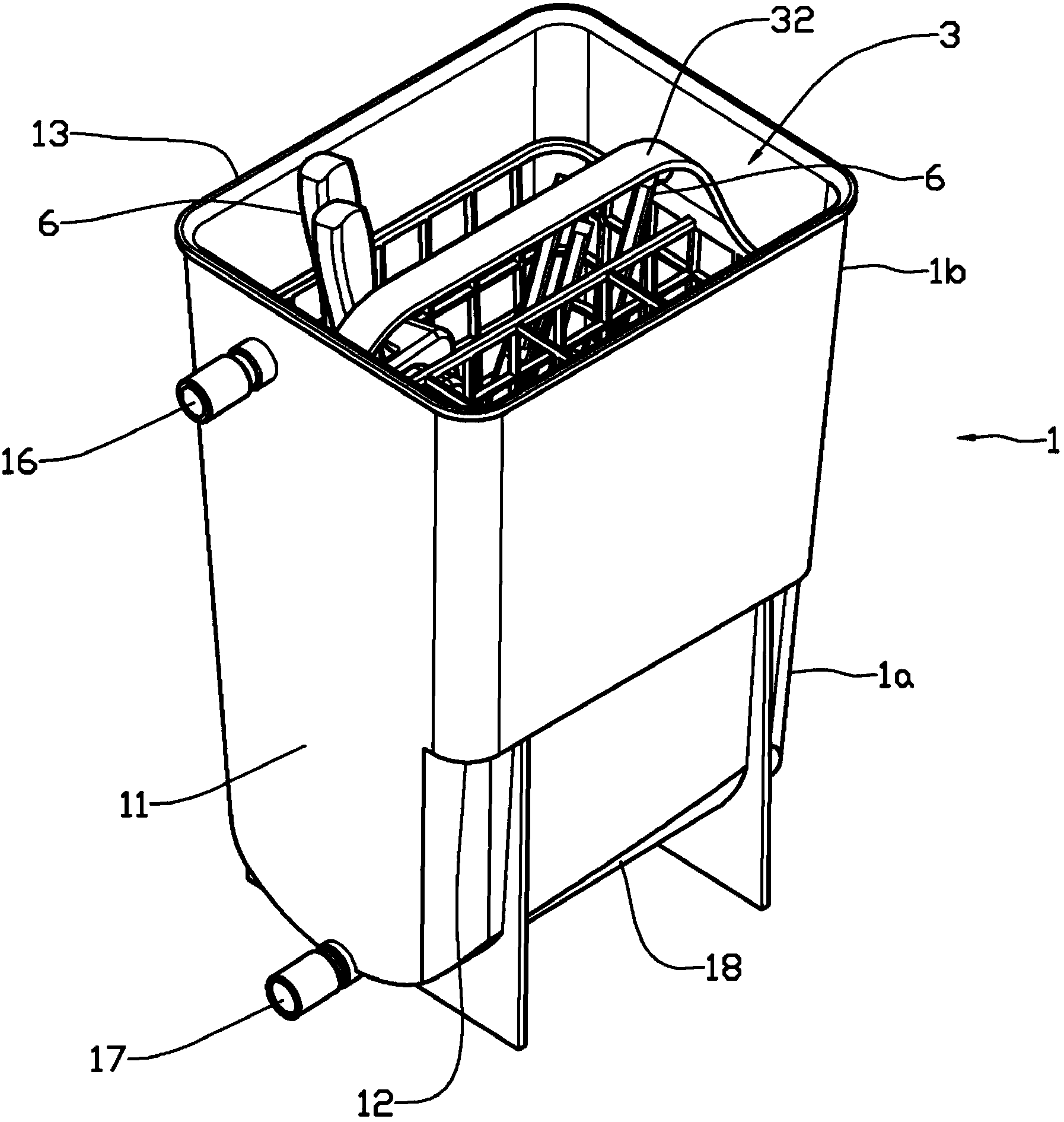

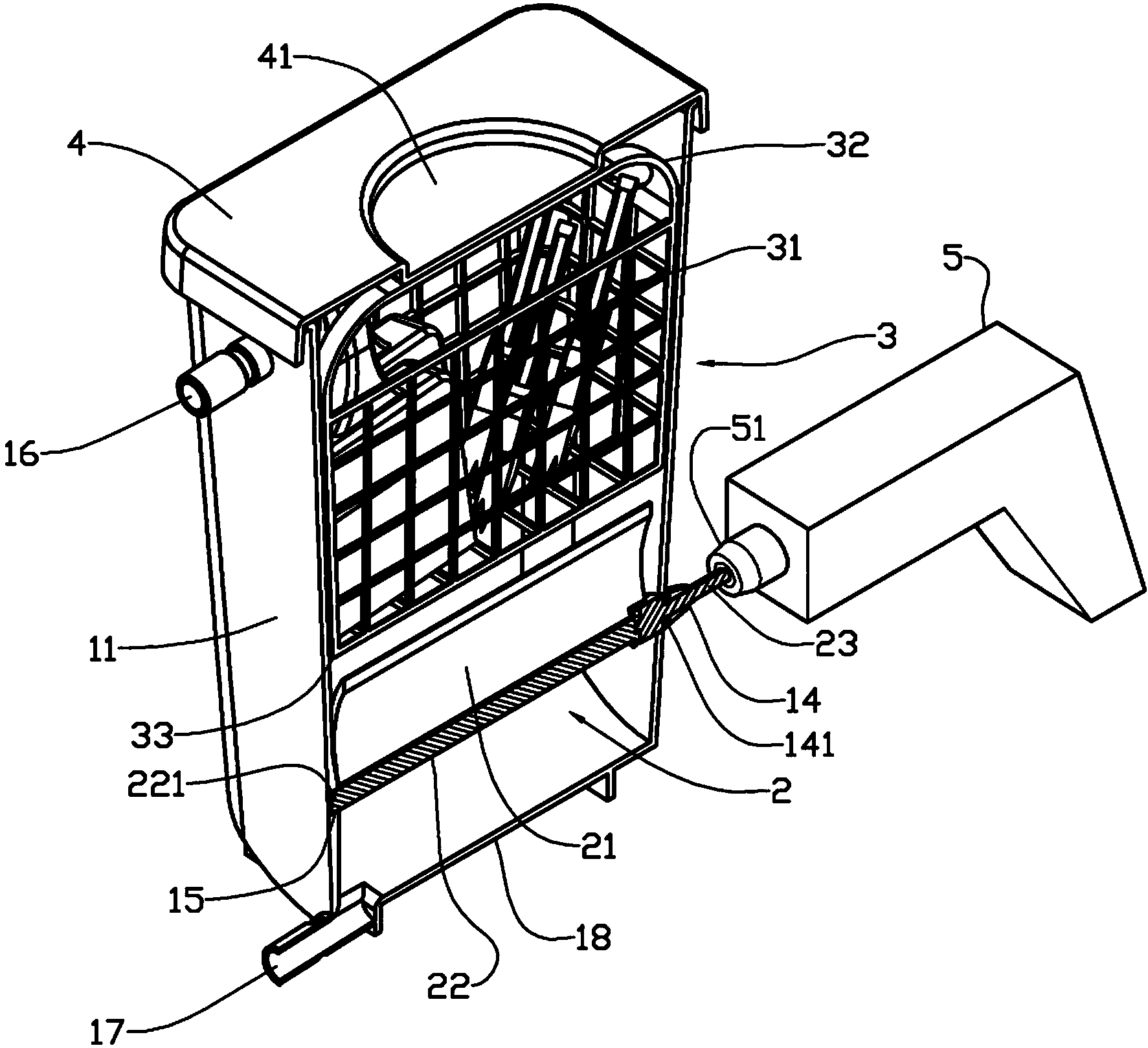

[0023] In the figures, reference numeral 1 is a container having an open top 13 arranged to be closed with a lid 4 . In the lower part la, the container contains the paddle wheel 2 . The upper part 1b of the container 1 is arranged to include means for securing items to be cleaned, here shown as a removable threaded basket 3 designed to keep brushes and other painting equipment standing upright. A drive device 5 , here schematically shown as an electric drill (drill bit) with a tool connector 51 (supporter), is connected to the drive shaft 23 protruding from the container 1 .

[0024] The paddle wheel 2 is arranged with a horizontal central shaft supported in recesses 15 of two opposing vessel side walls 11 . The bottom 18 of the container is arranged corresponding to the groove of the paddle wheel 2 , whereby the bottom 18 shows a defined clearance relative to the paddle wheel 2 . The tip of the paddle wheel 2 is kept at a prescribed distance from the side wall 11 . A driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com