Valve with implementable fine tuning of fluid flow

A technology of fluid flow and valve body, which is applied in the field of valve body for fine-tuning of fluid flow, and can solve problems such as difficulty in reaching the adjustment point, instability, and difficulty in controlling the amount of fluid adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] A valve body capable of fine-tuning fluid flow according to the present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments, but the explanation does not constitute an improper limitation on the technical solution of the present invention.

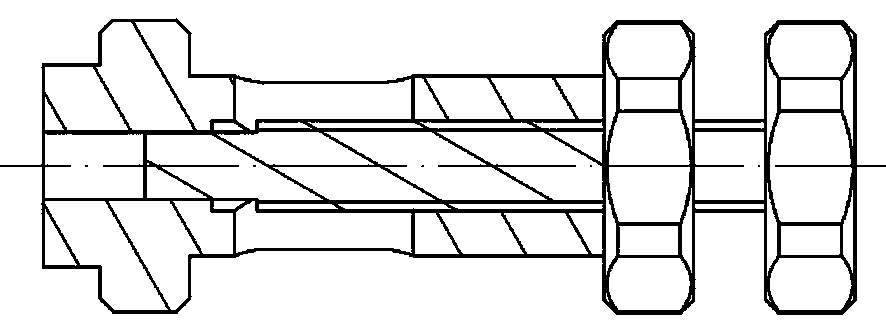

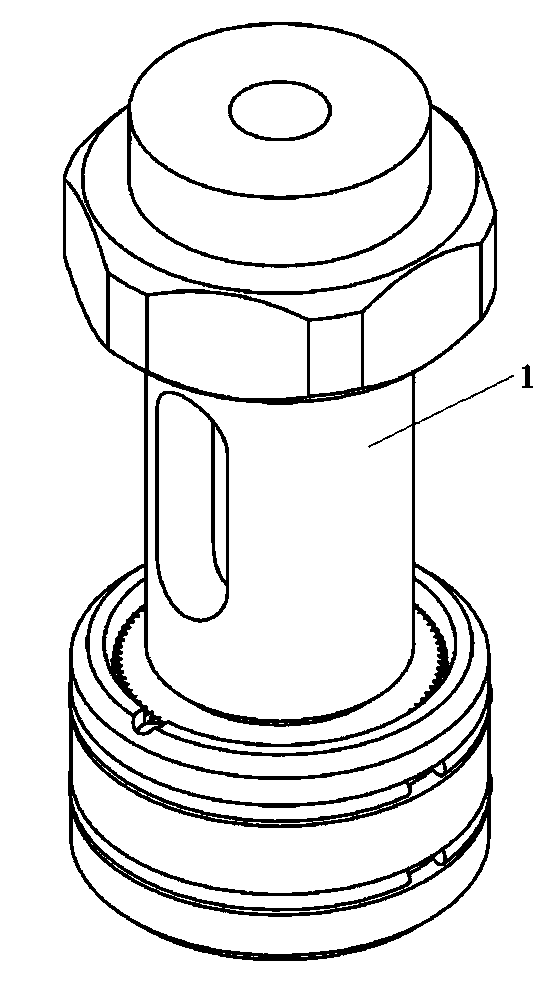

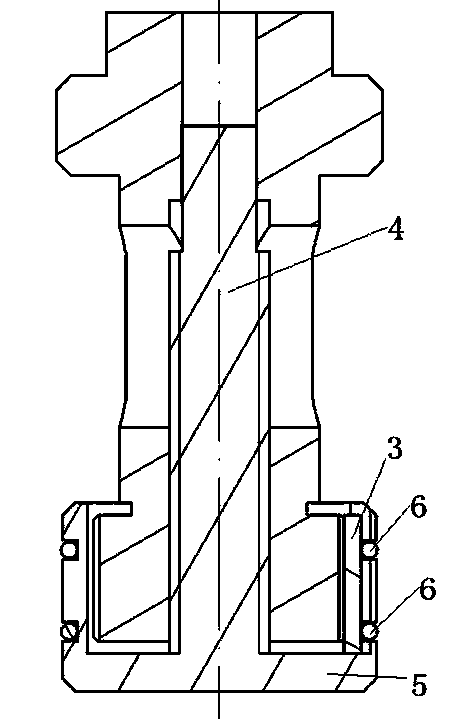

[0022] Figure 2 to Figure 4 The structure of the valve body capable of fine-tuning the fluid flow according to the present invention is shown in one embodiment.

[0023] Such as Figure 2 to Figure 4 As shown, the present invention relates to a valve body capable of fine-tuning fluid flow, which includes a valve body 1 , a screw adjustment mechanism and a fine-tuning mechanism, and the fine-tuning mechanism includes fine-tuning teeth 2 and a fine-tuning rolling cylinder 3 . The valve body 1 is a cavity, the lower end of the cavity is provided with the fine-tuning teeth 2 , the inside of the cavity is provided with threads, and the fine-tuning teeth include teeth and toot...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap