Hydraulic control check valve

A hydraulically controlled check valve and valve body technology, applied in the field of hydraulic control valves, can solve the problem that the opening of the hydraulically controlled check valve cannot be fine-tuned and controlled, and achieve the effect of fine-tuned flow control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

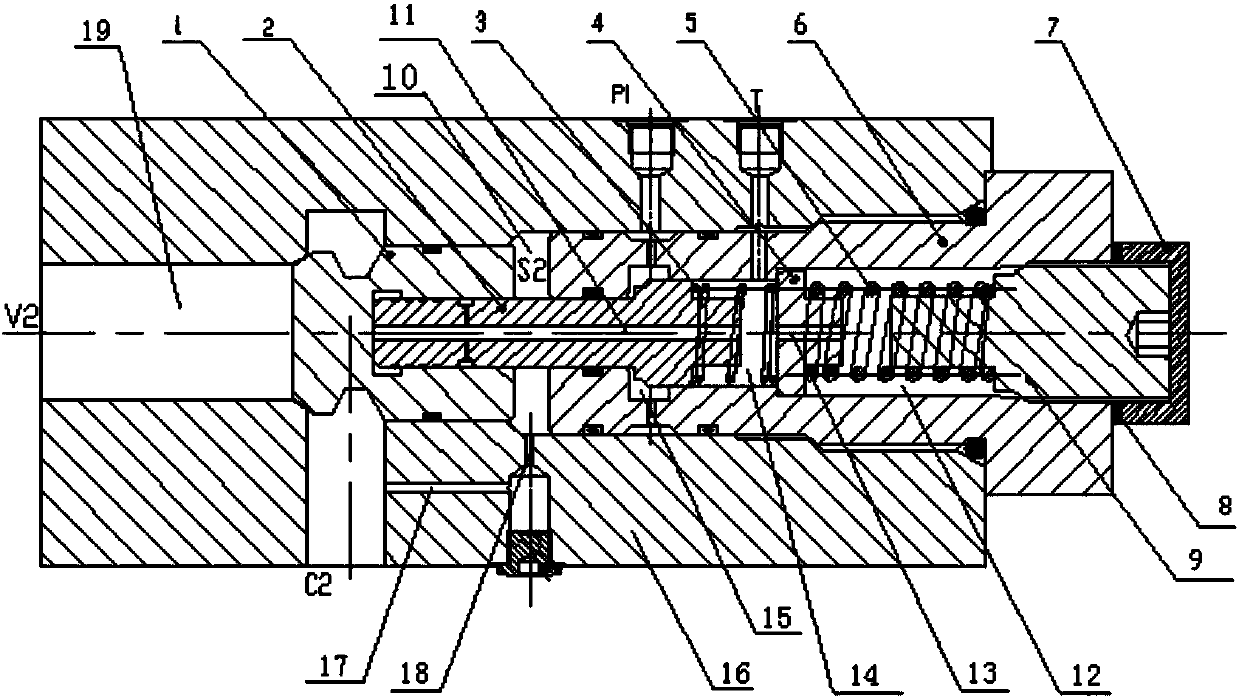

[0016] The specific implementation will be described below in conjunction with the accompanying drawings.

[0017] The hydraulic control check valve in the present invention includes a valve body 16, and a working oil passage 19 is arranged in the valve body. The flow from the working port to the working C2 oil port is forward flow, and the flow from the working C2 oil port to the working V2 oil port is reverse flow. The main spool 1 is arranged on the working oil passage 19, and the main spool 19 is located in the valve body. Axial slide is made in 16, and this axial direction is defined as left-right direction, main spool moves to the left, and working oil passage 19 times main spool cuts off and closes, and main spool moves to the right, and working oil passage 19 is opened.

[0018] A valve sleeve 6 is arranged in the valve body 1, and the valve sleeve 6 is inserted into the valve body 16 through a threaded connection. 4, pressure regulating spring 5, adjusting screw 9. ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap