Detection method for particle sizes of atomized droplets of feed liquid

A technology of atomized liquid droplets and detection methods, which is applied in the direction of measuring devices, particle size analysis, particle and sedimentation analysis, etc., can solve the problems that cannot reflect the uniformity of material liquid, etc., and achieve the effect of reliable technical parameters and evaluation data, and efficient evaluation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

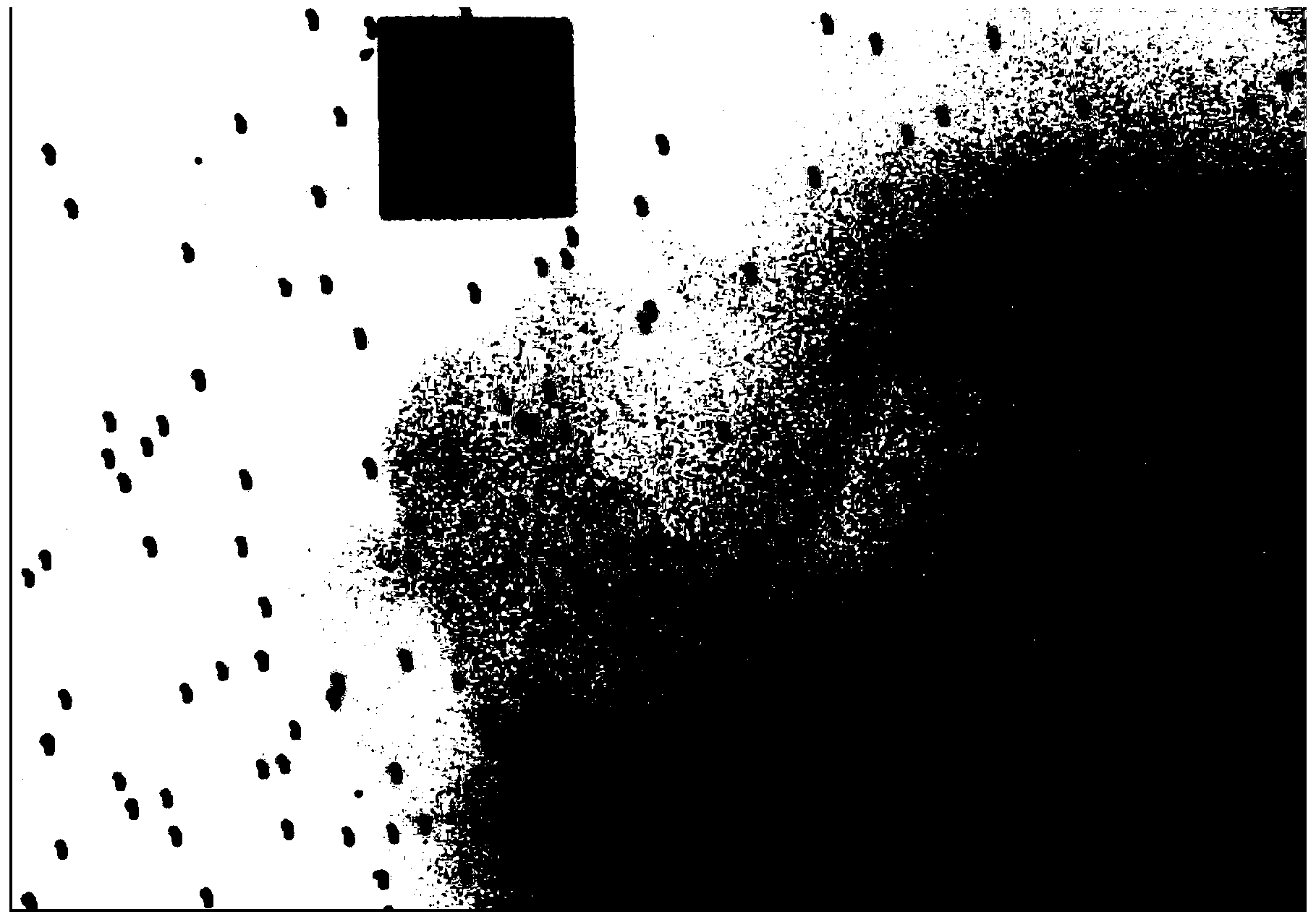

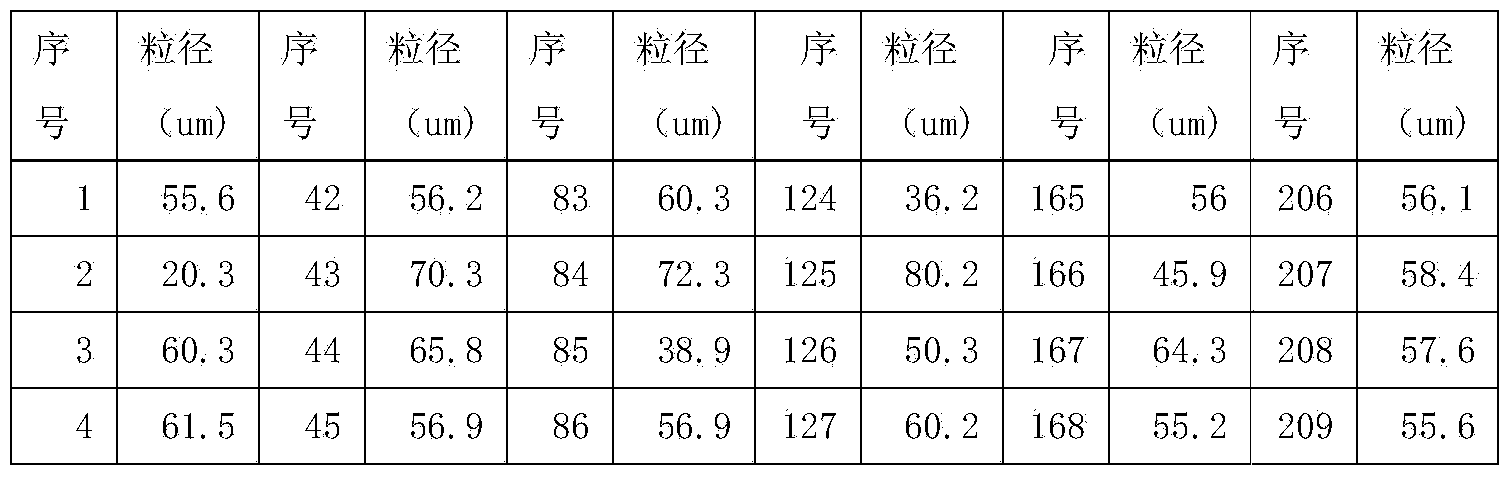

[0024] Take a circular object with a known area S0 as a standard object, and place it on a flat, smooth, opaque white background board. The feed solution was applied to the background plate and photographed. Open the photographic result in Image-proplus; use Image-proplus to select the measurement item and measurement area to obtain the corresponding pixel value. The image number of the standard object is represented by P 0 Indicates that the pixels that detect granular stems are denoted by P 1 express. S 1 The pixel calculation formula is S 1 =S 0 *P 1 / P 0 . The particle size D of a single particle stalk 1 =(4*S 1 / Pi) 0.5 . The calculated droplet size is shown in Table 1:

[0025] Table 1

[0026]

[0027]

[0028] The picture of the Image-proplus image processing of embodiment 1 sees figure 1 . The droplet size distribution diagram is shown in figure 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com